A method and system for automatic identification of roll eccentricity based on hot-rolled strip rolling force

An automatic identification and hot-rolled strip technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of roll eccentricity degree analysis, roll eccentricity non-conformity, affecting the normal rolling of strip steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

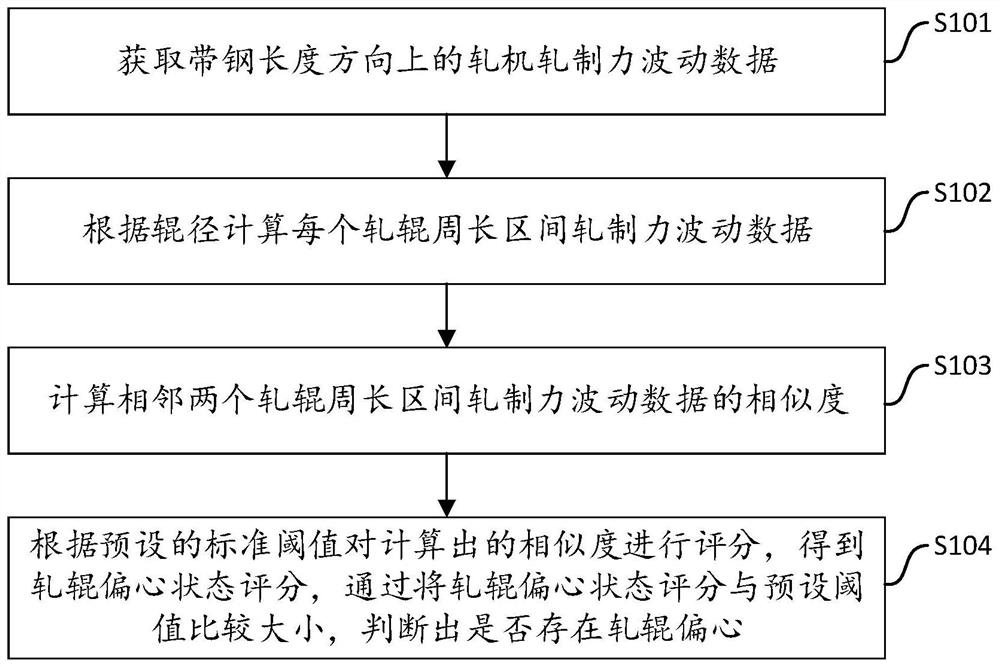

[0066] This embodiment provides a method for automatically identifying roll eccentricity based on the rolling force of hot-rolled strip steel. The method can be implemented by electronic equipment, and the electronic equipment can be a terminal or a server. The execution flow of the automatic identification method of roll eccentricity based on the rolling force of hot-rolled strip steel is as follows: figure 1 shown, including the following steps:

[0067] S101, acquiring rolling force fluctuation data of the rolling mill in the strip length direction;

[0068] S102, calculating the rolling force fluctuation data in the perimeter interval of each roll according to the roll diameter;

[0069] S103, calculating the similarity of the rolling force fluctuation data in the perimeter intervals of two adjacent rolls;

[0070] S104, scoring the calculated similarity according to a preset standard threshold to obtain a roll eccentricity score, and comparing the roll eccentricity scor...

no. 2 example

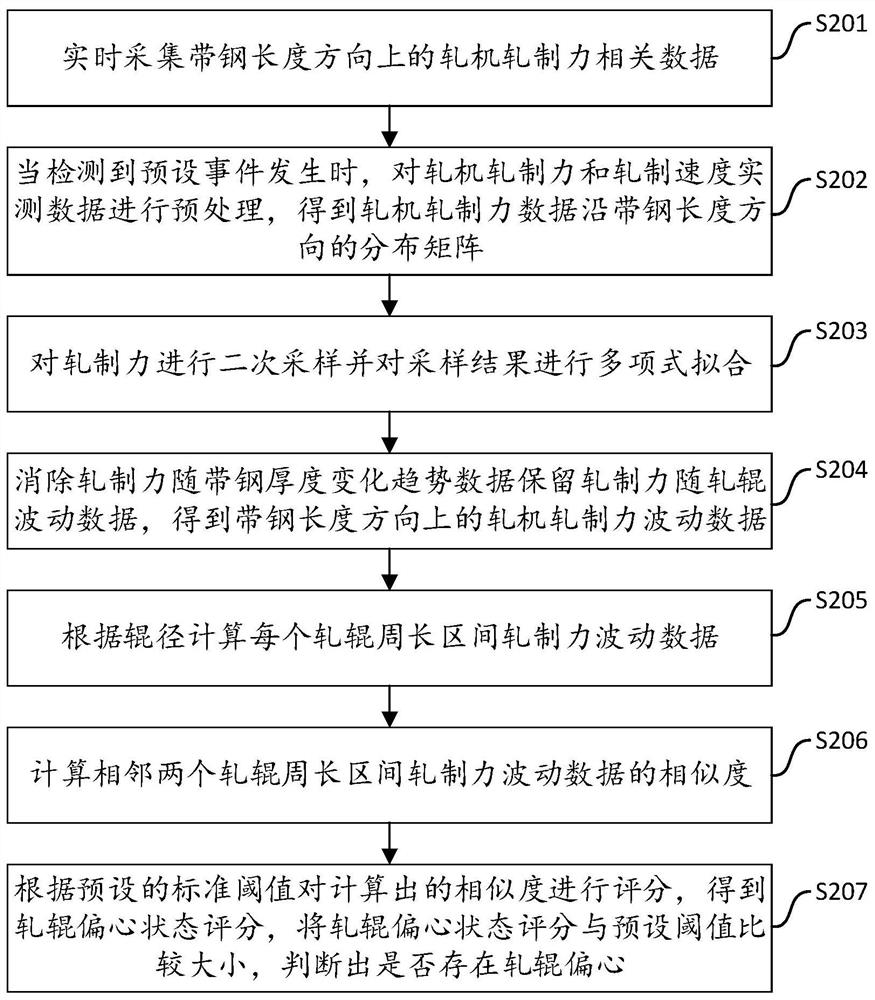

[0073] This embodiment provides a method for automatically identifying roll eccentricity based on the rolling force of hot-rolled strip steel. The method can be implemented by electronic equipment, and the electronic equipment can be a terminal or a server. The execution flow of the automatic identification method of roll eccentricity based on the rolling force of hot-rolled strip steel is as follows: figure 2 shown, including the following steps:

[0074] S201, collecting data related to the rolling force of the rolling mill in the strip length direction in real time;

[0075] Wherein, the rolling force-related data acquired in this embodiment includes but not limited to: rolling mill roll diameter, rolling mill bite and steel throwing signals, rolling mill rolling force and rolling speed measured data.

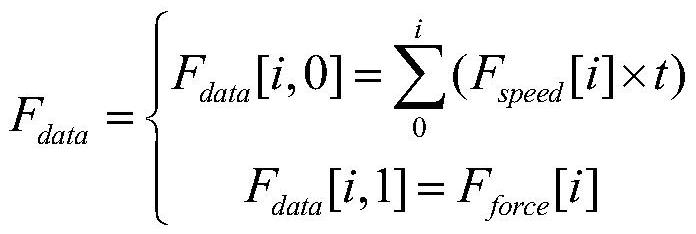

[0076] S202, when it is detected that a preset event occurs, preprocess the measured data of the rolling force and rolling speed of the rolling mill to obtain the distribu...

no. 3 example

[0125] The present embodiment provides a roll eccentricity automatic recognition system based on hot-rolled strip rolling force, the roll eccentricity automatic recognition system based on hot-rolled strip rolling force includes the following modules:

[0126] The rolling force fluctuation acquisition module is used to obtain the rolling force fluctuation data of the rolling mill in the strip length direction;

[0127] The fluctuation data calculation module is used to calculate the rolling force fluctuation data of each roll circumference interval according to the roll diameter;

[0128] The similarity calculation module is used to calculate the similarity of rolling force fluctuation data in the perimeter interval of two adjacent rolls;

[0129] The roll eccentricity automatic identification module is used to score the similarity calculated by the similarity calculation module according to the preset standard threshold to obtain the roll eccentricity state score, and compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com