Double-rubber bushing

A rubber and bushing technology, applied in the field of bushings, can solve the problems of long length of high damping rubber main spring, affecting service life, and easy to be damaged, so as to improve fatigue performance, save practical use, and increase service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

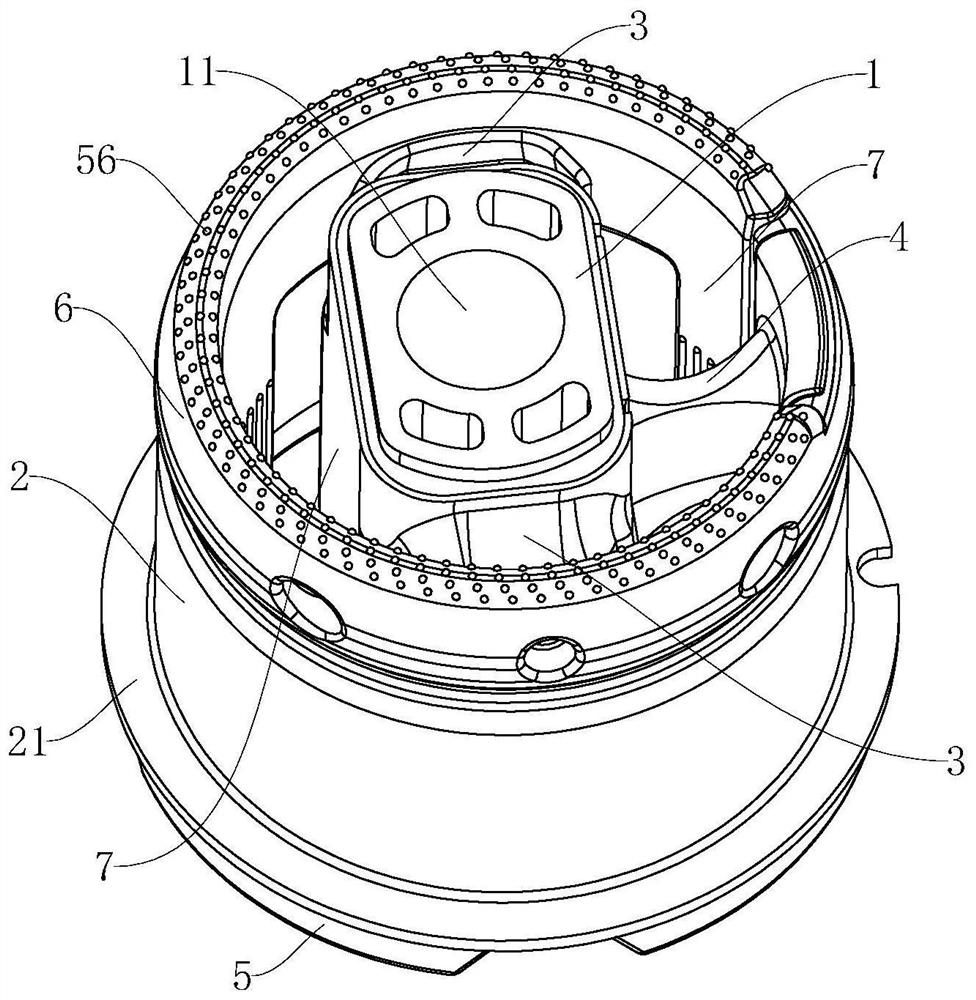

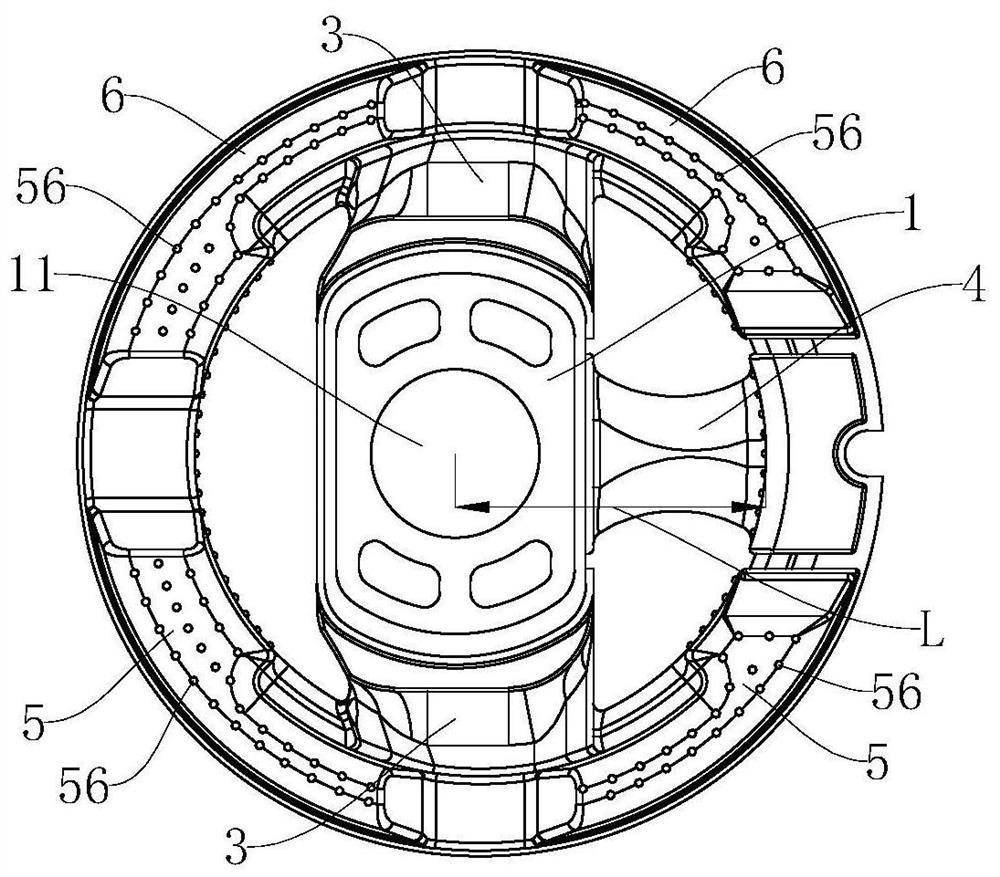

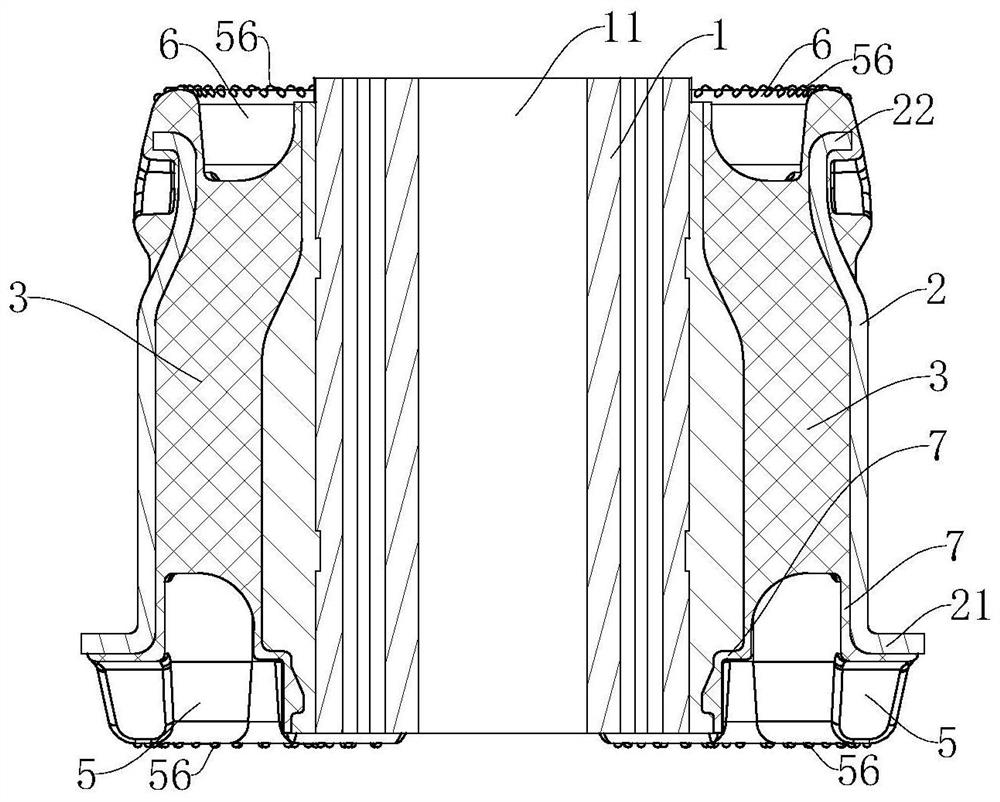

[0028] Embodiment one: if Figure 1 to Figure 4 As shown, a double-rubber bushing includes an inner tube 1 and an outer tube 2, the inner tube 1 is arranged inside the outer tube 2, and the center of the inner tube 1 is provided with a mounting hole 11 that penetrates up and down, and the inner tube 1 and the outer tube 2 A first rubber main spring is arranged between them, and the first rubber main spring is composed of two equal-length and symmetrically arranged first rubber bodies 3 on both sides of the inner tube 1. The two ends of the first rubber body 3 are respectively connected to the inner tube 1 The outer wall of the outer tube is connected to the inner wall of the outer tube 2, and a second rubber body 4 is arranged between the inner tube 1 and the outer tube 2, and the second rubber body 4 is arranged in the direction of preload and pressure, and the two ends of the second rubber body 4 The second rubber body 4 is perpendicular to the first rubber main spring, and ...

Embodiment 2

[0036] Embodiment two: if Figure 5 to Figure 8 As shown, the other parts are the same as the first embodiment, the difference is that the lower part of the inner tube 1 protrudes downwards from the outer tube 2 to form a protruding part 12, and a limit block 8 is arranged between the protruding part 12 and the lower rubber bumper 5 . The limiting block 8 can limit the radial movement of the outer tube 2 on the one hand, provide non-linear rigidity in the radial direction on the other hand, and play the role of shock absorption and buffering to improve comfort.

[0037] In this specific embodiment, the limiting block 8 has an installation through hole 81 that penetrates up and down and matches the extension part 12. The outer wall of the extension part 12 is covered with a rubber protective layer 9, and the inner wall of the installation through hole 81 Two positioning convex buckles 82 are arranged on the top, and the two positioning convex buckles 82 are arranged oppositely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com