Automatic cutting mechanism

An automatic cutting knife technology, which is applied in metal processing and other directions, can solve the problems that the distance of the cutting knife cannot be adjusted, and the material is easy to stick to the cutting knife, so as to achieve long working hours, avoid affecting work, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

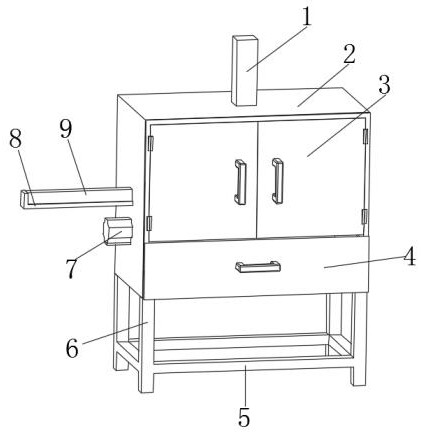

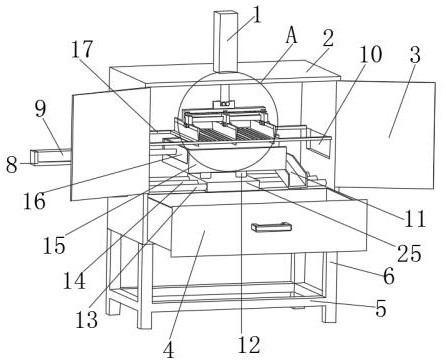

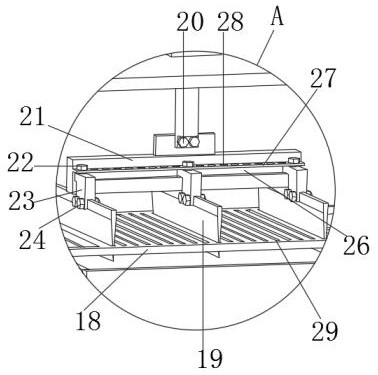

[0018] Example: see Figure 1-Figure 3 , the present invention provides an automatic material cutting mechanism, comprising a cutting box 2, the outer wall of the cutting box 2 is connected with a double door 3 through a hinge, the top of the cutting box 2 is fixedly installed with a first telescopic cylinder 1, the first telescopic cylinder 1 The output end of the output end extends to the inside of the cutting box 2, and the first mounting seat 21 is threaded through the first bolt 20. The outer wall of the first mounting seat 21 is provided with a chute 26, and the chute 26 on the outer wall of the first mounting seat 21 A plurality of second mounts 23 are installed, and the bottoms of the second mounts 23 are threadedly connected with a cutting knife 19 by second bolts 24, and the outer wall of the first mount 21 is fixedly connected to the limit plate 27 at the top of the chute 26, The limiting plate 27 is provided with a plurality of threaded holes 28 from top to bottom,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com