Monitoring device for large-scale high-grade numerical control equipment and monitoring method thereof

A monitoring device and high-end technology, applied in the field of CNC equipment maintenance, can solve problems such as dust contamination, monitoring work impact, lack of automation, etc., and achieve the effect of reducing manpower consumption and comprehensive monitoring functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

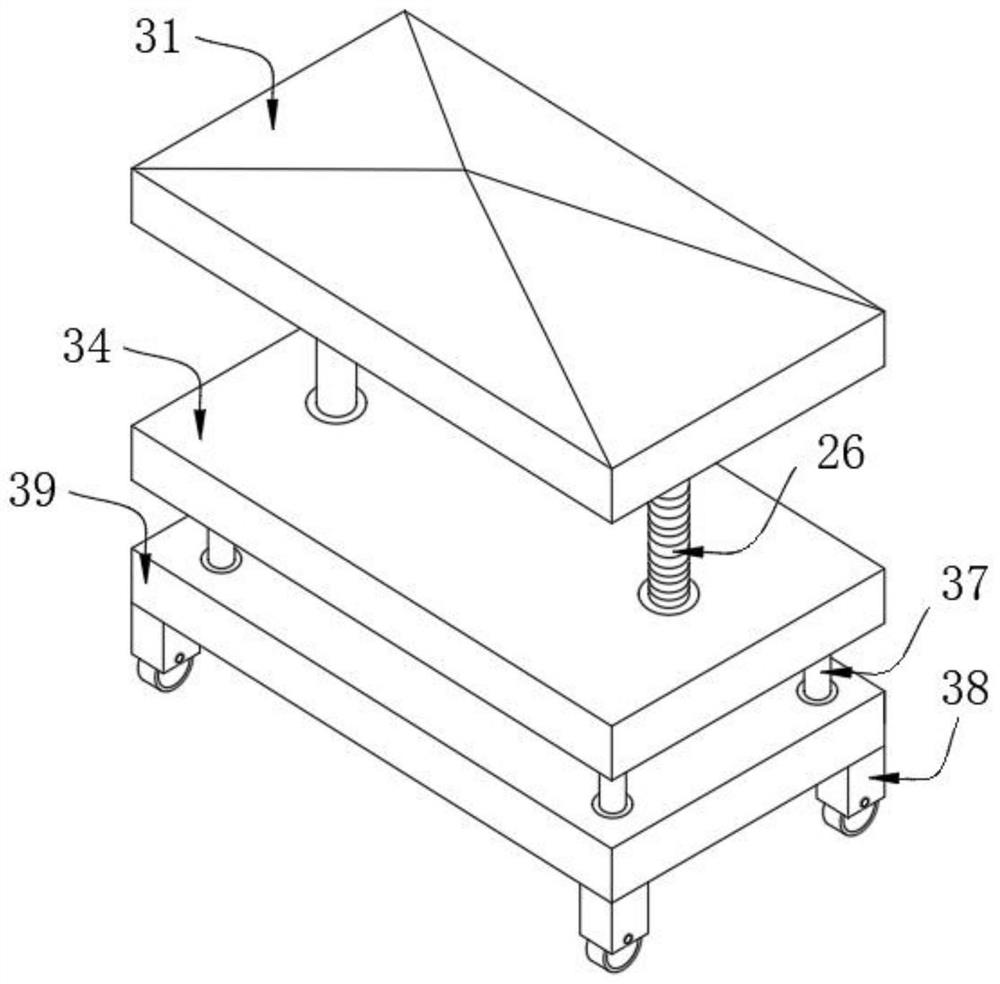

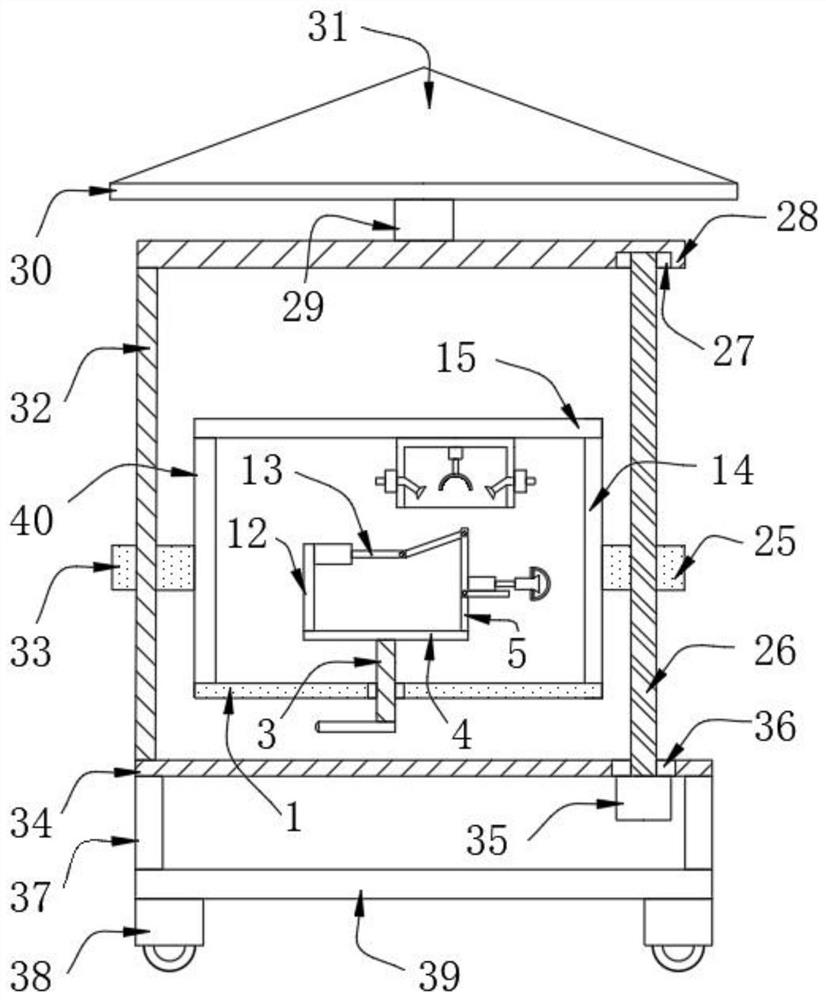

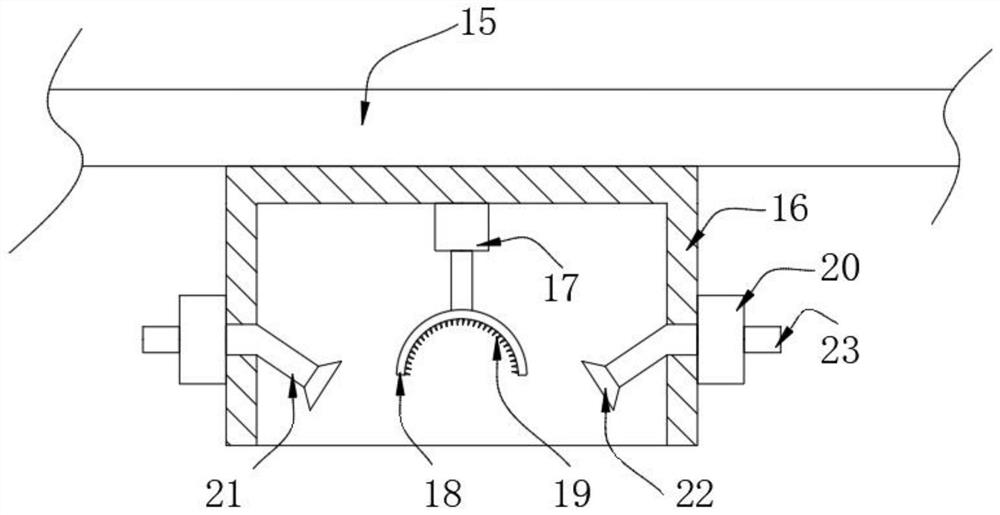

[0030] see Figure 1-5 , The present invention provides a technical solution: a monitoring device for large-scale high-end numerical control equipment, comprising a base plate 1, the interior of the base plate 1 is fixedly connected with a first bearing 2, and the inner ring of the first bearing 2 is fixedly connected with a rotating shaft 3, The top end of the rotating shaft 3 is welded with a baffle plate 4, the top of the baffle plate 4 is riveted with a vertical plate 5, the top of the vertical plate 5 is rotatably connected with an L-shaped plate 6, and one side of the L-shaped plate 6 is welded with a first cylinder 7. A camera 8 is welded to the piston rod of a cylinder 7, an annular plate 9 is threadedly connected to the outer side of the camera 8, a glass cover 10 is fixedly connected to one side of the annular plate 9, and a connecting rod 11 is rotatably connected to the other side of the L-shaped plate 6. The top of the baffle plate 4 is riveted with a support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com