Highway bridge safety anti-collision guardrail equipment

A technology for anti-collision guardrails and highway bridges, which is applied in bridge construction, road safety devices, bridges, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

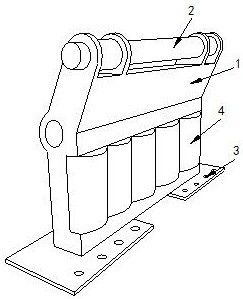

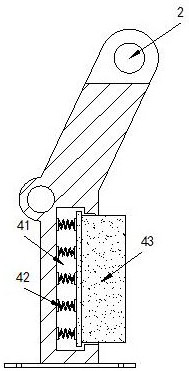

[0027] Its structure includes a main bracket 1, a protective rod 2, a fixed seat 3, and a buffer device 4. A protective rod 2 is installed on the top of the main bracket 1, and two fixed seats 3 are provided, and they are respectively welded to the bottom of the main bracket 1. At both ends of the bottom, the buffer device 4 is provided with five and arranged transversely on the front end of the main bracket 1. The buffer device 4 includes a sliding groove 41, a return spring 42, and a buffer block 43. The sliding groove 41 is arranged on the buffer device 4, five return springs 42 are installed vertically inside the sliding groove 41, and the buffer block 43 is engaged in the sliding groove 41 and is movably matched with the return spring 42.

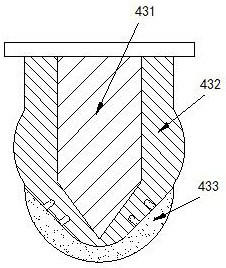

[0028] The buffer block 43 includes a support body 431, a protective layer 432, and a rubber pad 433. The outer...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033] The rubber pad 433 includes a fixed block b1, an iron sheet b2, an empty groove b3, and a friction groove b4. There are four fixed blocks b1, and the fixed block b1 is engaged with the protective layer 432. The empty groove b3 is provided with There are three, and they are arranged at the inner end of the rubber pad 433. There are six friction grooves b4, and they are arranged around the bottom of the rubber pad 433. out of shape.

[0034] The empty groove b3 includes a groove body b31, a limiting block b32, and a deformation groove b33. Six limiting blocks b32 are arranged at both ends of the groove body b31, and are arranged in groups of three horizontally on both sides of the groove body b31. end, the end faces between the limit blocks b32 are aligned, the deformation groove b33 is provided with four, and are respectively located between two li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com