Clamp spring pressure detection tool

A tooling and card checking technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of poor stability and low accuracy, and achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

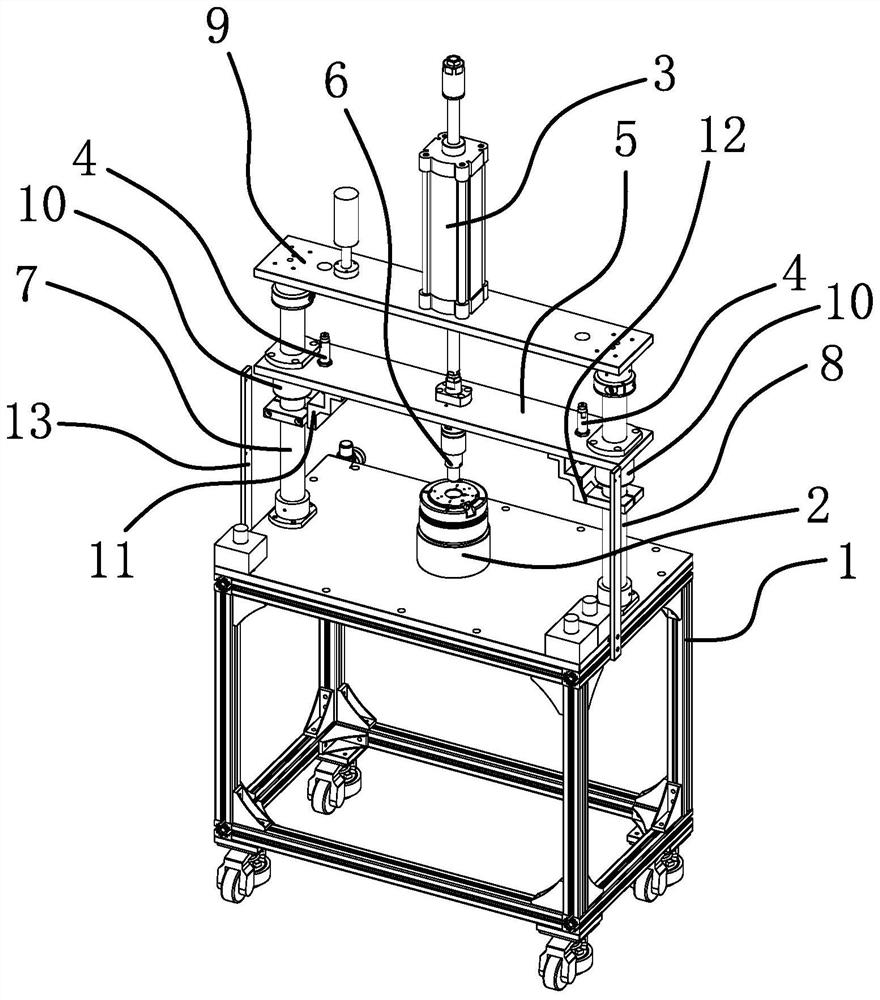

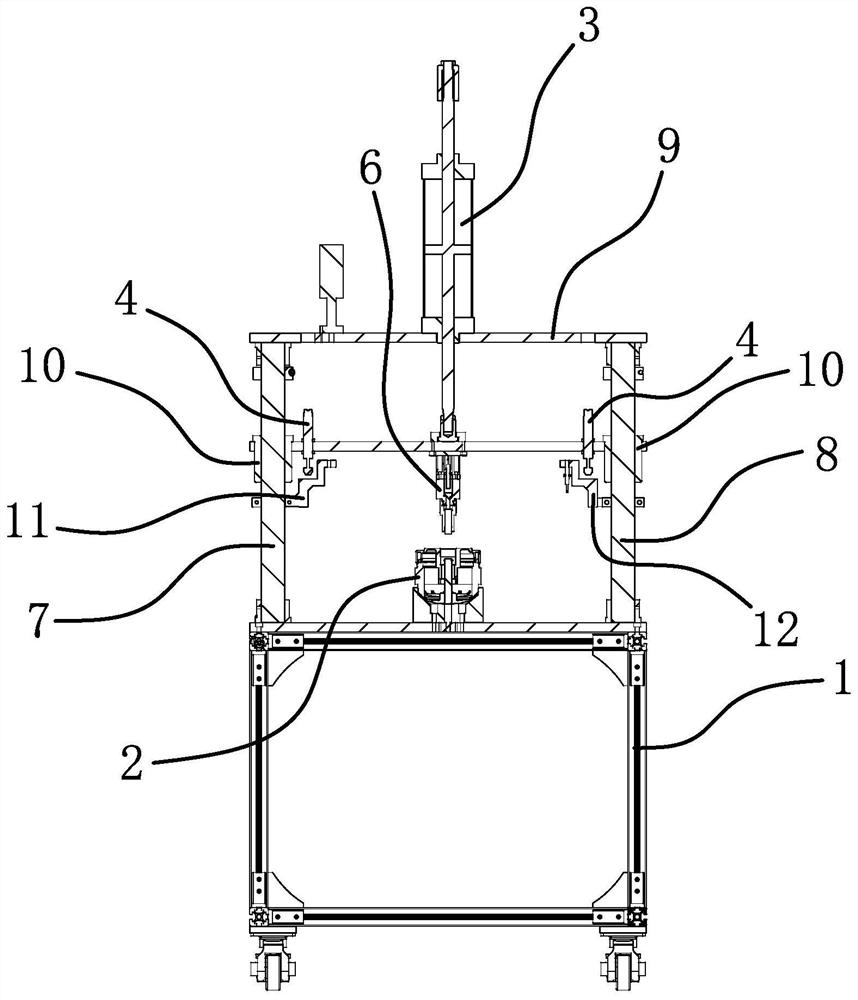

[0030] Such as figure 1 and figure 2 As shown, a pressure detection circlip tooling, including a frame, is characterized in that it also includes a connecting seat, a driver, a sensor, a pressure plate and a contact head. The above connecting seat is used to connect the detected workpiece and the connecting seat is fixed on the machine. At the middle part of the frame, the above-mentioned driving part is fixedly connected to the top of the frame, the above-mentioned pressure plate is connected to the frame and the pressure plate is connected with the driving part, the driving part can drive the pressure plate to move up and down smoothly along the frame, and the above-mentioned contact head is fixedly connected to the lower part of the pressure plate And the contact head is located directly above the connecting seat, the above-mentioned sensor is located between the pressing plate and the frame, and the above-mentioned sensor can detect the displacement of the pressing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com