Automobile clutch assembling tool

A technology for assembling tooling and clutches, which is applied to manufacturing tools, workpiece clamping devices, hand-held tools, etc., can solve problems such as troublesome adjustment methods and unfavorable use by operators, and achieve the effect of improving assembly quality and expanding the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

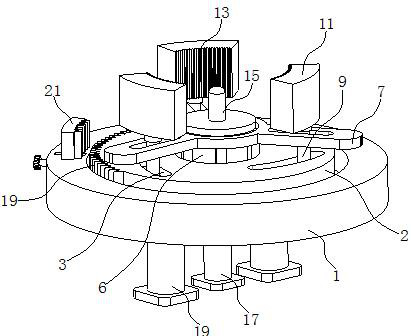

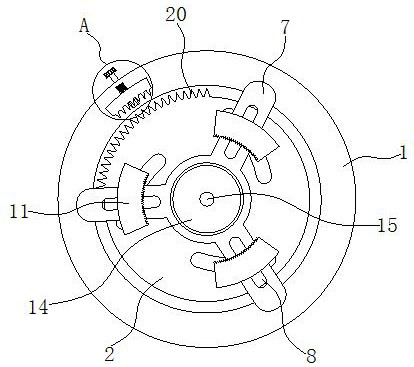

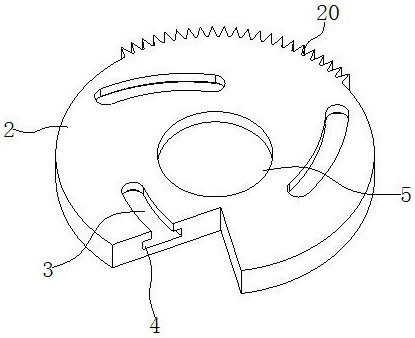

[0029] Such as Figure 1-9 As shown, the present invention provides a technical solution: automobile clutch assembly tooling, including a base 1 and a turntable 2, the top of the turntable 2 is provided with an arc-shaped chute 3, and both sides of the arc-shaped chute 3 are connected with a limit groove 4, The top of the turntable 2 is provided with a cavity 5, the inside of the base 1 is fixedly installed with a telescopic connecting plate 6, the top of the telescopic connecting plate 6 is fixedly installed with a tray 7, and the inside of the tray 7 is provided with a strip groove 8, the strip groove The inside of 8 is equipped with a push rod 9, the bottom of the push rod 9 is movably installed inside the arc chute 3, the bottom of the push rod 9 is fixedly installed with a limit block 10, and the limit block 10 is movably installed in the position of the limit groove 4. Inside, the top of the push rod 9 is movable with a clamping block 11, the inside of the clamping block...

Embodiment 2

[0032] Such as Figure 1-9 As shown, on the basis of the first embodiment, the present invention provides a technical solution: the number of telescopic connecting plates 6 is not less than two, and the distribution is evenly located inside the cavity 5 .

[0033] In this embodiment, by setting no less than two telescopic connecting plates 6, it is beneficial to stably support the tray 7, so that the tray 7 can stably support the clutch, which is beneficial to the installation of the clutch.

Embodiment 3

[0035] Such as Figure 1-9 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: there are three bar-shaped grooves 8, which are evenly distributed inside the tray 7, and the number of arc-shaped chutes 3 is three. , and evenly distributed on the top of the turntable 2.

[0036] In this embodiment, there are three clamping blocks 11. By using the three clamping blocks 11, the clutch is clamped in three different directions, which is beneficial to the stable fixation of the clutch and avoids the displacement of the clutch during the assembly process. Condition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com