Automatic labeling equipment and labeling method

An automatic and labeling technology, which is applied in the direction of labeling machines, labels, conveyor objects, etc., can solve the problems of large labeling equipment, low labeling accuracy, and complex structure, so as to optimize the labeling process and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

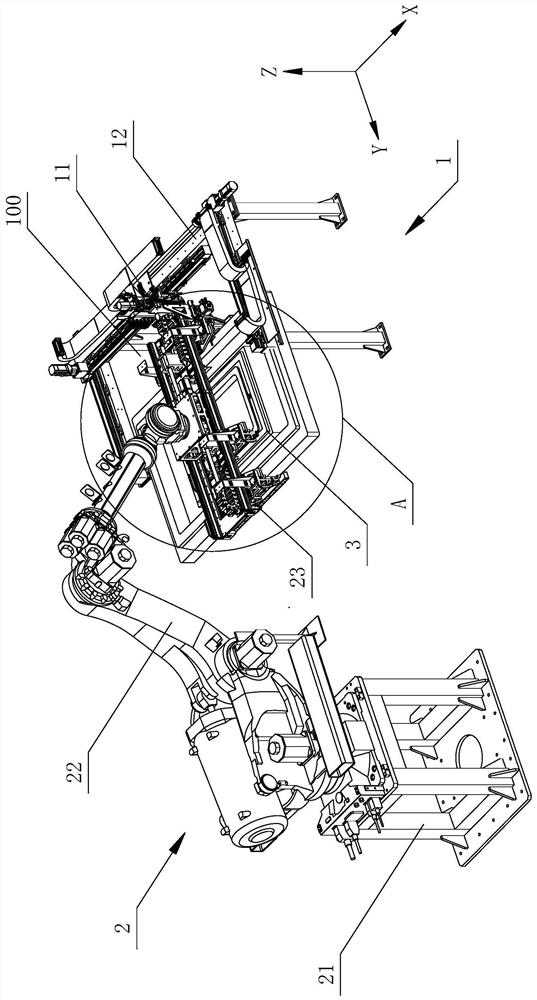

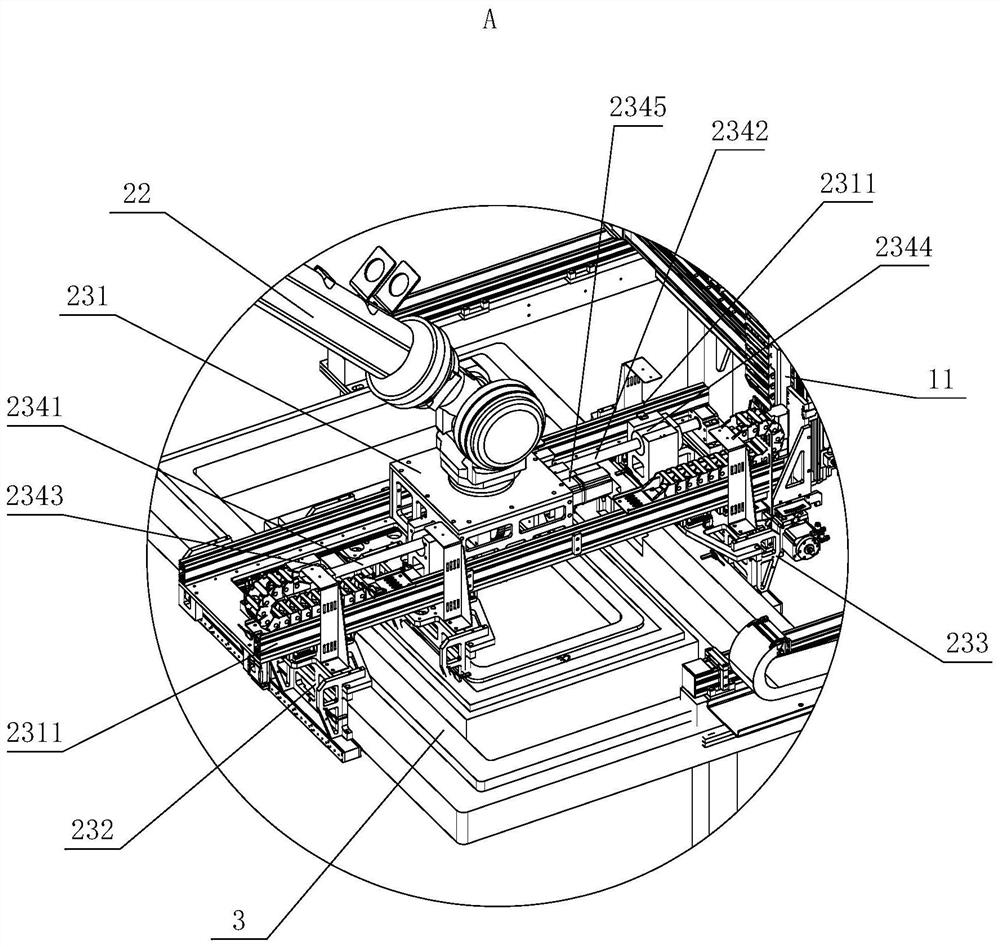

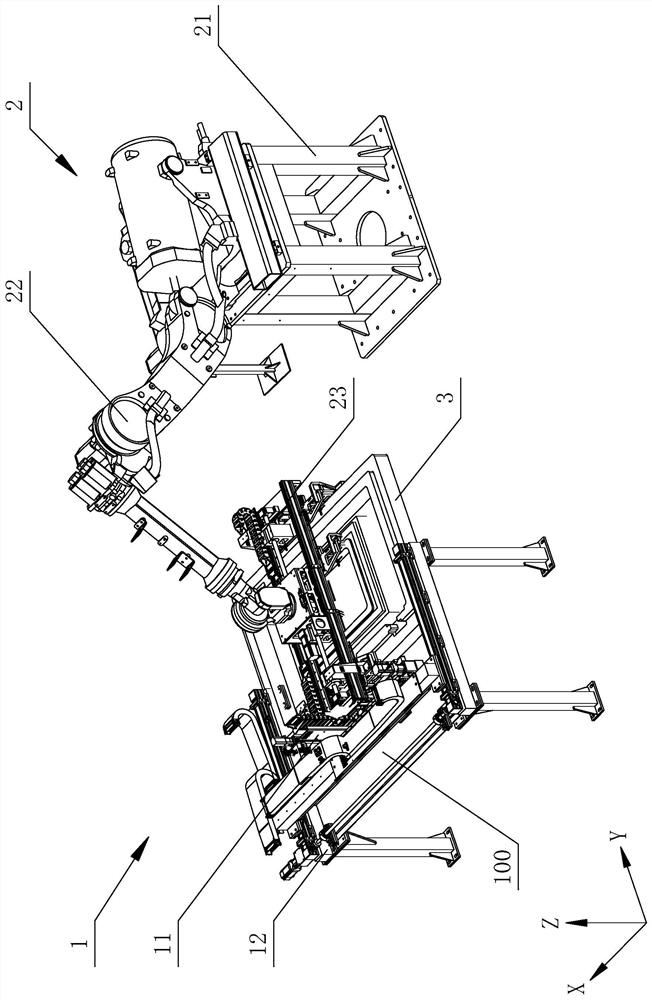

[0027] see Figure 1 to Figure 5 The shown automatic labeling equipment includes a labeling device 1 with a labeling working head 11 , and a manipulator 2 for clamping a workpiece 3 . Wherein, the labeling device 1 includes a labeling machine base 12, and the labeling working head 11 can be arranged on the labeling machine base 12 in a translational manner along the X direction, the Y direction, and the Z direction; the manipulator 2 includes a base 21, a movable arm 22 , and a clamping mechanism 23 arranged on the movable arm 22 and driven by the movable arm 22, the movable arm 22 can be set relative to the base 21 to translate in the X direction, the Y direction, and the Z direction and rotate around its own axis.

[0028] In this embodiment, the automatic labeling equipment also includes a transfer device (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com