NL-3A pretreatment machine cover and rear cover jig

A technology of jigs and machine covers, which is applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems that the size and flatness cannot meet the requirements of the drawings, and achieve the effect of being easy to move and fix, and convenient to carry out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

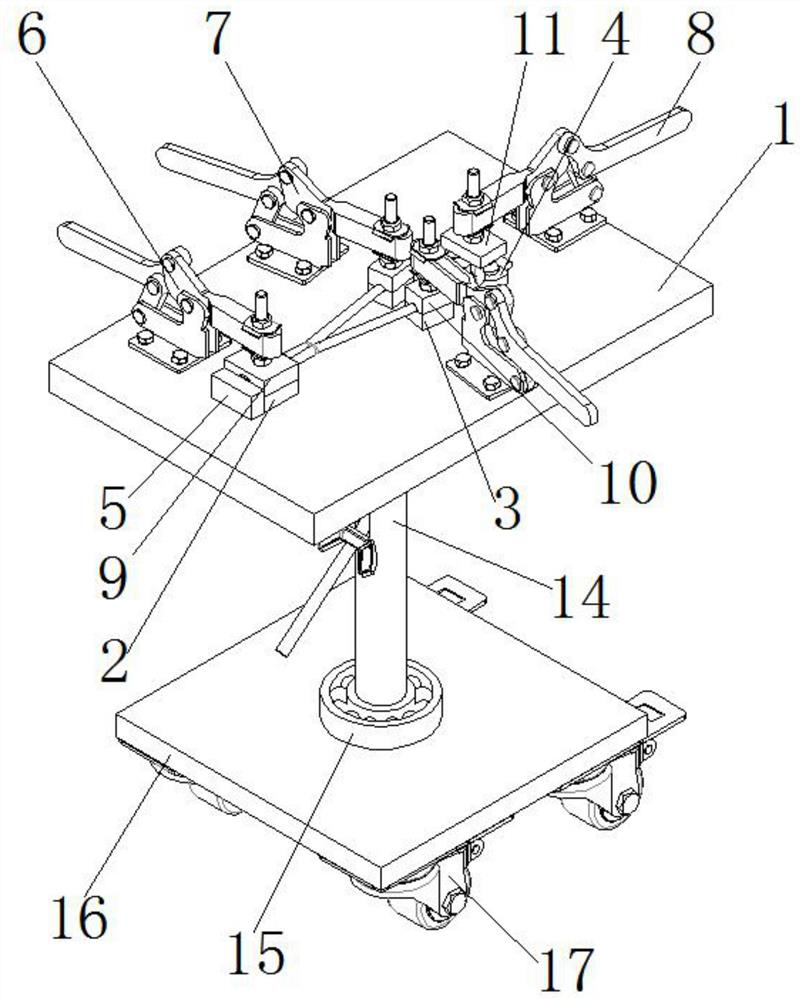

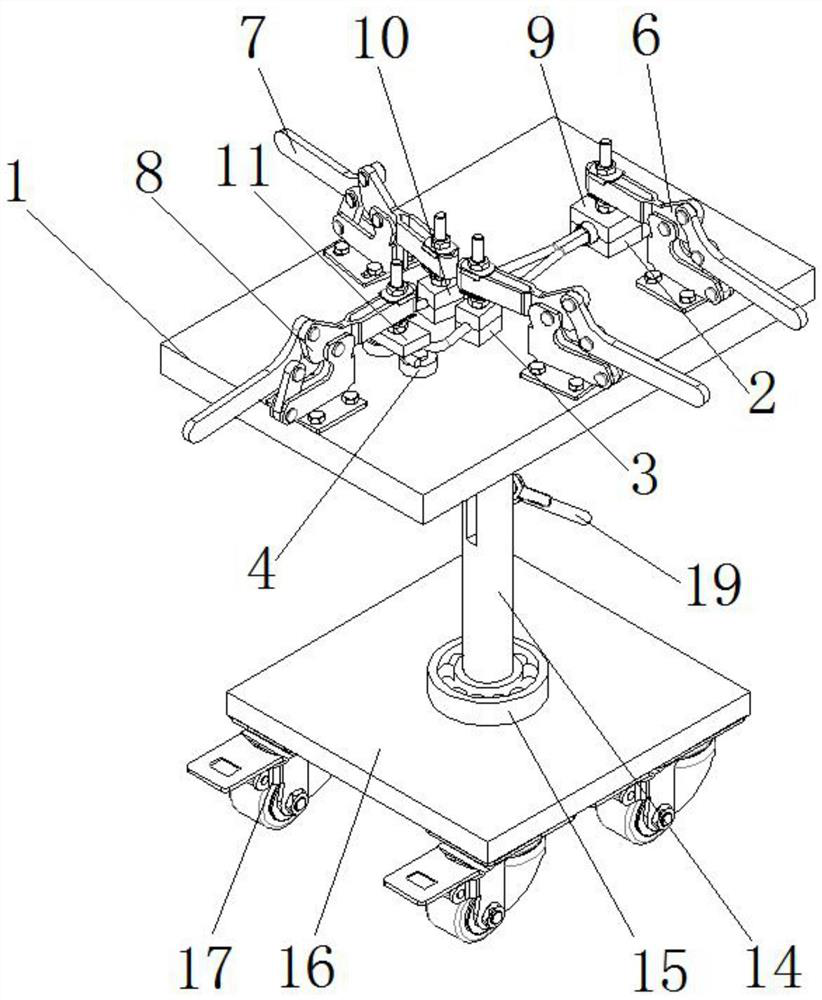

[0026] refer to Figure 4 , the lower surface of the working platform 1 is respectively fixedly connected with a rotating block 12 and a supporting block 13, the inner wall of the rotating block 12 is connected with a supporting column 14 through a rotating shaft, and the bottom end of the surface of the supporting column 14 is fixedly connected with a two-way damping bearing 15, and the two-way damping The lower surface of the bearing 15 is fixedly connected with a base plate 16, and the four corners of the lower surface of the base plate 16 are fixedly connected with universal wheels 17 with brakes. Connected with a screw 19, the front of the support column 14 is provided with a rectangular through groove, and one end of the screw 19 runs through the rectangular through groove and extends to the front of the support column 14, and the surface of the screw 19 is screwed with two butterfly nuts 20 , and two wing nuts 20 are respectively arranged on the front and back of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com