Basic data management system and method for three-dimensional model assembly design

A technology based on basic data and 3D models, applied in image data processing, special data processing applications, calculations, etc., can solve the problems of large assembly design workload, high error rate, and large investment of talents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] In this embodiment, the specific steps of the basic data management method for the assembly design of the three-dimensional model are illustrated by taking the tower top suspenders as an example:

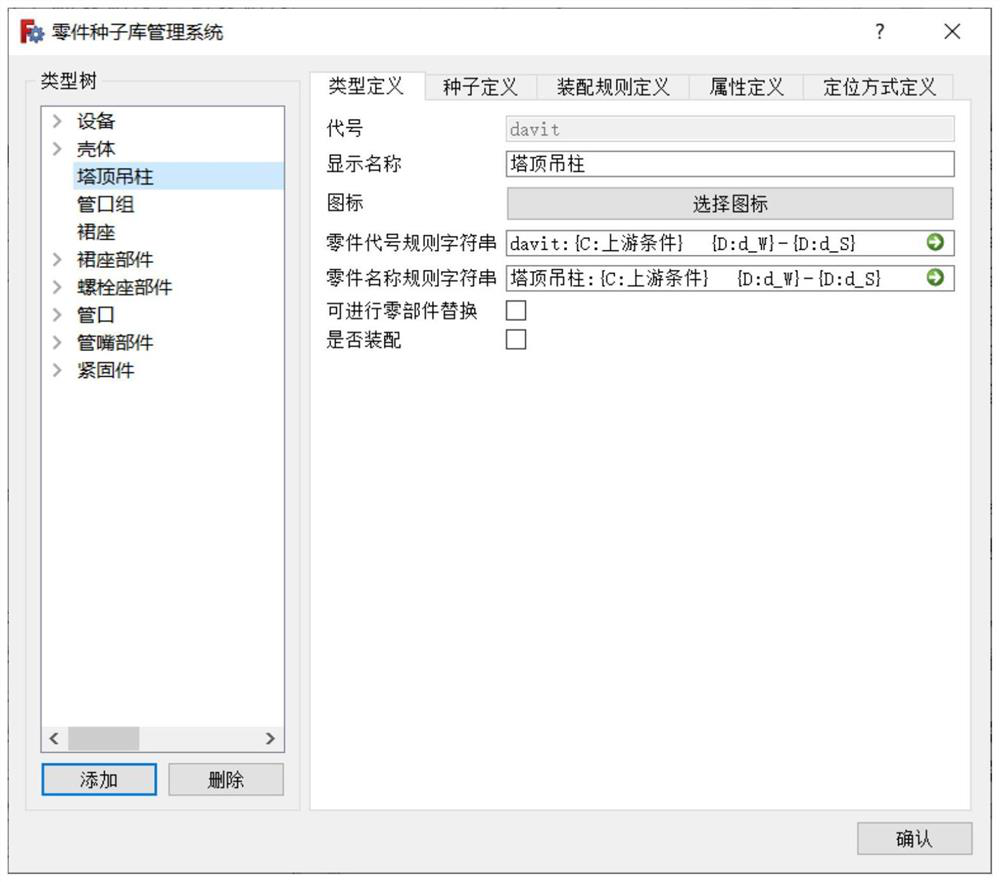

[0027] Step 1: Add the type of tower top davit in the type tree, set the name of this type as tower top davit, import a picture as the icon of tower top davit, set the rule string and other basic properties of the tower top davit; figure 1 shown.

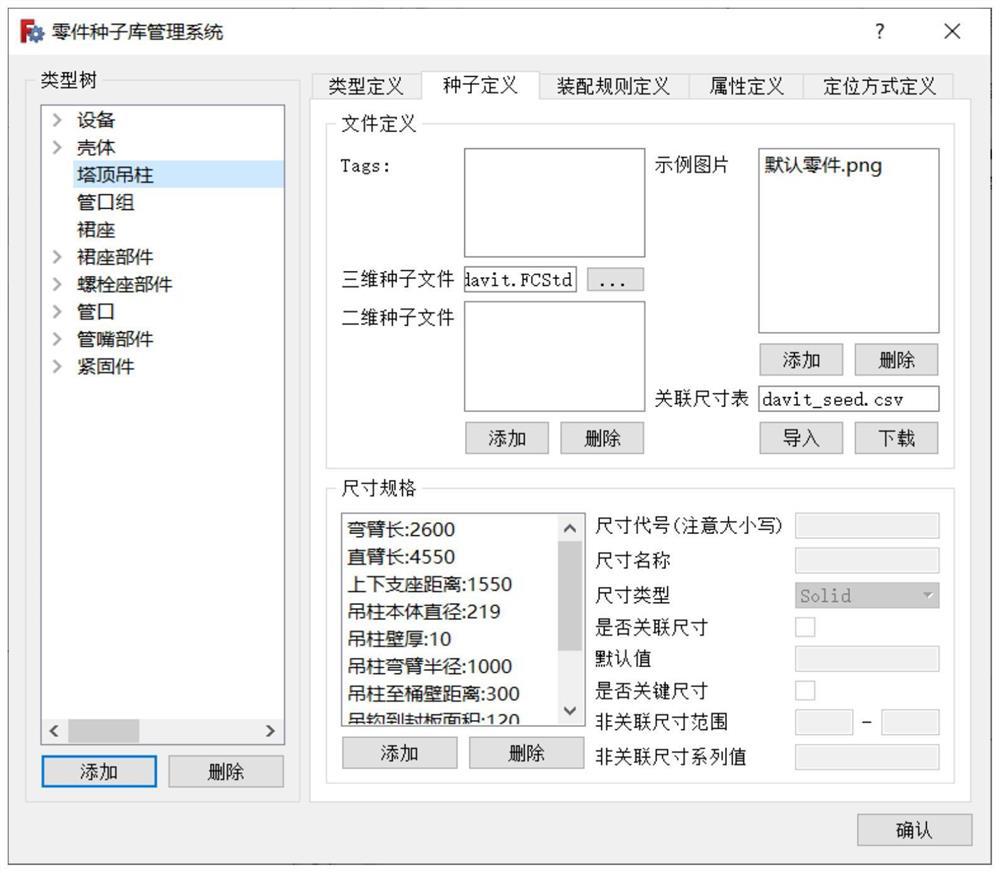

[0028] Step 2, define the seed part of the tower top davit, set its label, add an example picture, add a model file, import the associated size table, and set the size specification of the part; for example figure 2 shown.

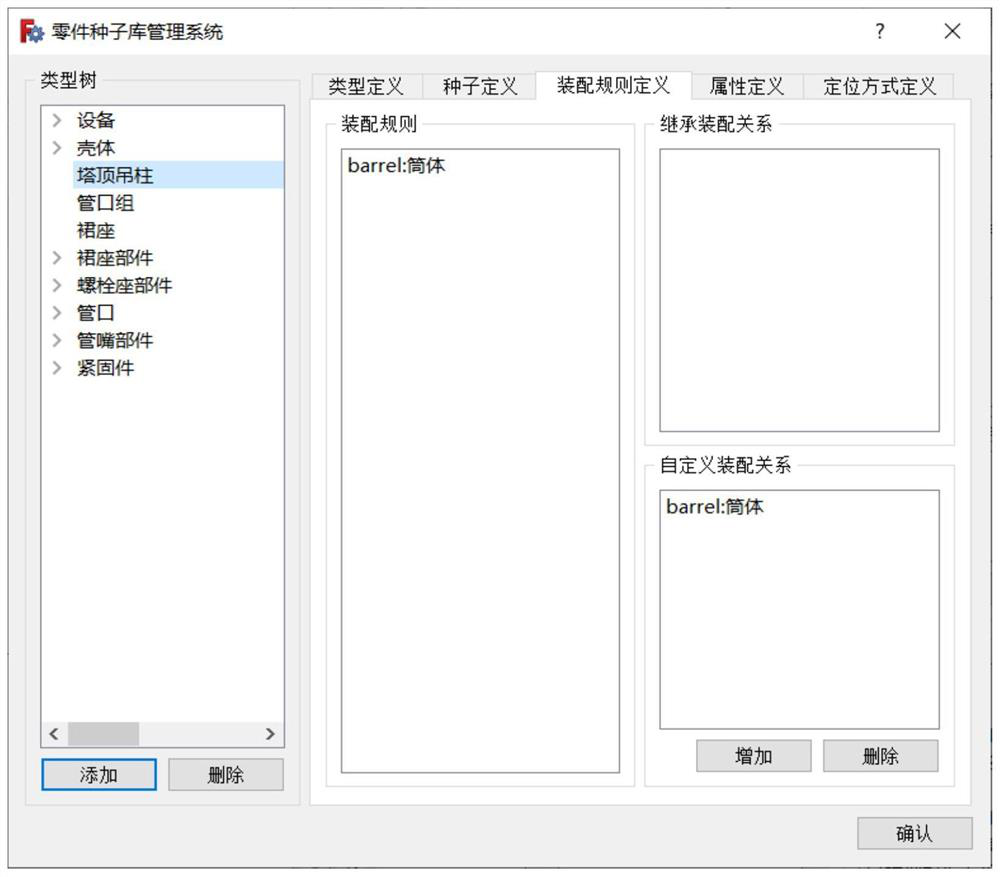

[0029] Step 3, set the assembly rules of the tower top suspenders, and add custom assembly relationships according to requirements; for example image 3 shown.

[0030] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com