Small-diameter shield well inner integral transverse moving platform

A shield well and small-diameter technology, which is applied in earth drilling, transportation and packaging, underground transportation, etc., can solve problems such as construction efficiency and achieve reasonable configuration and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

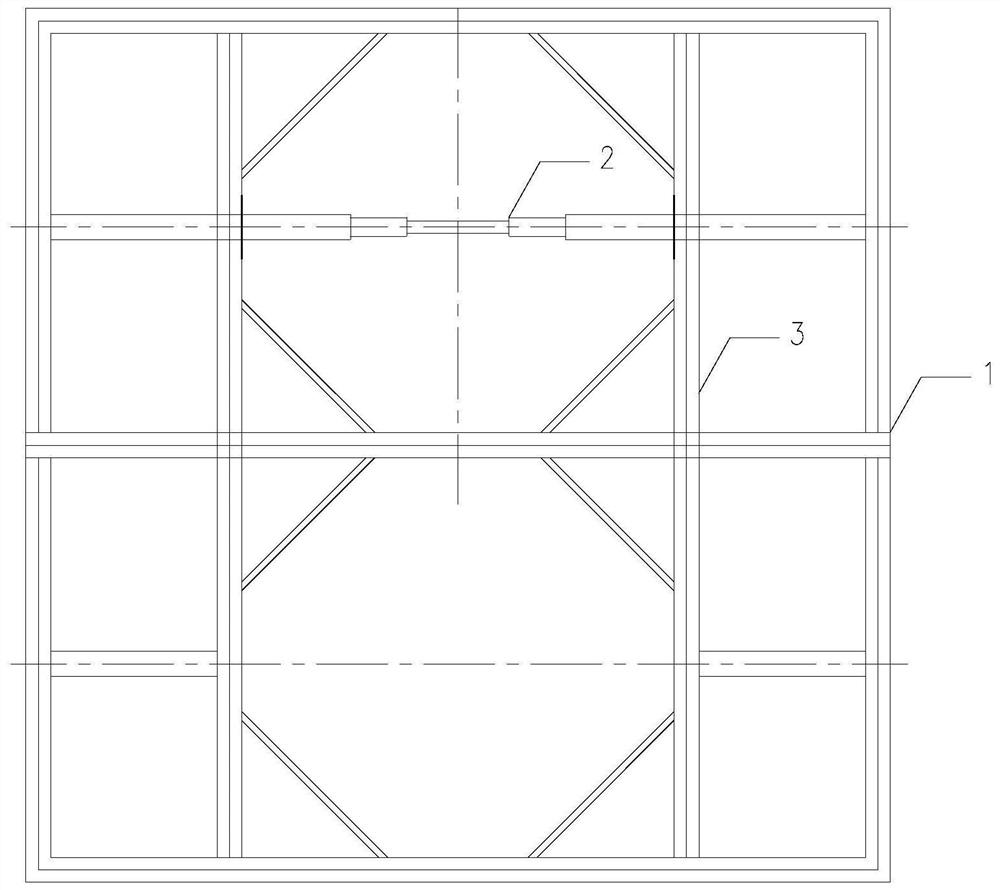

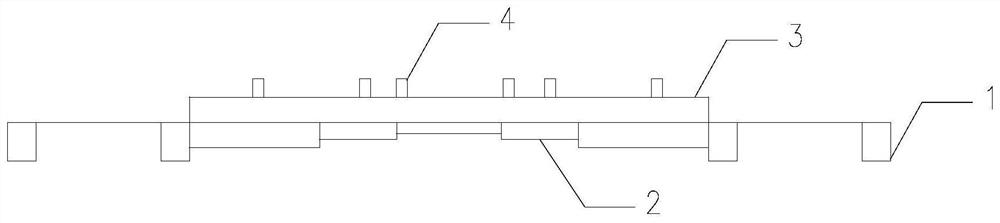

[0012] The features of the present invention and other relevant features are described in further detail below in conjunction with the accompanying drawings through the embodiments, so as to facilitate the understanding of those skilled in the art:

[0013] Such as figure 1 , as shown in 2, this embodiment specifically relates to an integral traversing platform in a small-diameter shield well, which consists of a vertical and horizontal steel beam support 1, a hydraulic jacking device 2, a traversing steel platform 3 and multiple steel guide rails 4 . The hydraulic jacking device 2 is symmetrically arranged on both sides of the hole axis, and the telescopic end of the jacking cylinder of the pressing jacking device 2 is firmly welded to the upper traversing steel platform 3, and the telescoping process can drive the platform to translate together. The hydraulic jacking device 2 can be used to make the horizontal steel platform 3 translate left and right at the entrance of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com