A sofa seat frame production equipment

A production equipment and seat frame technology, applied in the field of sofa seat frame production equipment, can solve problems such as cumbersome, time-consuming and labor-intensive, and achieve the effects of improving quality, high installation efficiency of snake springs, and preventing snake springs from falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

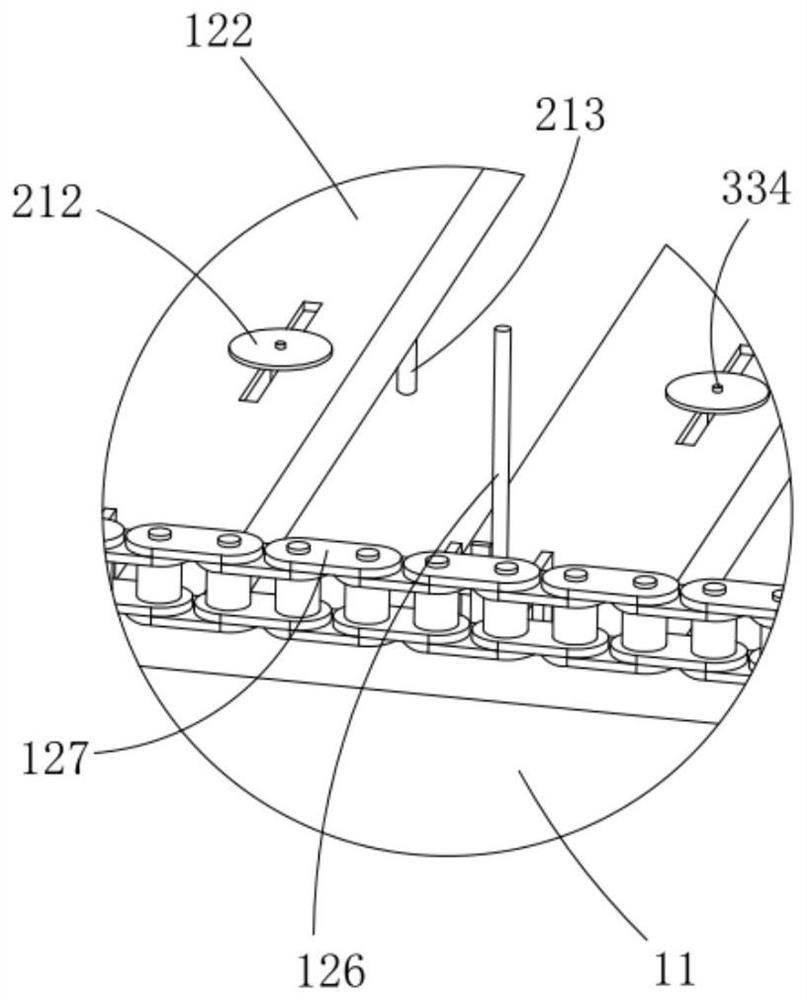

[0039] Such as Figure 1 to Figure 3 Shown, a kind of sofa seat frame production equipment comprises:

[0040]The transportation device 1, the transportation device 1 includes a mounting frame 11 and a moving assembly 12; the mounting frame 11 is rotatably arranged; several groups of the moving assembly 12 move along the path of the mounting frame 11, and the moving assembly 12 includes symmetrically arranged And the two groups of moving blocks 121 that can slide up and down and the rotating plate 122 installed between the two groups of moving blocks 121;

[0041] Fixing device 2, the fixing device 2 includes a lateral movement assembly 21 slidingly arranged on the rotating plate 122 left and right, two groups of square holes 22 opened symmetrically along the length direction of the rotating plate 122 and used for placing iron pieces, rotating The adjustment assembly 23 installed in the rotating plate 122 and can enter the corresponding square hole 22 and the pressing assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com