Pre-bending laminated wood-concrete composite beam construction equipment

A construction equipment and glulam technology, applied in bridge construction, bridges, joists, etc., can solve the problems of stress concentration at the height of steel beam arches, fatigue damage, and lack of literature reports in the construction of glulam-concrete composite beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

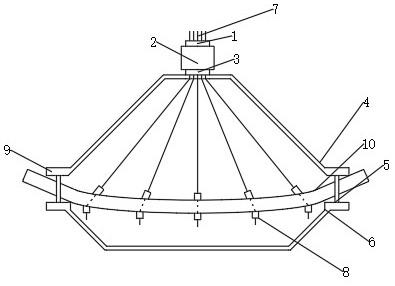

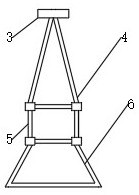

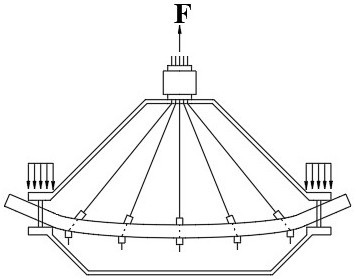

[0025] The following is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 The structure and working process of the present invention are described in detail.

[0026] A pre-bent glulam-concrete composite beam construction equipment includes a support frame for fixing a curved glulam beam. The support frame is connected by an upper support frame 4 and a lower support frame 6 through bolts 5 . Before the upper support frame is installed with the lower support frame, it is necessary to select a site with a larger area according to the design span of the composite beam, and to reinforce the foundation and drive in anchor piles, and fix the four fulcrums of the lower support frame to the foundation through anchor bolts superior. A tool anchor 1 is set on the top of the upper support frame, and several steel strands 7 for passing through the bending beam are arranged between the upper support frame and the lower support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com