Tailored-welding method for sheet metal parts

A sheet metal part, together technology, applied in the field of tailor welding between sheet metal parts, can solve problems such as inability to handle and affect the appearance quality, and achieve the effect of ensuring structural strength and appearance quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A specific embodiment of a tailor welding method between sheet metal parts according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] A tailor welding method between sheet metal parts according to the present invention, the steps are:

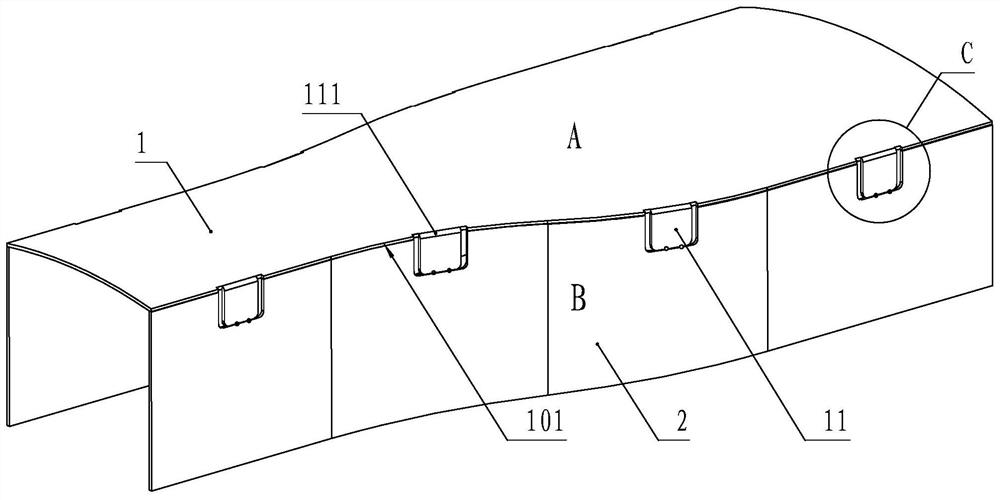

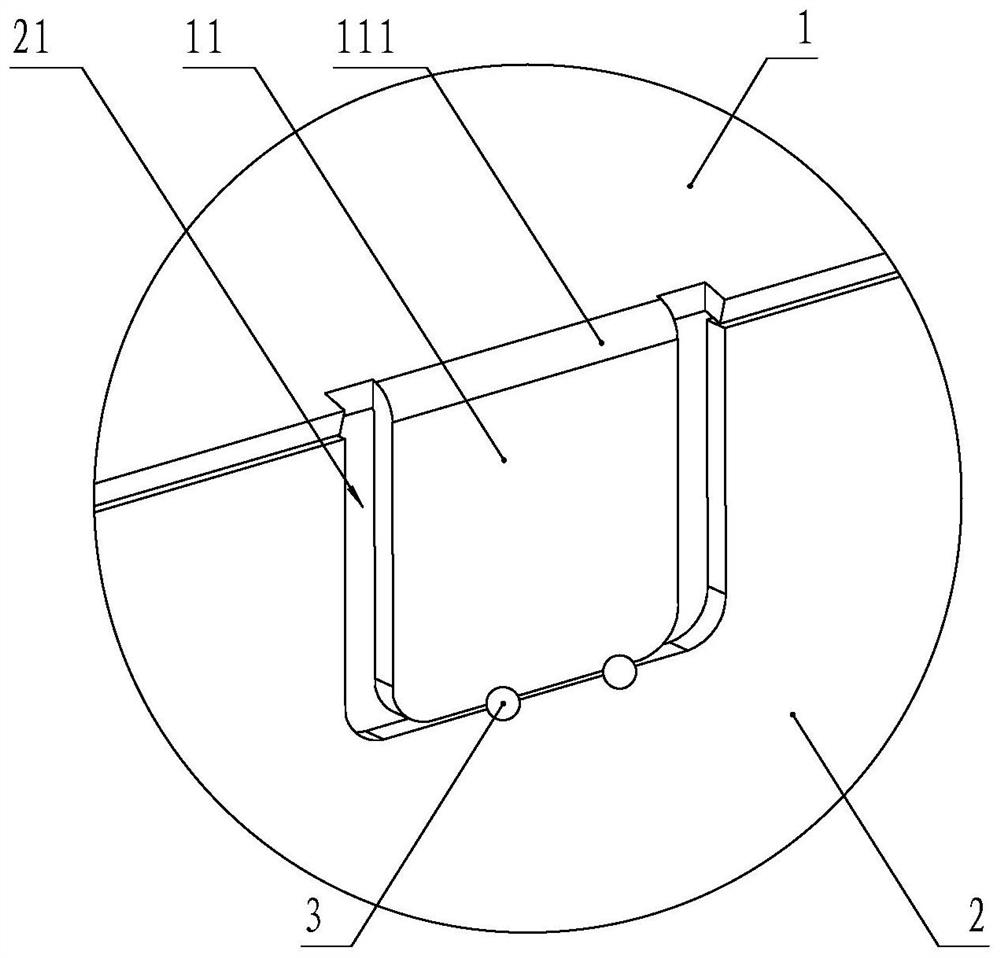

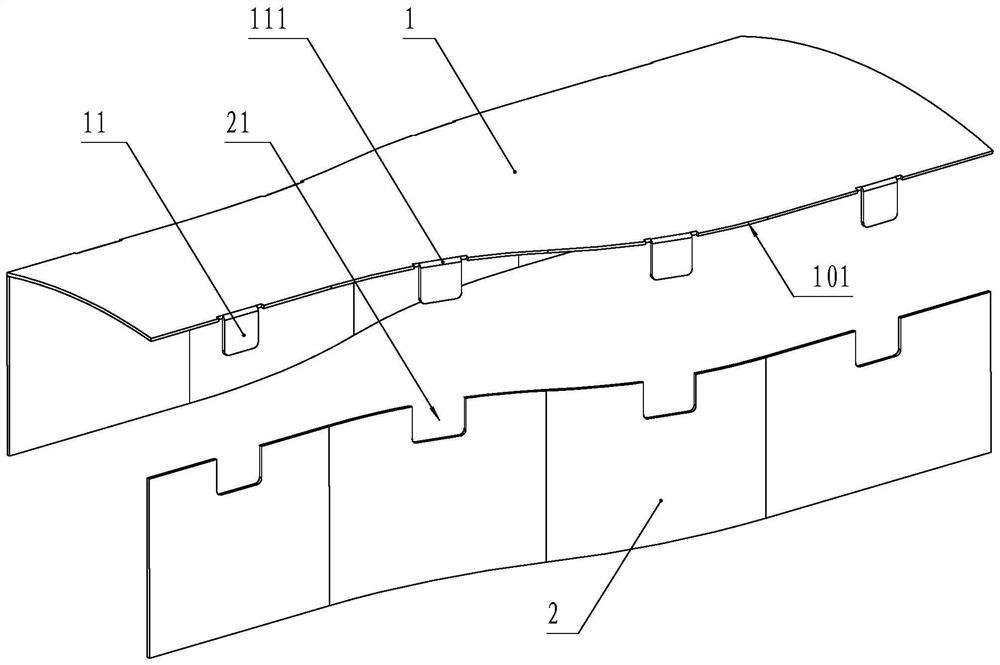

[0016] 1) if image 3 As shown, when punching the first sheet metal piece 1 that includes the appearance surface A, four inwardly bent splicing tabs 11 (splicing tabs 11 ) are punched out at the edge of the appearance surface A of the first sheet metal piece 1. The number depends on the actual situation, the splicing lug 11 is located in the hidden surface B), and, when designing the stamping die of the first sheet metal part 1, it should be ensured that the outer surface of the splicing lug 11 does not exceed the appearance surface A The end surface 101 on the corresponding side of the splicing lug 11 forms a transitional connection portion 111 at the junction of the app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com