Self-triggering type sole dust removal equipment for dust-free workshop

A dust-free workshop, self-triggering technology, used in cleaning equipment, applications, household appliances, etc., can solve the problems of unsightly shoe covers, easy to slip, and pollute the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

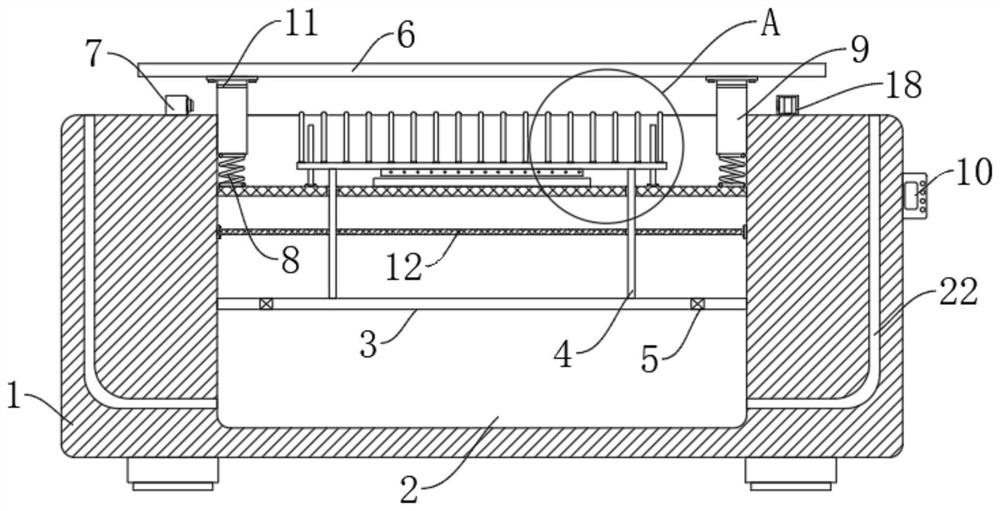

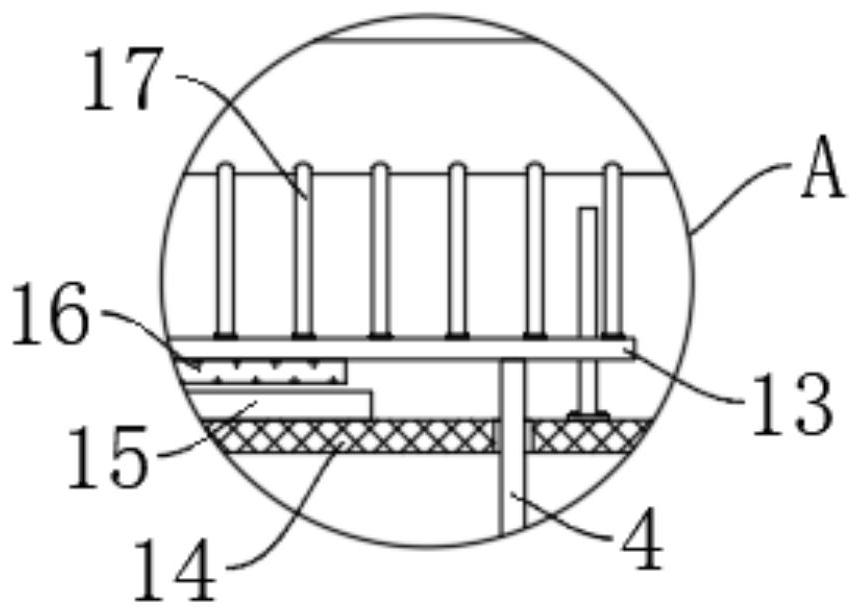

[0025] refer to Figure 1-4 , a self-triggering type dust-removing equipment for soles of dust-free workshops, comprising a casing 1, the upper end of the casing 1 is provided with a dust removal groove 2, the dust removal groove 2 is provided with a filter screen 12, and the filter screen 12 is located on the inner wall of the dust removal groove 2 Fixed connection, the dust removal slot 2 is divided into the upper trigger slot and the lower dust suction chamber by the filter screen 12, and the front side of the housing 1 is provided with a sliding door 21 for cleaning the filter screen 12;

[0026] A trigger mechanism is installed at the slot of the dust removal tank 2, and the trigger mechanism is triggered by the pressing of a person;

[0027] There is a flapping mechanism in the trigger groove, and the flapping mechanism is used for flapping the dust on the sole;

[0028] The dust suction chamber is provided with a dust suction mechanism, the dust suction mechanism coope...

Embodiment 2

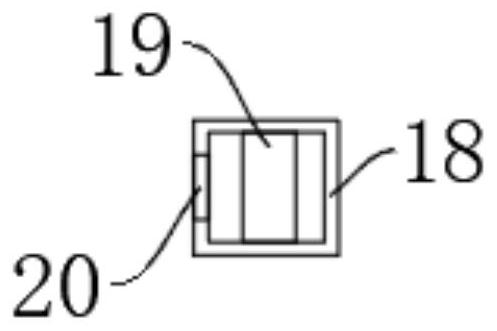

[0040] refer to Figure 5-6 The difference between this embodiment and Embodiment 1 is that the upper end of the grill plate 6 is symmetrically provided with two hollow bars 24, the opposite sides of the two hollow bars 24 are provided with a plurality of air outlets 25, and the two hollow bars 24 are provided with a plurality of air outlets 25. 24 communicates with one end of the two air outlet pipes 22 away from the bottom of the dust removal tank 2 through two hoses 23 respectively.

[0041] In this embodiment, the airflow discharged from the two air outlet pipes 22 will pass through the hoses 23, and then enter the two hollow boxes 18, and finally be discharged from the plurality of air outlets 25, and blow toward the bottom of the shoe, and the flapping mechanism In cooperation, the dust removal effect of the sole can be further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com