Amorphous molybdenum disulfide flexible pressure sensor and preparation method thereof

A pressure sensor, molybdenum disulfide technology, applied in the field of sensors, can solve the problems of low degree of peeling, difficulty in mass production, low output, etc., and achieve the effects of multi-scale preparation, significant resistance change, and excellent output performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

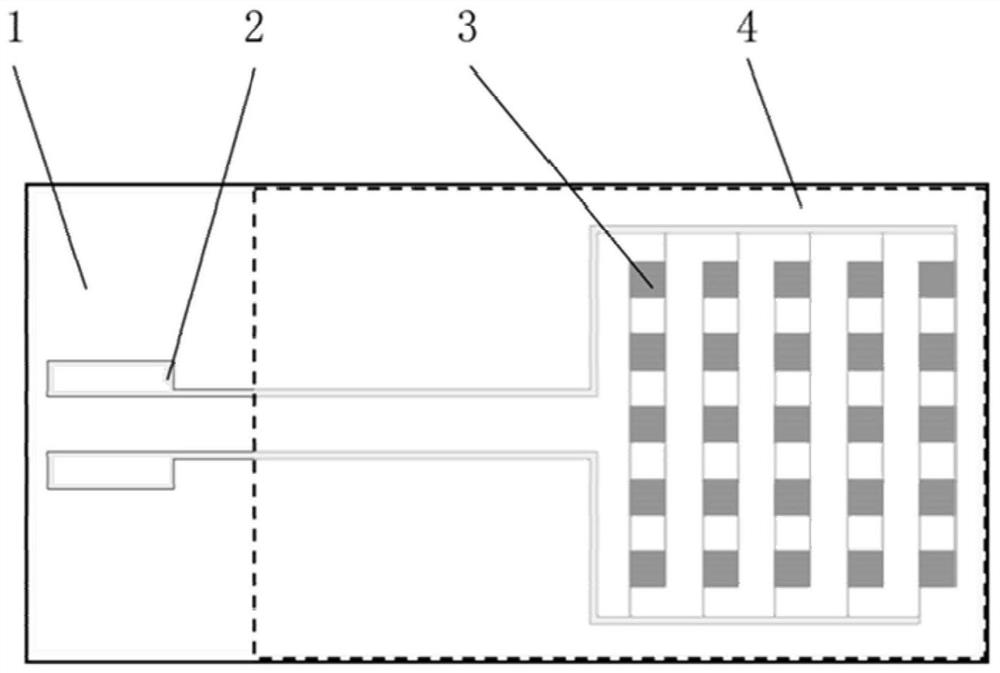

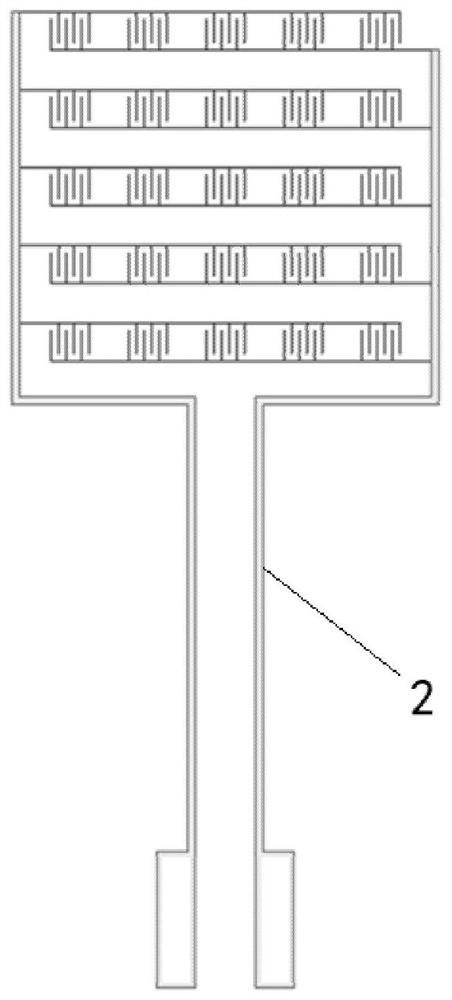

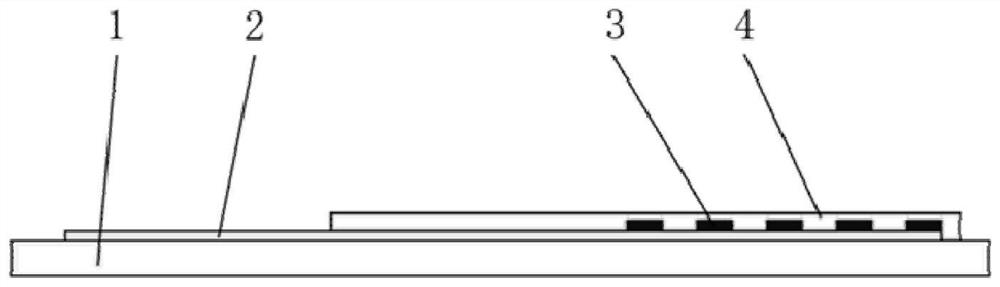

[0036] A kind of amorphous MoS of the embodiment of the present invention 2 Ultra-thin high-performance flexible pressure sensor, including: flexible substrate 1; flexible substrate 1 is sputtered with electrodes 2 and amorphous molybdenum disulfide film 3 through MEMS technology, and an organic insulating film 4 is printed on the surface of the sensitive element and electrode . Among them, the amorphous molybdenum disulfide film constitutes MoS 2 piezoresistive sensitive element.

[0037] Amorphous MoS prepared by processes such as magnetron sputtering or electron beam evaporation of the present invention 2 Ultrathin high-performance flexible pressure sensor, first discovered amorphous MoS 2 It has a good piezoresistive effect, and can realize the measurement of tiny pressure on an ultra-thin flexible substrate; the flexible function of the sensor is realized through the flexible substrate. The amorphous MoS 2 The ultra-thin and high-performance flexible pressure sensor ...

Embodiment 2

[0040] see figure 1 , the difference between the embodiment of the present invention and embodiment 1 is only that the MoS composed of the amorphous molybdenum disulfide thin film 3 2 Each unit in the piezoresistive sensitive element has a size of 1 mm×1 mm and a thickness of 1 μm. The sensitive element is an array structure, using MoS 2 The target is sputtered.

Embodiment 3

[0042] The difference between the embodiment of the present invention and embodiment 1 is that the flexible substrate 1 is made of polydimethylsiloxane (PDMS) or polyimide (PI), with a thickness of 100-500 μm. This is due to the good stretchability and flexibility of polydimethylsiloxane (PDMS), and the strong bending performance and good chemical stability of polyimide (PI). At the same time, PDMS and PI have good combination with electrons and are widely used in flexible electronics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com