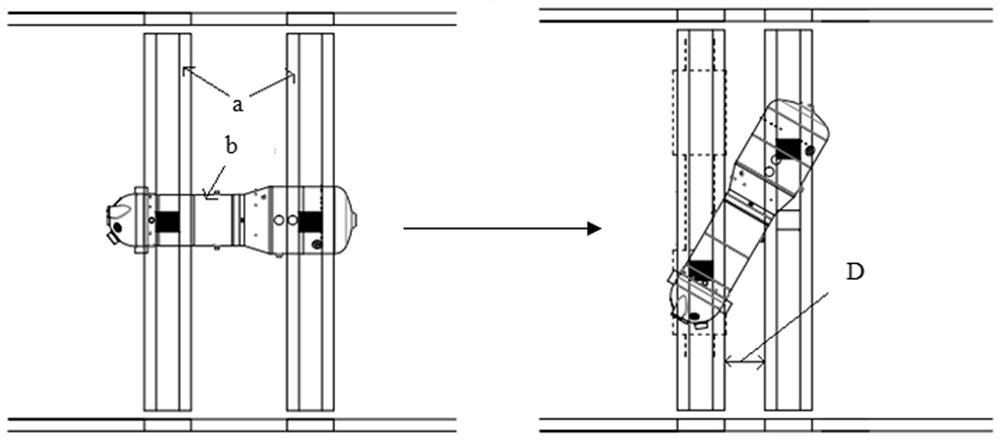

Large-scale container equipment rotation method realized by adopting large-scale container equipment rotary platform

A large-scale container and rotary platform technology, applied in the field of nuclear power, can solve the problems of high cost of hanging beams, inability to complete the rotation by driving, and inability to complete the rotation process, and achieve the effects of strong operability, simple structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

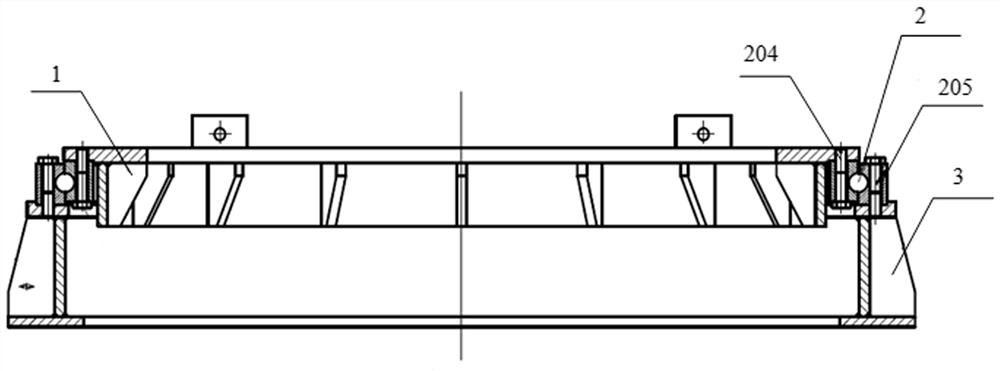

[0030] based on the following Figure 2 to Figure 9 , specifically explain the preferred embodiment of the present invention.

[0031] Such as figure 2 As shown, in one embodiment of the present invention, a large-scale container equipment rotary platform is provided, including: a turntable 1 and a turntable base 3, and a slewing support 2 respectively connecting the turntable 1 and the turntable base 3, the The slewing support 2 realizes the relative rotation between the turntable 1 and the turntable base 3 .

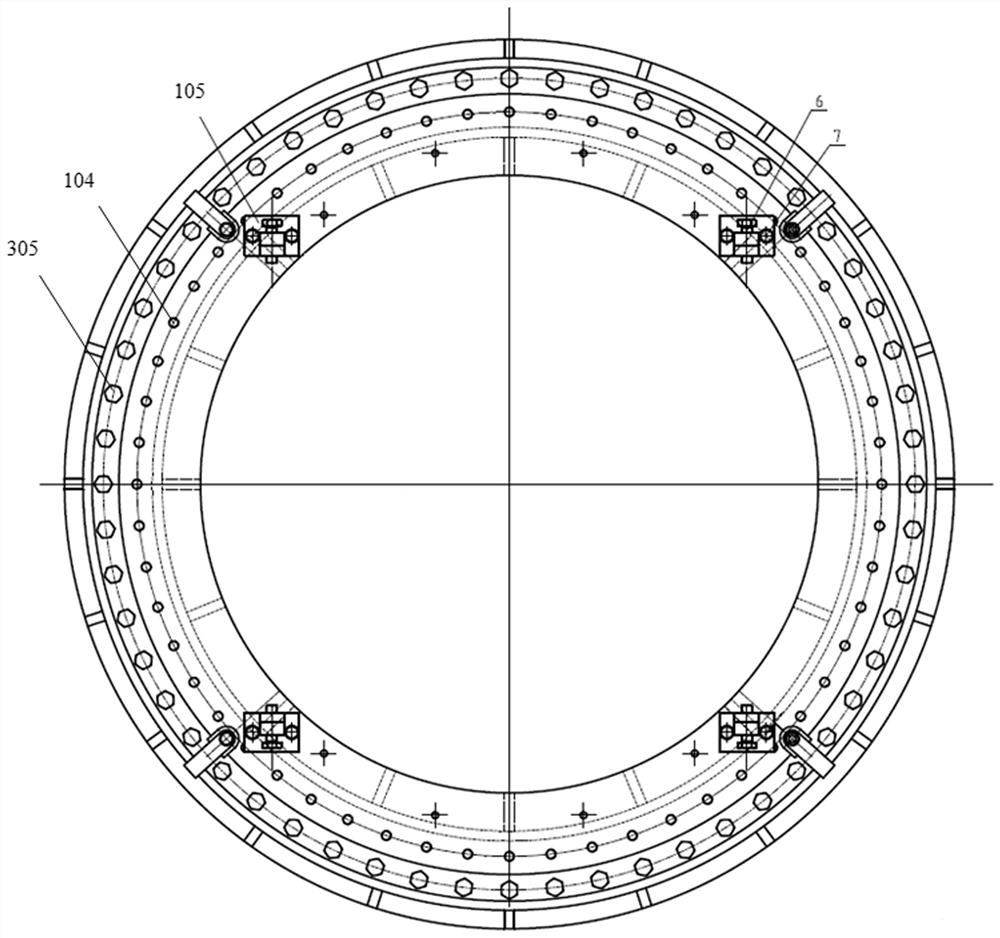

[0032] Such as image 3 and Figure 4 As shown, the turntable 1 includes: a turntable cylinder 101 , and a top ring plate 102 welded above the turntable cylinder 101 . In this embodiment, the turntable cylinder 101 and the top ring plate 102 are made of carbon steel. A plurality of first ribs 103 are arranged on the turntable 1, and the first ribs 103 are respectively connected to the turntable cylinder 101 and the top ring plate 102, and are used to enhance the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com