Rapid butt joint device for step forming runner

A technology of docking device and runner, applied in the field of quick docking device, can solve the problems of complex docking operation of mold runner, and achieve the effect of improving docking efficiency, reducing operation process and maintaining service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

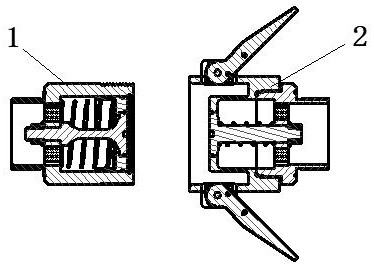

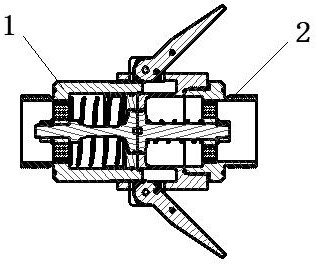

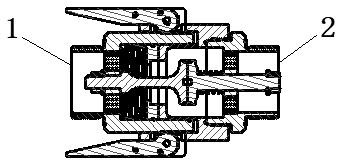

[0045]Referring to Fig. 1 to Fig. 6(D), a step forming runner quick docking device includes a male joint assembly 1 and a female joint assembly 2; the first end of the male joint assembly 1 is docked with the first end of the female joint assembly 2, The second end of the male joint assembly 1 and the second end of the female joint assembly 2 are connected to the water source or the flow channel of the mould;

[0046] Such as figure 2 As shown, the male connector assembly 1 includes a male connector body 11, a first movable core 12, a first stop core 13, a first filter screen 14 and a first elastic member 15; the first filter screen 14 is arranged on the male connector body 11, the first filter screen 14 divides the hollow cavity of the male joint body 11 into a first cavity 111 and a second cavity 112, and the first stop core 13 is arranged on the first side along the axial direction of the male joint body 11. In the cavity 111, the first end of the first stopper core 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com