Tire sidewall line structure and tire applying same

A sidewall and texture technology, applied to the sidewall of the tire, tire parts, transportation and packaging, etc., can solve the problems of weak sidewalls and poor puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 1-7 The application is described in further detail.

[0045] The embodiment of the present application discloses a tire sidewall texture structure.

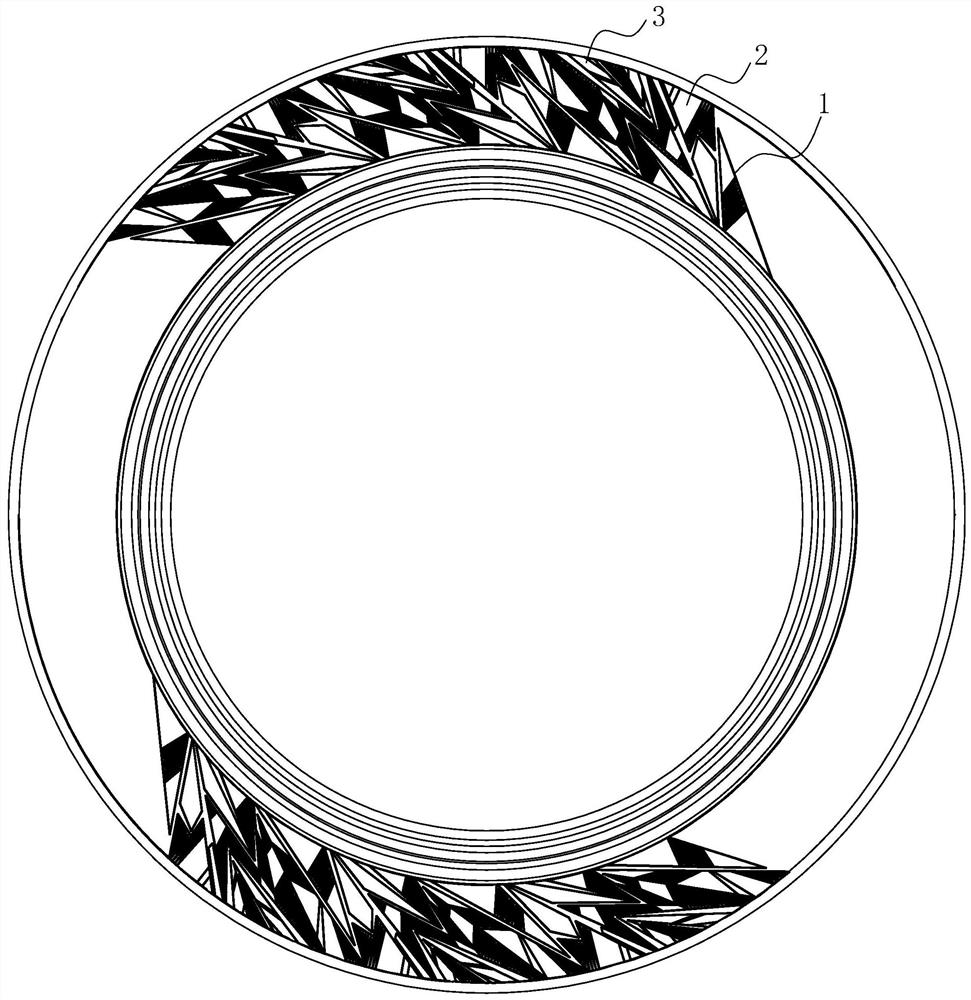

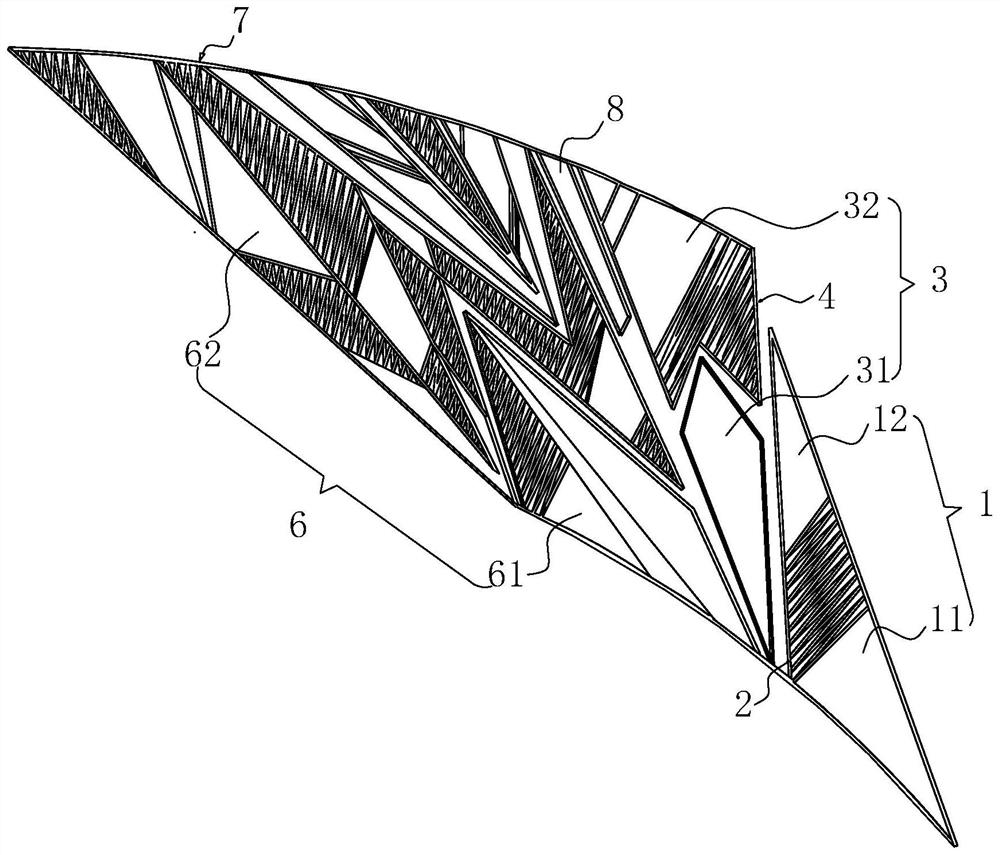

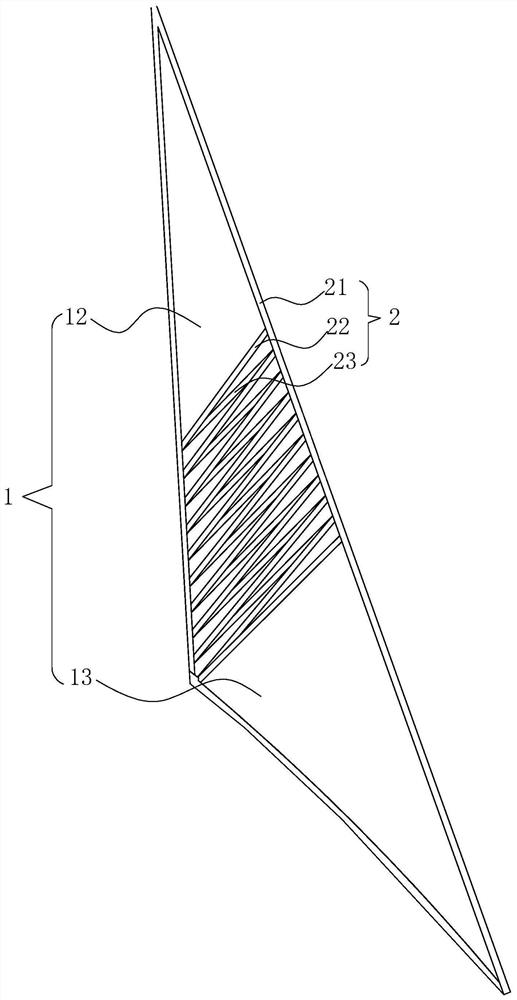

[0046] refer to figure 1 and figure 2 A tire sidewall texture structure includes a texture group arranged on the tire sidewall, at least one set of the texture group is arranged along the circumferential direction of the tire sidewall. The pattern group includes the first pattern block group 1, the second pattern block group 3 and the third pattern block group 6 arranged in sequence along the same circumferential direction of the tire sidewall, the first pattern block group 1, the second pattern block group 3 and the third pattern block group The block groups 6 are respectively provided with a first group of interlaced lines 2, a second group of interwoven lines 4 and a third group of interwoven lines 7 for improving the puncture resistance of the sidewall. The directions are arranged...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap