A paint spraying and coloring device for safety helmets

A safety helmet and rotating shaft technology, which is applied to spraying devices, typewriters, printing, etc., can solve the problems of slow spraying speed and uneven spraying of safety helmets, and achieve the effect of fast delivery of safety helmets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

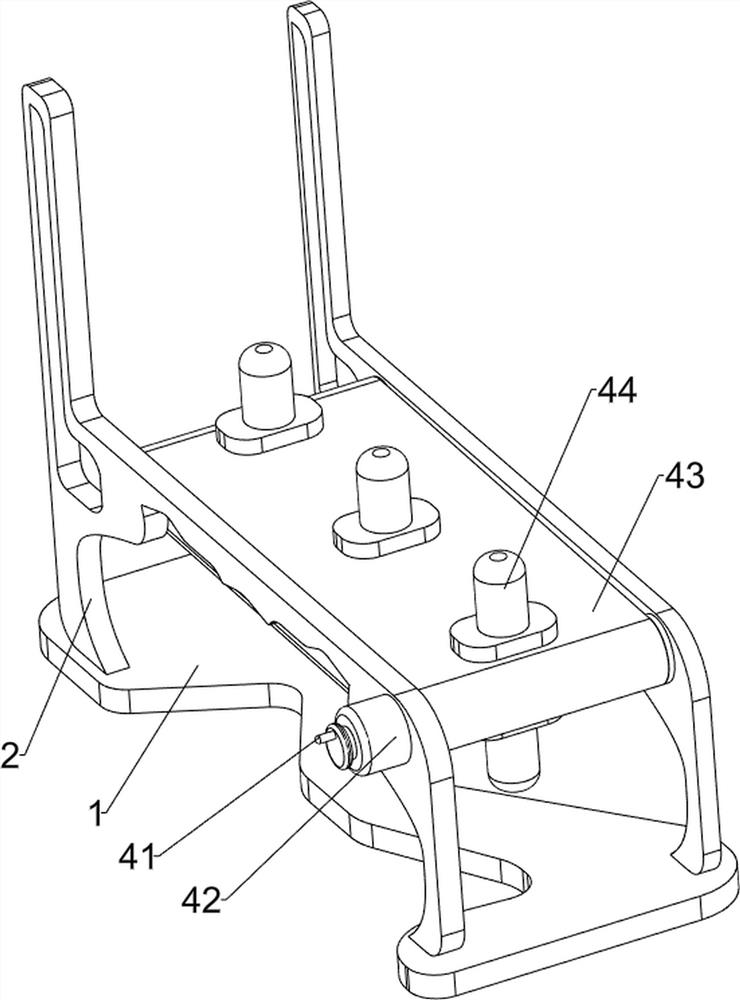

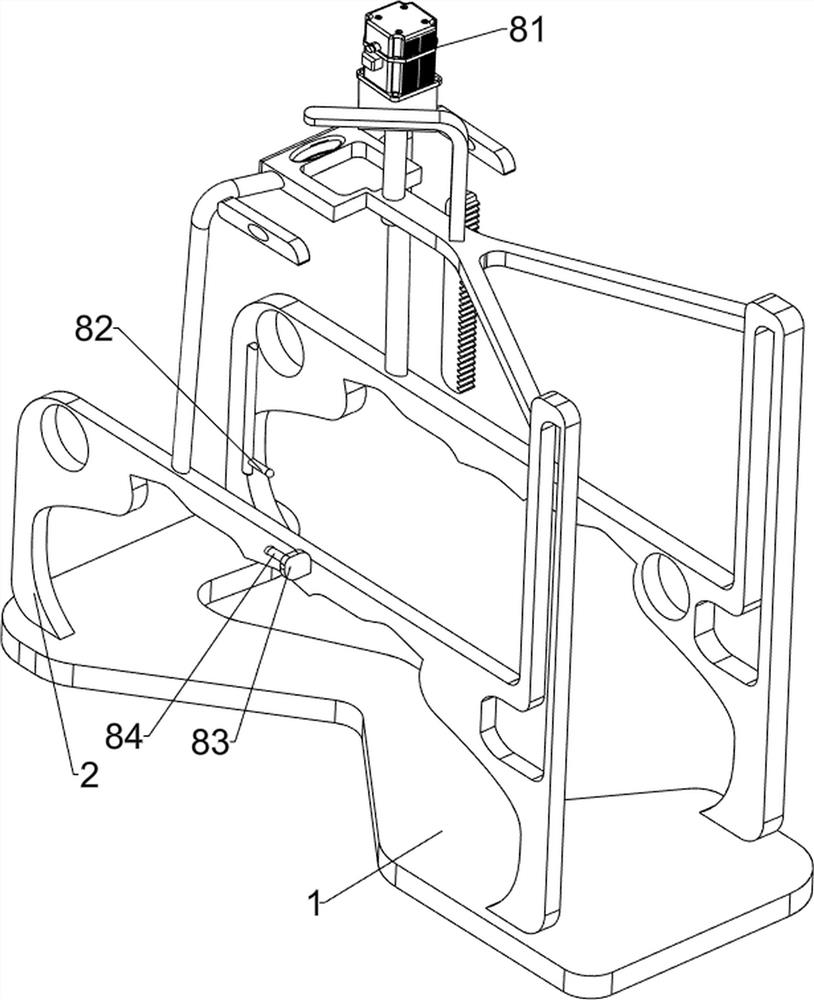

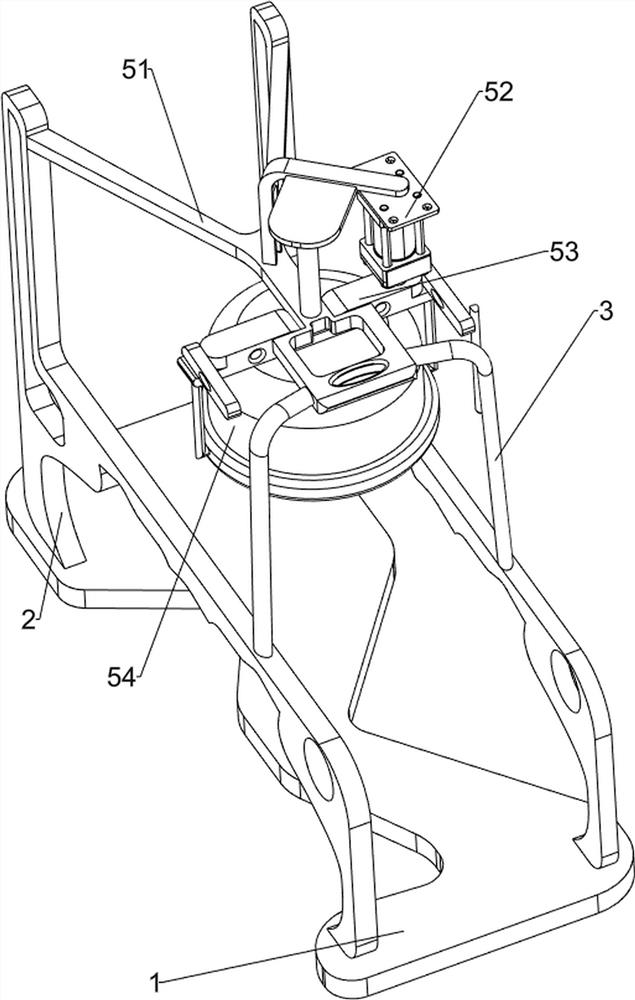

[0058] A safety helmet spray paint coloring device, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a first support 2, a first support column 3, a rotating mechanism 4 and a pressing mechanism 5. The base 1 is symmetrically provided with a first support 2, and the front side of the first support 2 is provided with a first support The support column 3 is provided with a rotating mechanism 4 on the first bracket 2 , and a pressing mechanism 5 is provided on the upper part of the rear side of the first bracket 2 and the first support column 3 .

[0059] When it is necessary to paint and color the helmet, put the helmet on the rotating mechanism 4, open the pressing mechanism 5, manually operate the rotating mechanism 4 to rotate, the rotating mechanism 4 moves to drive the helmet to move, and the pressing mechanism 5 moves downward. Move to the safety helmet, stop operating the rotating mechanism 4, people rotate the pressing mechanism 5, and the press...

Embodiment 2

[0065] On the basis of Example 1, as figure 1 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, it also includes a transmission mechanism 6. The transmission mechanism 6 includes a first connecting rod 61, a rack 62, a first rotating shaft 63, a gear 64, a transmission assembly 65 and a second rotating shaft 66. There is a first connecting rod 61, the lower side of the first connecting rod 61 is provided with a rack 62, the outer side of the first bracket 2 is provided with two first rotating shafts 63, the first rotating shaft 63 is provided with a gear 64, the rack 62 and the The gears 64 are engaged. The right side of the first bracket 2 is provided with a second rotating shaft 66 . The second rotating shaft 66 is connected with a rotating rod 41 .

[0066] When the lower pressing block 53 moves downward, it drives the first connecting rod 61 to move downward, thereby driving the rack 62 to move downward; when the lower pressing block 53 moves upward, it drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com