Method for realizing flexible cable assembling model in virtual assembling environment

An assembly model and virtual assembly technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as difficulty in reducing production costs, difficult physical properties of cables, and inability to realize assembly simulation, etc., to achieve accurate models and interactive good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

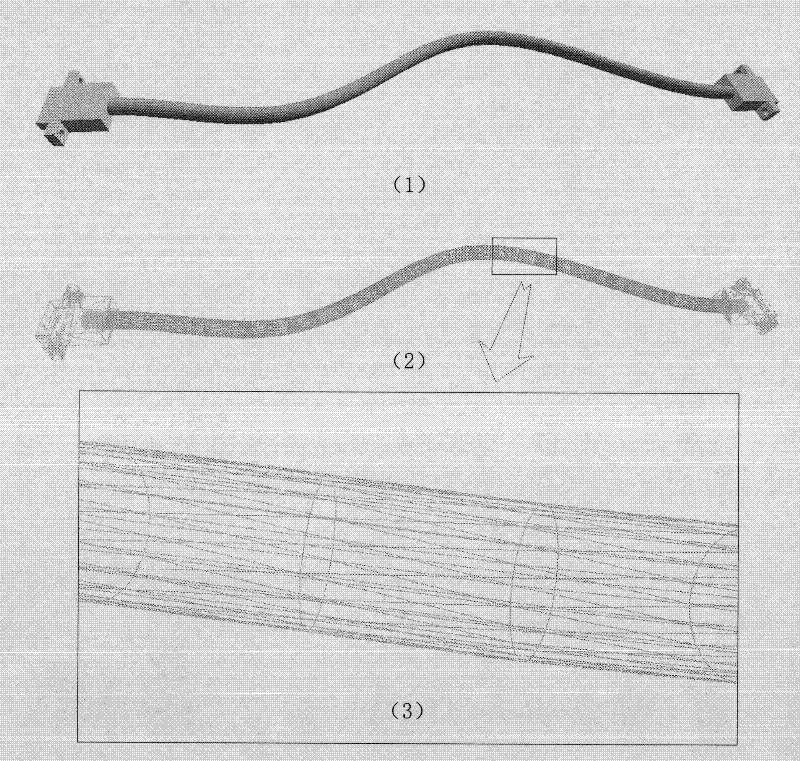

[0034] Such as Figure 1-6 shown.

[0035]A method for realizing a flexible cable assembly model in a virtual assembly environment is characterized in that it comprises the following steps:

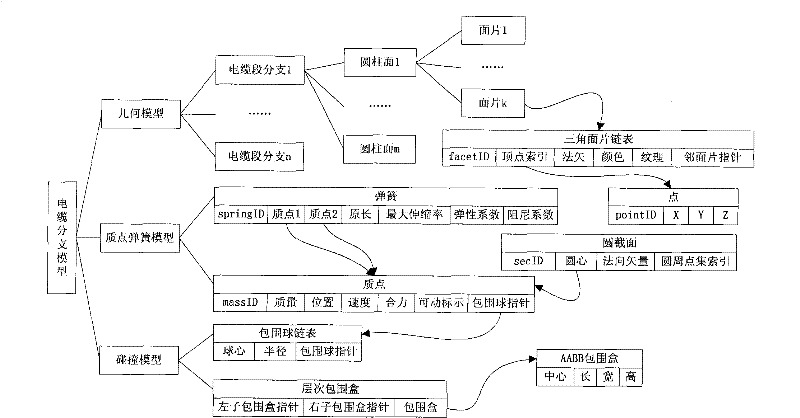

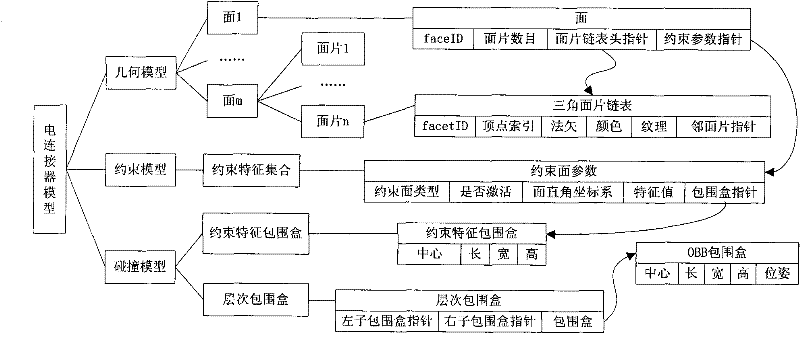

[0036] Firstly, the cable assembly model is designed for the cable wiring in the 3D CAD software, and the design information of the cable assembly model is read through the secondary development interface program of the CAD software. Then triangulate the cable assembly model to generate a neutral file in WRL format. The cable assembly model includes a cable branch model and an electrical connector model. The cable branch model in the WRL format is composed of a series of cylindrical surface connections divided by triangular faces. The connection surfaces between the cylindrical surfaces are circular sections, distributed on the circumference A series of triangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com