Connector

A technology of connectors and contacts, applied in the direction of connection, parts of connection devices, fixed/insulated contact members, etc., can solve the problems of unusable, unreliable support and protection, and reduced reliability, so as to improve the reliability of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

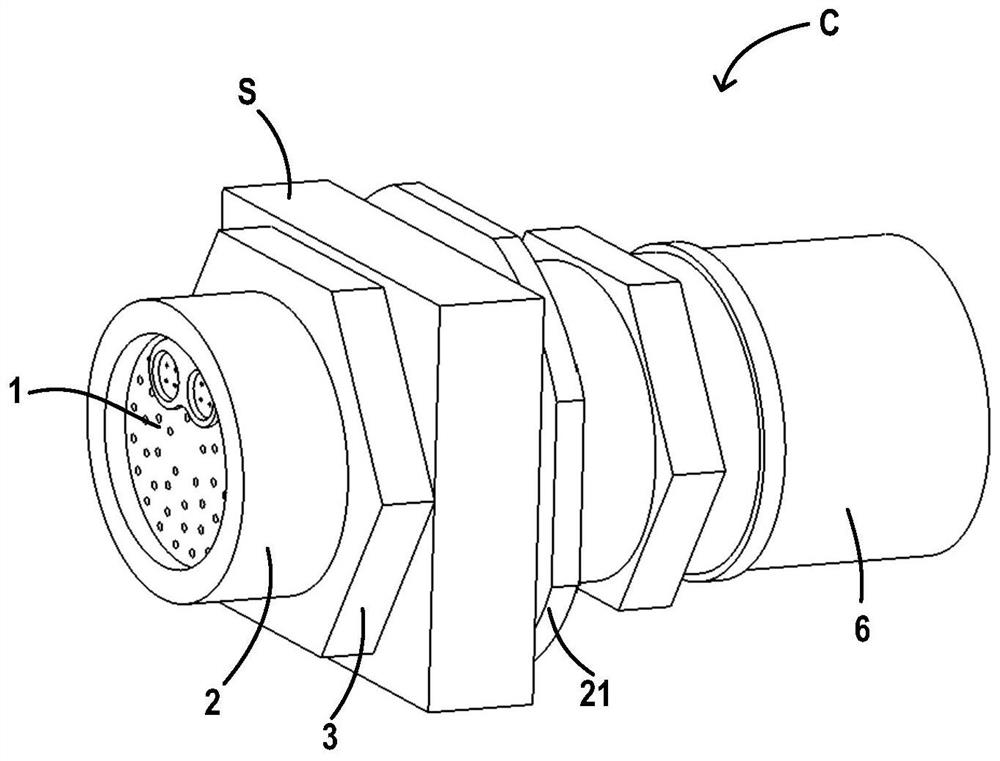

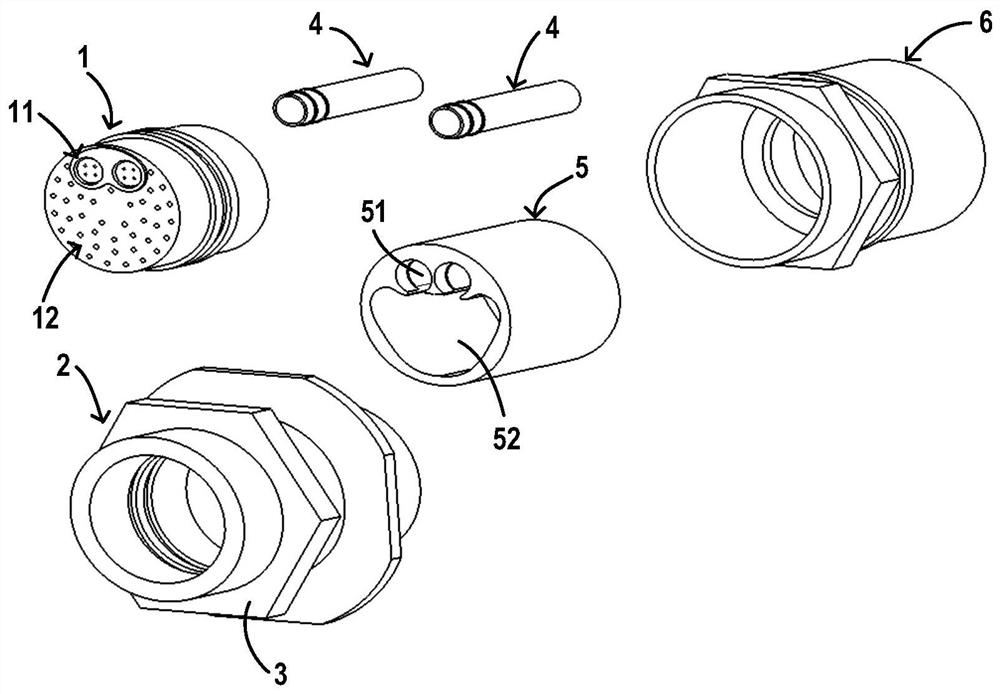

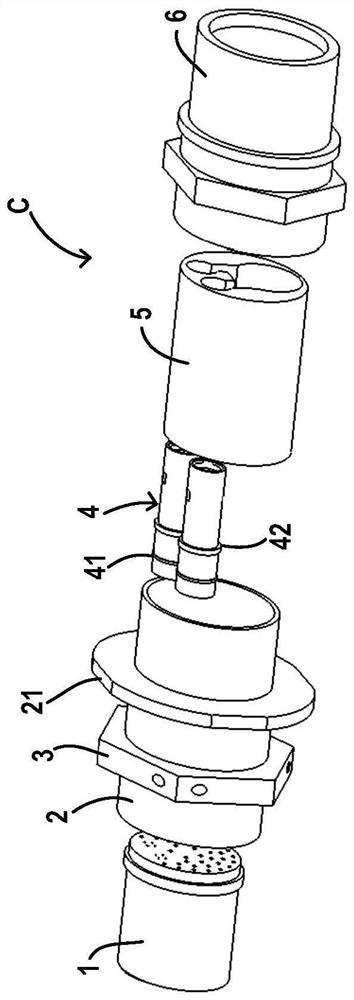

[0040] Hereinafter, embodiments of the present invention will be described in detail using the drawings. It should be noted that the parts related to the improvements of the present invention will be described in detail below, and various known structures can be adopted for other parts. In addition, the drawings are shown for convenience of description only, and some structures may be omitted from illustration or exaggerated or reduced in size compared to the actual size. In addition, in order to make the drawings clear, illustration of hatching is sometimes omitted in the cross-sectional views. In addition, in the following description, "front and rear direction" refers to the direction along the axial direction of the connector C, and the side where the connector sealing body 1 is located is referred to as "front", and the side where the connector tail wire clip 6 is located is referred to as "front". side as "rear". "up and down direction" with figure 1 The up and down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com