Concrete pump truck supporting leg device and using method

A technology for concrete pump trucks and support parts, which is applied in the field of automobile support, and can solve the problems of uneven pads, random use of pump truck pads, eccentric placement, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

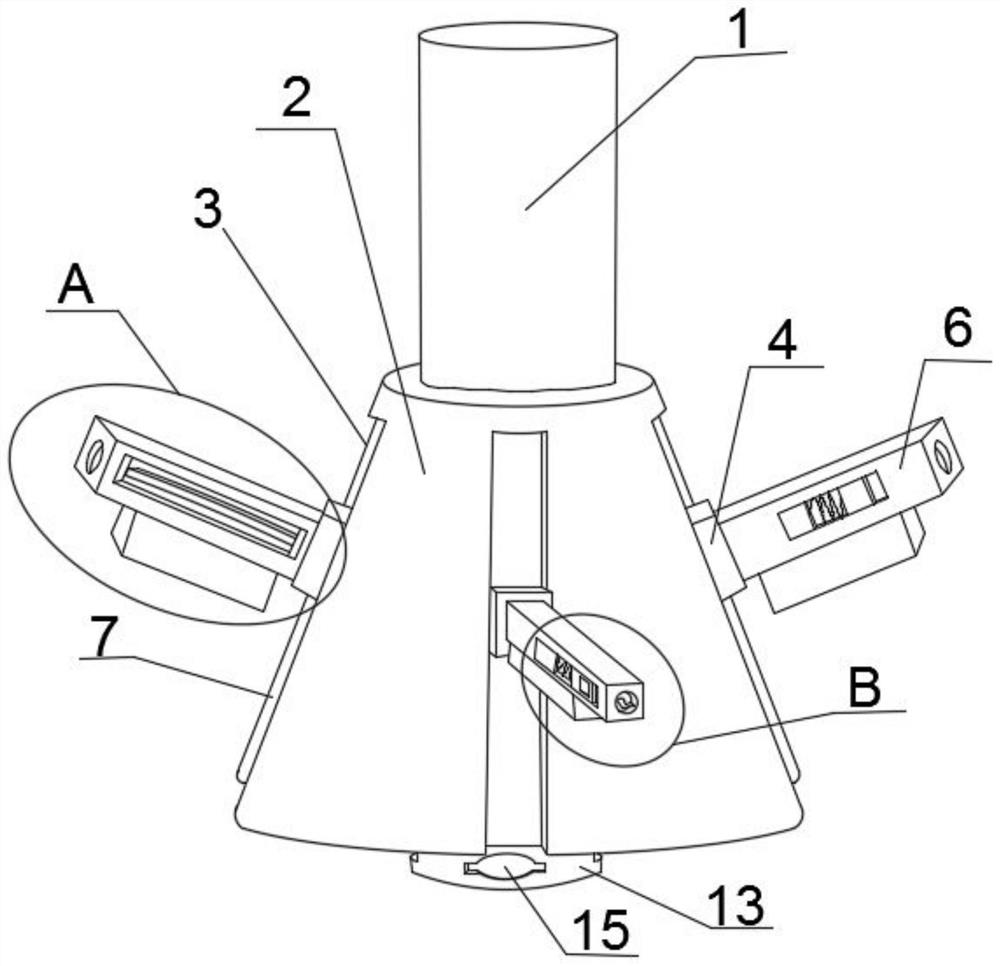

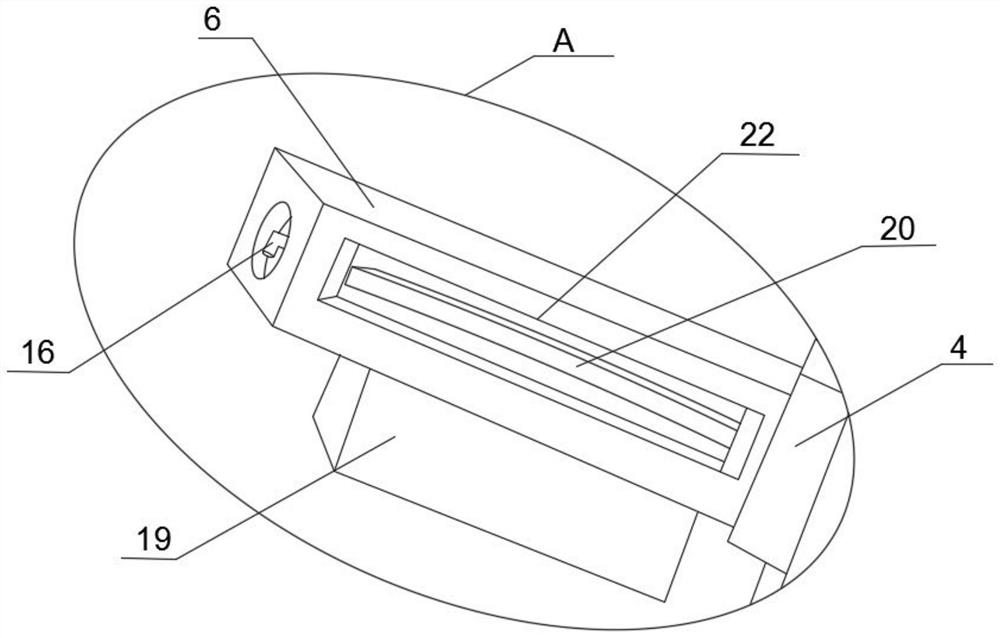

[0040] Such as Figure 1 to Figure 7 Shown: an embodiment of the present invention, a concrete pump truck outrigger device, the outrigger includes a hydraulic rod 1 and a bearing frame 2, the hydraulic rod 1 is fixedly connected to the carrier frame 2, and the carrier frame 2 includes a chute group 3, There are multiple groups of chute groups 3, and the multi-groups of chute groups 3 are circumferentially distributed on the surface of the carrier frame 2, and each group of chute groups 3 is equipped with a slider 4, which is slidably connected with the chute group 3 The slider part 4 is provided with a pair of perforations 5, the pair of perforations 5 are through holes, and a support part 6 is installed in the pair of perforation holes 5, the support part 6 is fixedly connected with the slider part 4, and the support part 6 is suitable for supporting the hydraulic rod 1.

[0041] Each chute group 3 includes a first track 7 and a second track 8 , the second track 8 is located ...

Embodiment 2

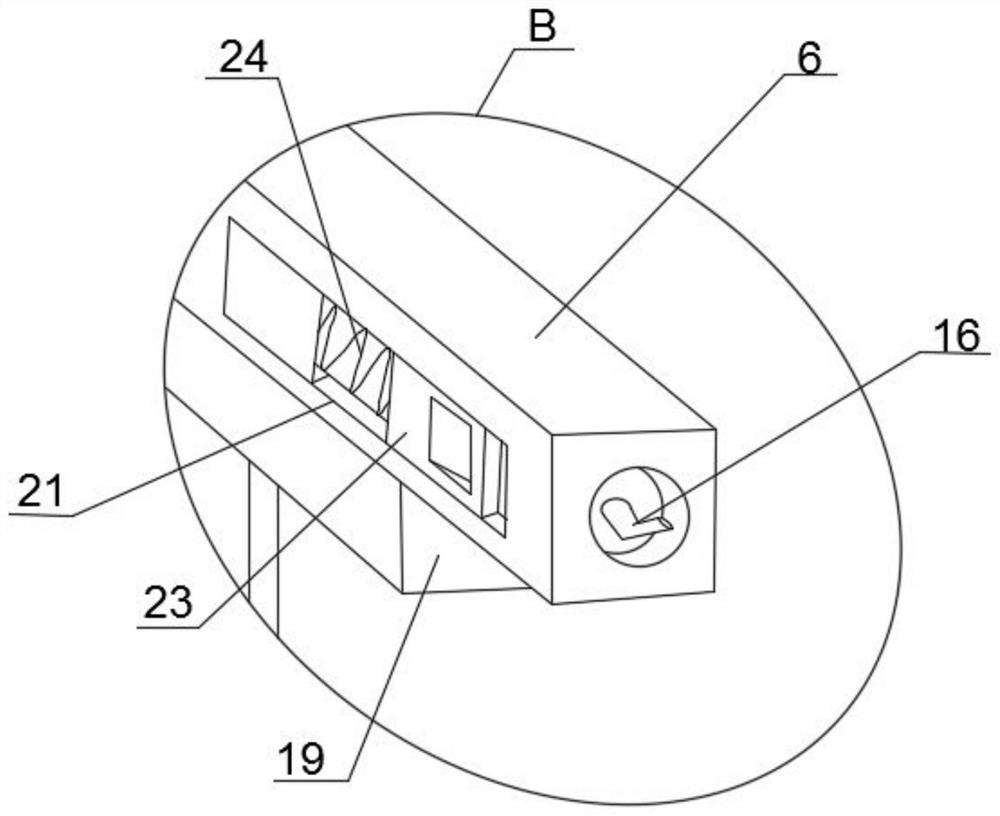

[0057] Such as Figure 8 As shown, it is another embodiment of the present invention. On the basis of Embodiment 1, the modification is as follows, the support member 6 is connected to the slider member 4 in rotation, and the support part 18 is provided with a rotating rod 20 and a bayonet groove 21, The supporting part 18 is provided with a rotating groove 22, the rotating groove 22 is suitable for installing the rotating rod 20, one end of the rotating rod 20 is rotationally connected with the rotating groove 22, and the other end of the rotating rod 20 is matched with the bayonet groove 21;

[0058] Each set of supporting parts 18 is provided with a rotating rod 20 and a bayonet slot 21 , and the rotating rod 20 is suitable for connecting with the bayonet slot 21 on the adjacent supporting part 18 .

[0059] The connecting part 17 is rotationally connected with the slider part 4, the rotating rod 20 is an arc rod, the position of the bayonet groove 21 is different from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com