Glazing method of heat-resistant ceramic

A heat-resistant and ceramic technology, applied in the field of heat-resistant ceramic production, can solve problems such as repairing glaze marks, poor splicing of repairing glaze lines, poor glazing of clamping parts, etc., to ensure integrity, ensure assembly line production, and eliminate overall The effect of poor glazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

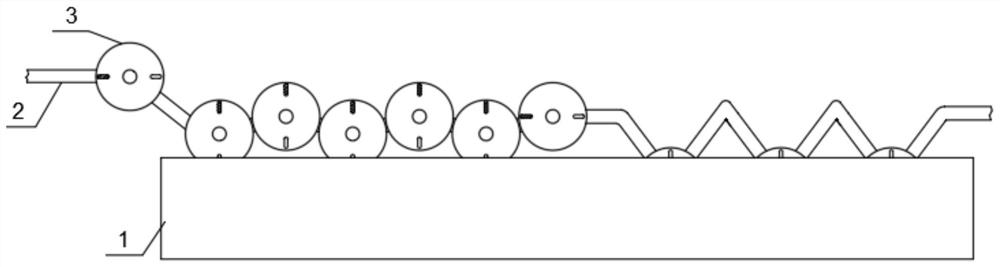

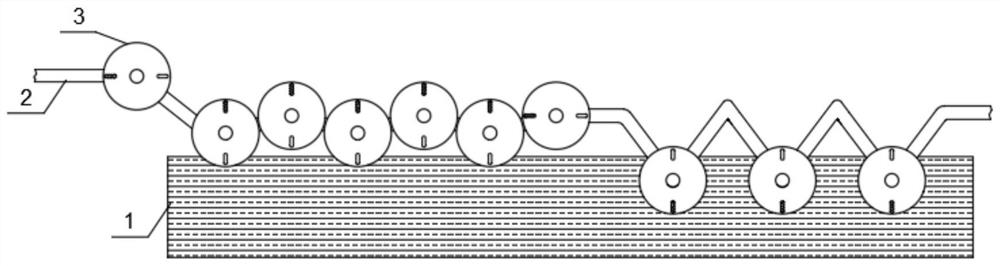

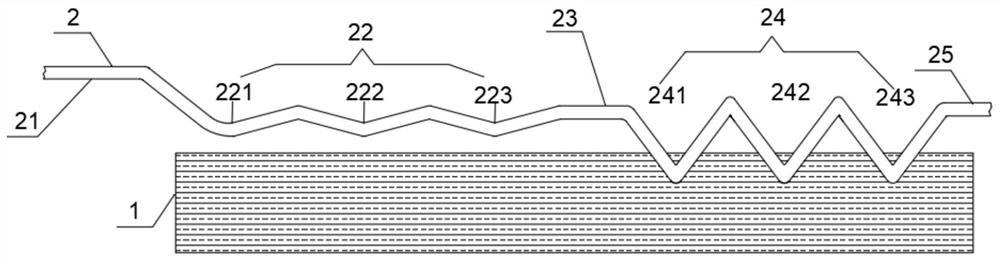

[0035] A heat-resistant ceramic glazing line, including a glaze box 1, a guide rail 2, and a rotating mechanism 3; the guide rail 2 is located above the glaze box 1; a rotating shaft 32 is arranged on the back of the rotating mechanism 3; , the rotating mechanism 3 moves in the guide rail 2 through the rotating shaft 32, and the rotating mechanism 3 can rotate with the rotating shaft 32 as the center of a circle; the rotating mechanism 3 is provided with a left hook 33 and a right hook 34; Ear 41 and right ear 42; the heat-resistant ceramic body 4 is hung on the rotating mechanism 3, wherein the left ear 41 is hung on the left hook 33, and the right ear 42 is hung on the right hook 34; the guide rail 2 is divided into the inlet 21 and the right ear Glazing section 22, advection section 23, overall glazing section 24, and outlet 25; the rotating mechanism...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap