Frozen meat slicing machine

A technology of frozen meat slicer and slicer, which is applied in the direction of processed meat, meat processing equipment, metal processing, etc. It can solve the problems of low cutting efficiency and different sizes of meat slices, and achieve the effect of improving slicing efficiency and slicing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following is attached Figure 1-21 The application is described in further detail.

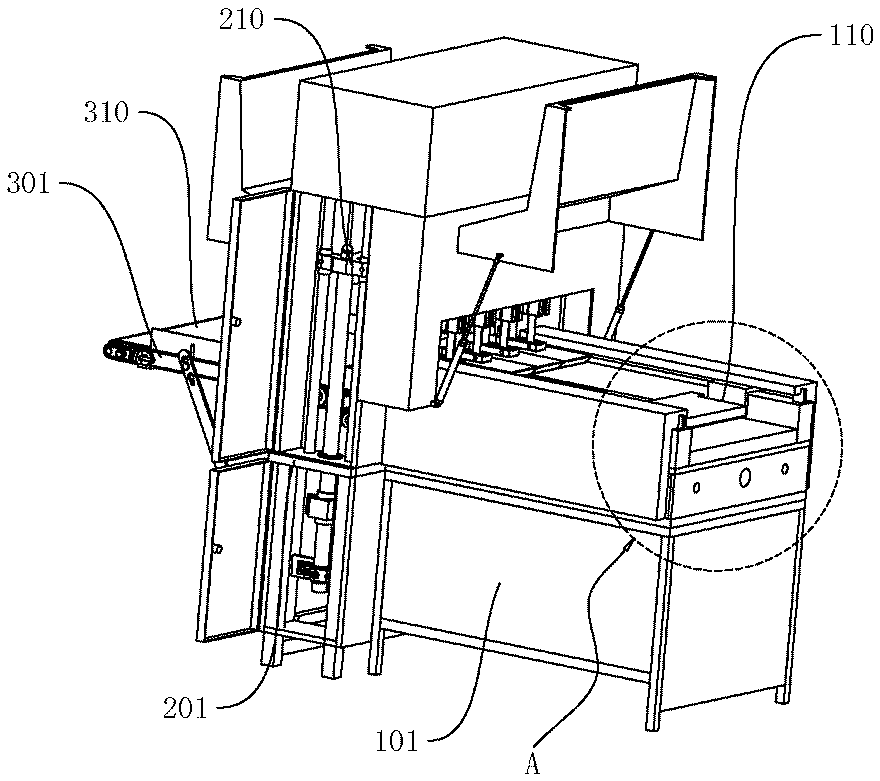

[0055] The embodiment of the present application discloses a frozen meat slicer. refer to figure 1 and figure 2 , the frozen meat slicer comprises a feed frame 101, a feed device 110 arranged on the feed frame 101, a slice frame 201 arranged on the discharge end of the feed device 110, a slice frame arranged on the slice frame 201 The slicing device 210, the discharging frame 301 arranged on the discharging end of the slicing device 210 and the discharging device 310 arranged on the discharging frame 301; , the slicing device 210 is used for cutting the frozen meat into slices, and the discharging device 310 is used for discharging and transporting the cut frozen meat slices.

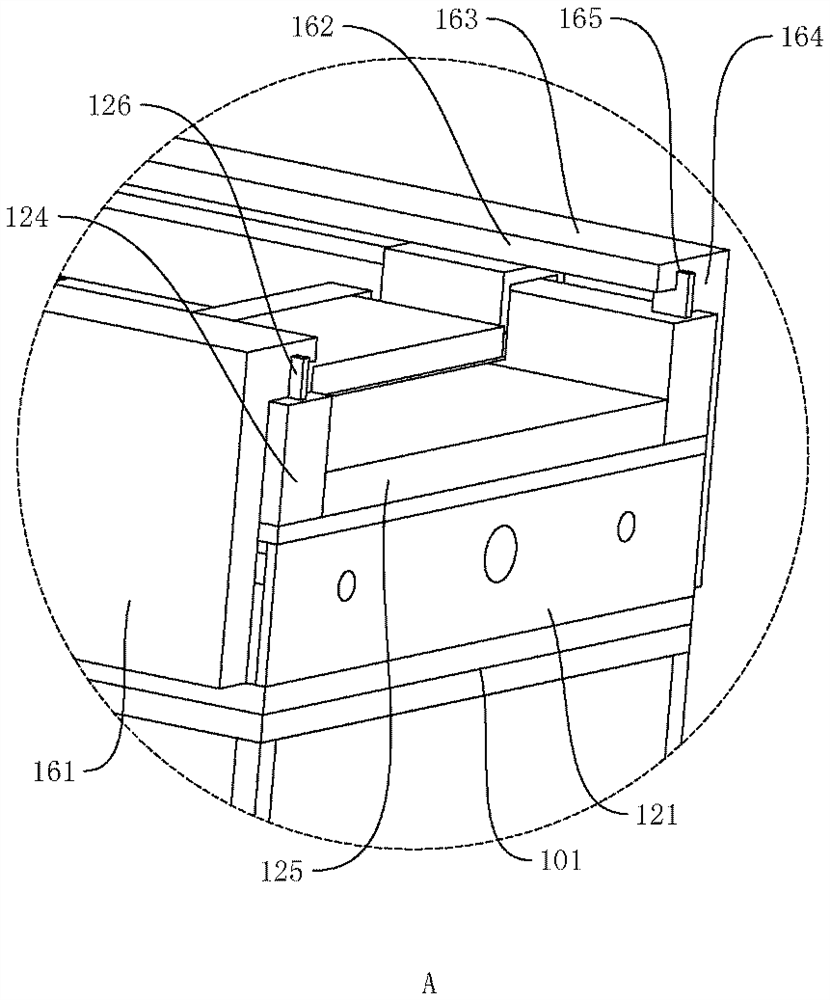

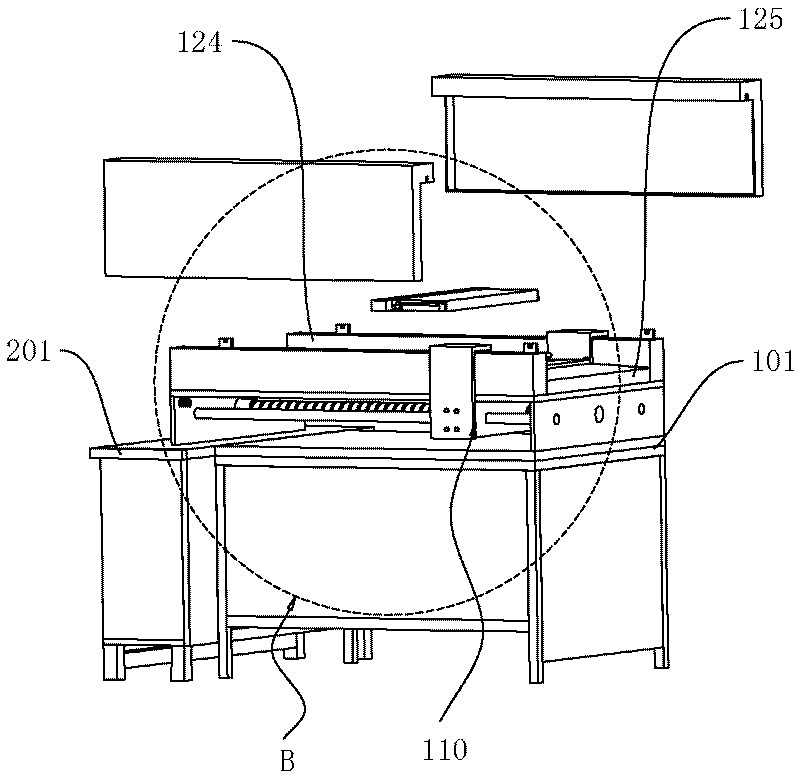

[0056] refer to image 3 and Figure 4 , the top surface of the feed frame 101 and the top surface of the slicer frame 201 are flush with each other, and the top surface of the feed frame 101 is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com