Cement damp caking treatment device

A processing device and agglomeration technology, applied in grain processing, solid separation, sieving, etc., can solve the problems of not being able to ensure that all the blocks are smashed, consume a lot of manpower, and have poor efficiency, so as to save loading space and save The effect of cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

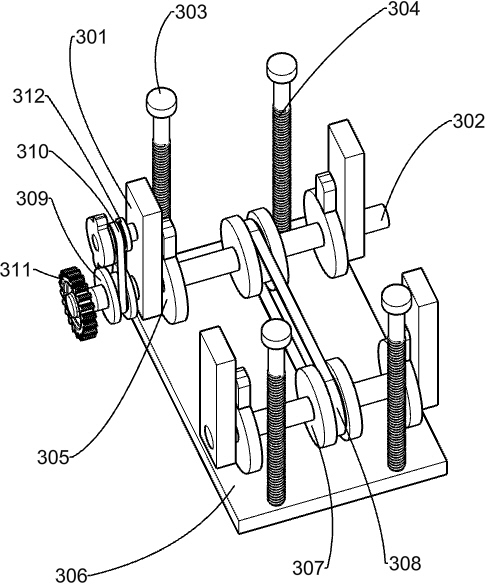

[0030] A cement damp caking treatment device, such as Figure 1-3 As shown, it includes an arc-shaped support plate 1, a first support plate 101, a second support plate 2 and an L-shaped plate 3. The lower sides of the two arc-shaped support plates 1 are arc-shaped, and the upper side of the arc-shaped support plate 1 For a smooth surface, two first support plates 101 are arranged in the middle of the two arc-shaped support plates 1, the second support plate 2 is fixedly installed on the upper end of the first support plate 101 and the arc-shaped support plate 1, and the L-shaped plate 3 is fixed Installed on the right side of the upper part of the second support plate 2, it also includes a power mechanism and a crushing mechanism, the power mechanism is fixedly installed on the second support plate 2, and the crushing mechanism is fixedly installed on the lower side of the horizontal plate of the L-shaped plate 3 , the crushing mechanism is in contact with part of the power m...

Embodiment 2

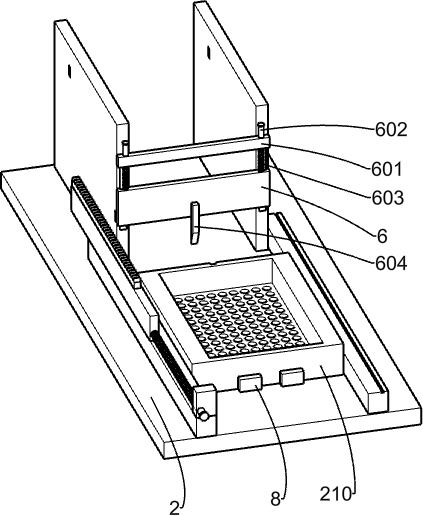

[0033] A cement damp caking treatment device, such as figure 2As shown, the power mechanism includes a support bar 201, a cylinder 202, a third support plate 203, a first support rod 204, a support block 205, a second support rod 206, a gear bar 207, a first sliding column 208, and a first spring 209 , the limit block 8 and the leaking material frame 210, two support bars 201 are fixedly installed on the left front and rear sides of the second support plate 2 top, the cylinder 202 is fixedly installed on the upper side of the support bar 201, and the two third support plates 203 Fixedly installed in the upper left middle position of the second support plate 2, two first support rods 204 are slidably installed on the front and rear sides of the upper right part of the second support plate 2, and the second support rods 206 are slidably installed on the first support On the left side of the upper part of the rod 204, the support block 205 is fixedly installed on the outer right...

Embodiment 3

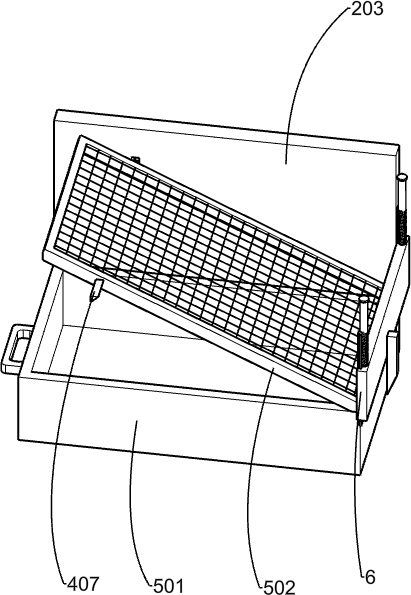

[0038] A cement damp caking treatment device, such as Figure 4-7 As shown, a screening mechanism is also included, and the screening mechanism includes a blanking frame 5, a first material box 501, a screen 502, a reciprocating mechanism and a shaking mechanism, and the reciprocating mechanism is installed at the outer middle position of the third support plate 203 , the reciprocating mechanism is in contact with the crushing mechanism, the material shaking mechanism is fixedly installed in the groove provided on the third support plate 203, the material shaking mechanism is in contact with the reciprocating mechanism, and the blanking frame 5 is fixedly installed on the upper ends of the two third support plates 203 The first material box 501 is slidably installed on the upper left side of the second support plate 2, the first material box 501 is located between the two third support plates 203, and the front and rear sides of the screen 502 are fixedly connected with the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com