Automatic press-fit antiskid chain forming machine

An anti-skid chain, automatic technology, applied in the direction of metal chains, etc., can solve the problems of easy falling off gussets, slow processing speed, cumbersome processes, etc., and achieve the effect of increasing the speed of delivery materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

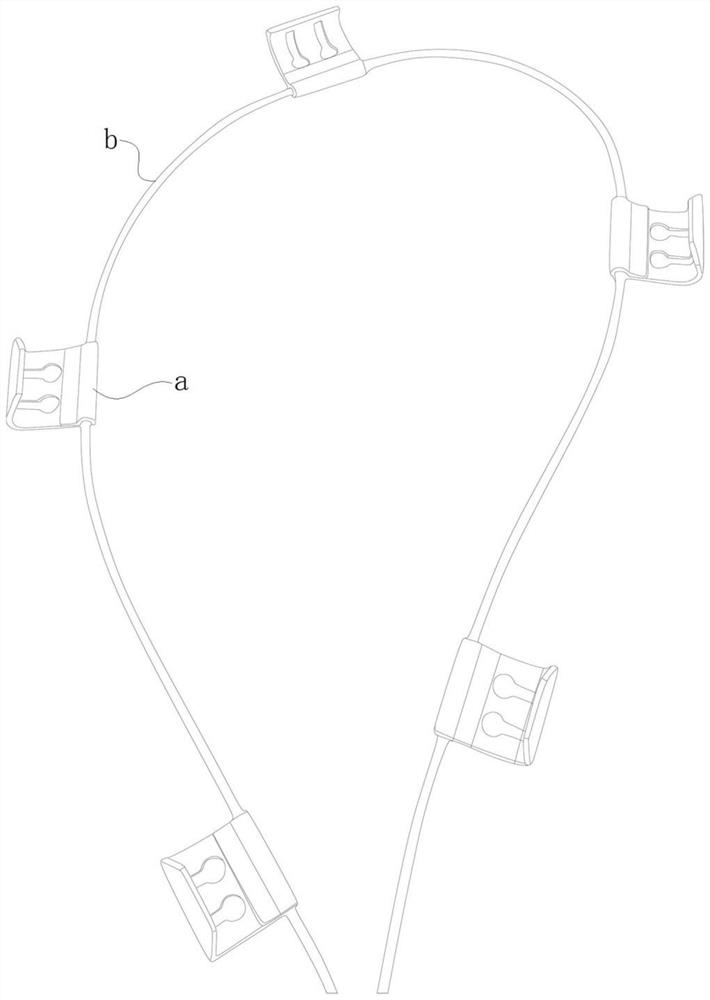

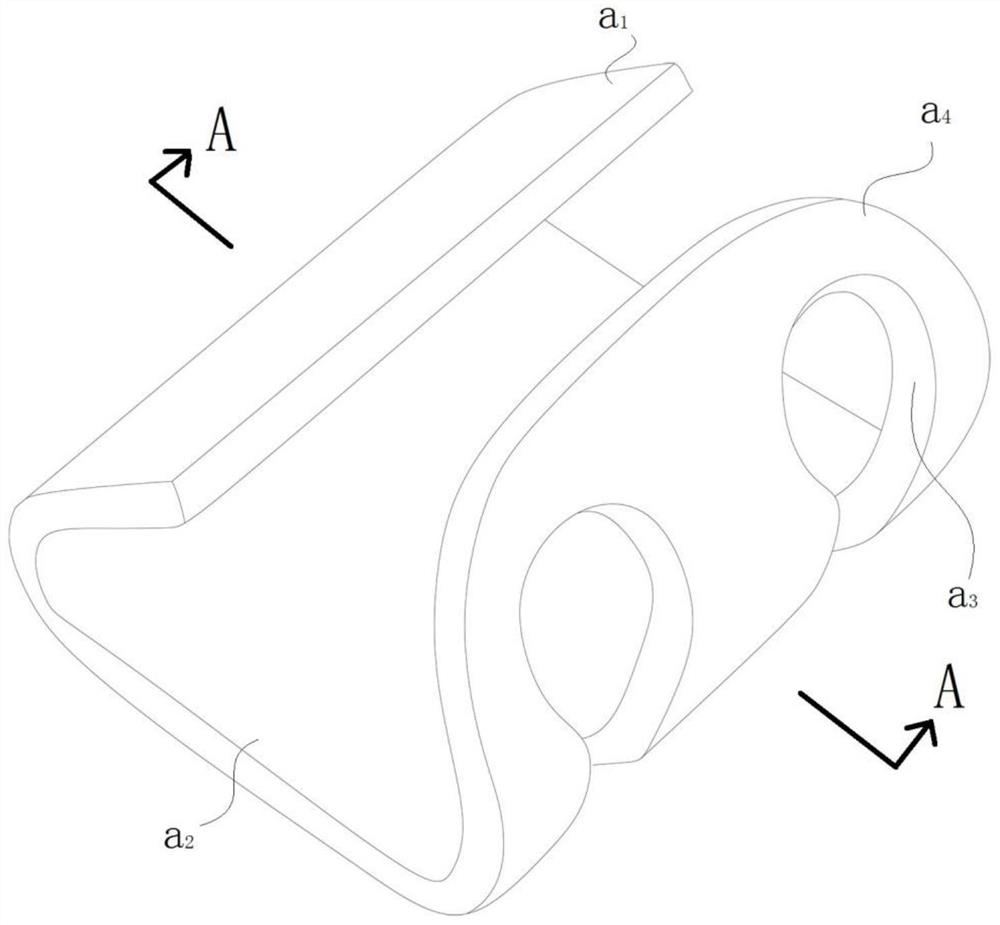

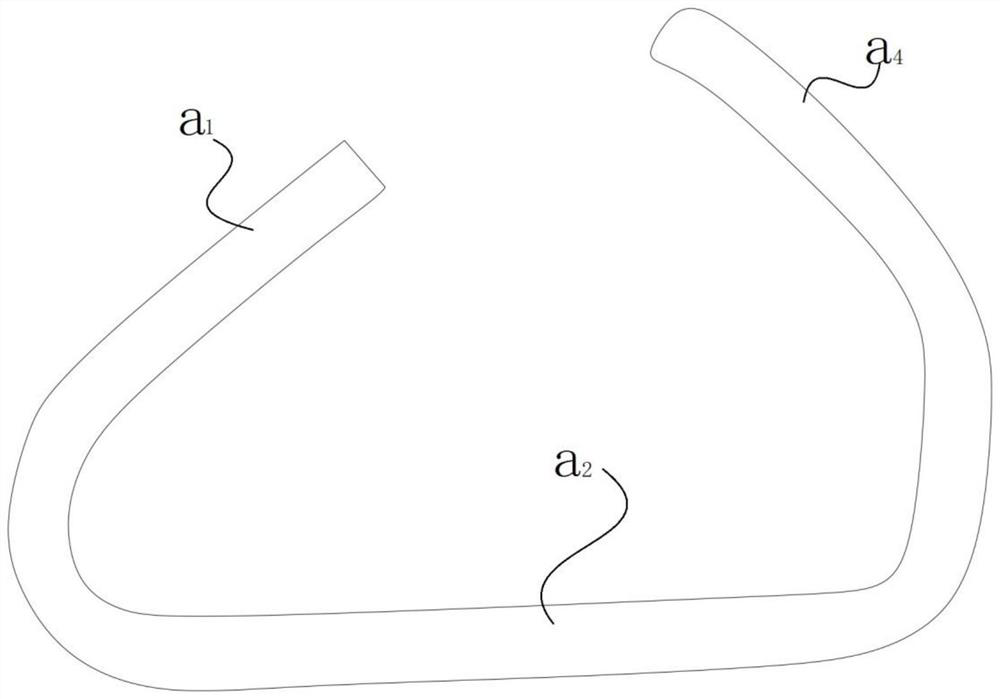

[0032] Referring to Fig. 1 to Fig. 1 of the accompanying drawings of the description of the present invention Figure 8As shown, according to a preferred embodiment of the present invention, an automatic pressing anti-skid chain forming machine is described; the automatic pressing anti-skid chain forming machine includes a rope body b feeding mechanism, a gusset part feeding mechanism arranged on the frame mechanism and a stamping mechanism 3 for press-fitting the gusset a to the rope body b, the gusset feeding mechanism includes vibrating discs 7 and hook pull assemblies 4 respectively located at the front and rear ends of the stamping mechanism 3, and The vibrating plate 7 vibrates and feeds the buckle a, the rope body b passes through one end of the buckle a and at least one section of the rope b stays in the end of the buckle a; the stamping end of the stamping mechanism 3 For the end part a of the gusset part with a section of rope body b placed 1 Stamping and pressing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com