Film pasting device and film pasting system for small-size glass

A film sticking device and small-sized technology, applied in packaging and other directions, can solve the problems of difficult adsorption on the upper plate, film cannot be vacuumed, and is not applicable, and achieve the effect of improving the bonding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

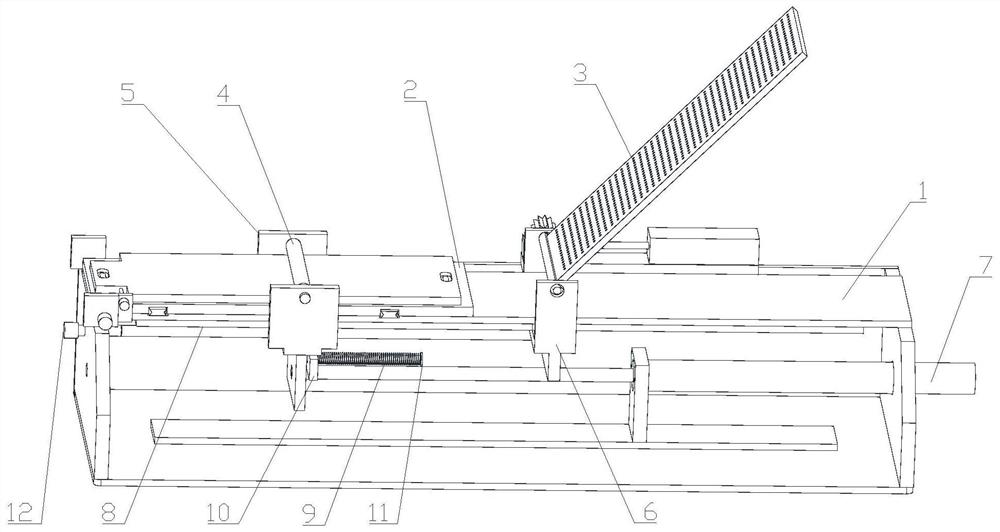

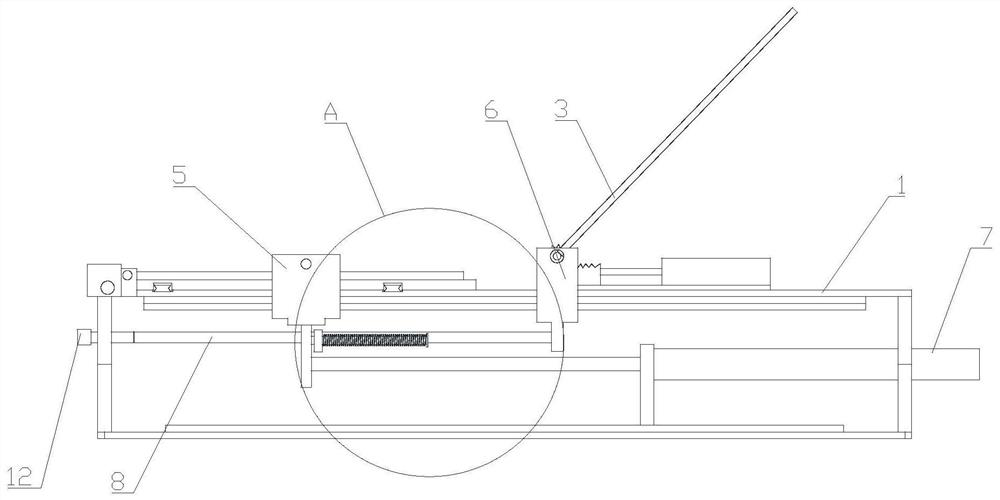

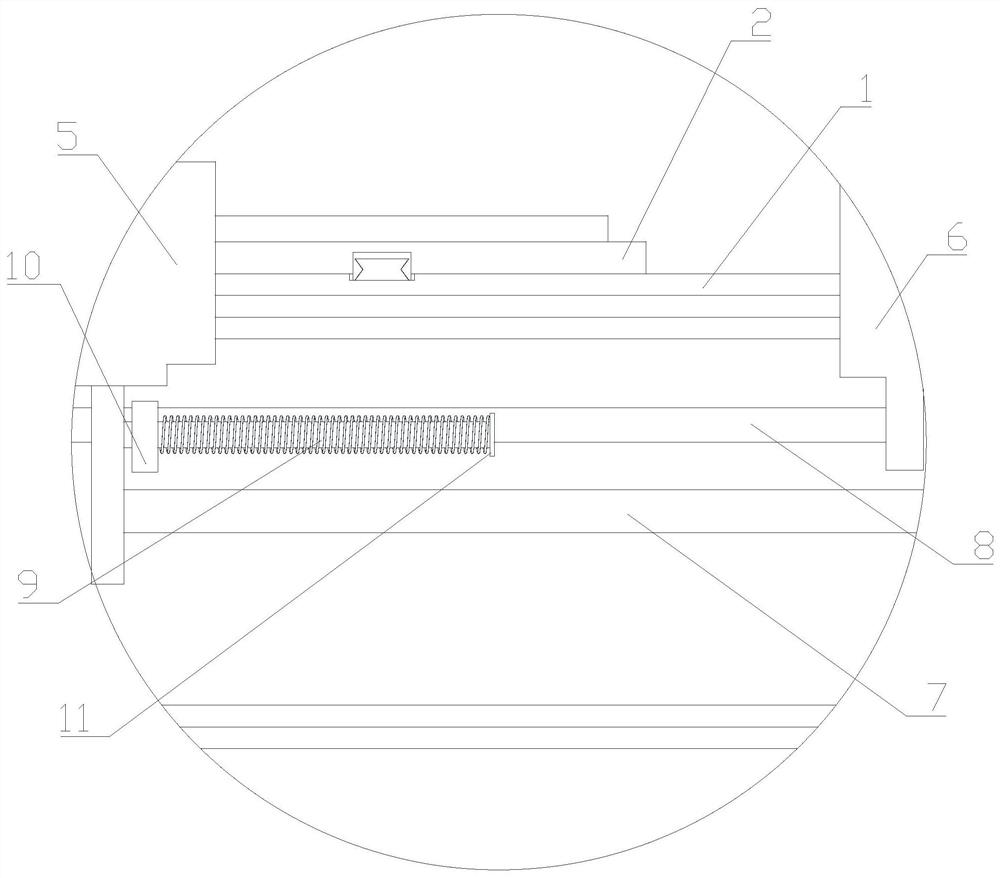

[0037] Such as figure 1 as shown, figure 1 It is a three-dimensional schematic diagram of a film sticking device that can be used for small-sized glass proposed by the present invention; figure 2 It is a schematic front view of a film sticking device for small-sized glass proposed by the present invention; image 3 for figure 2 Enlarged view of A; Figure 4 It is a schematic top view of a film sticking device for small-sized glass proposed by the present invention.

[0038] refer to Figure 1-Figure 4 , a film sticking device that can be used for small-sized glass proposed by the present invention includes: a workbench 1, a suction template 2, a suction template 3, pressing rollers and a movable seat 6;

[0039] The lower suction template 2 is arranged on the workbench 1, and the lower suction template 2 has opposite first and second ends in the first horizontal direction;

[0040] The pressing rollers are arranged on the workbench 1 outside the first end of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com