Crossbow-method-based pre-bending laminated wood-concrete composite beam construction equipment

A kind of construction equipment and glulam technology, which is applied in bridge construction, bridges, joists, etc., and can solve the problems of late start of pre-bent composite girder bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

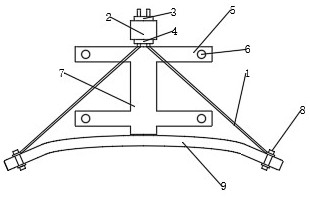

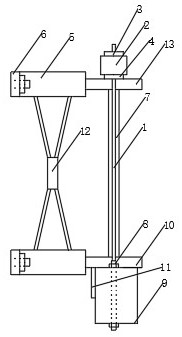

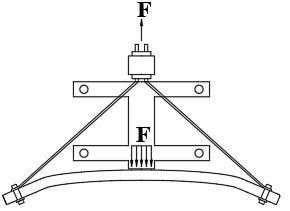

[0023] The following is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 The structure and working process of the present invention are described in detail.

[0024] For new materials, only new production equipment can be used to complete the production of composite beams. The construction equipment consists of reaction device, tool anchor, limit plate, tension steel strand, construction platform (reaction support frame, longitudinal support beam, transverse support Beams, lateral supports, mid-span reaction supports and wooden beam stabilizers), prefabricated concrete formwork (divided into two parts, A and B), and anchor bolts. Its specific structure is described in detail as follows:

[0025] A pre-bent glulam-concrete composite beam construction equipment based on the crossbow method, including tension bolts 8 respectively arranged at both ends of the curved glulam beam 9, and a longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com