Sweet potato starch block crushing and collecting equipment

A technology for collecting equipment and sweet potato starch, which is applied in grain processing, etc., can solve the problems of increased starch cost, reduced labor intensity, and reduced work efficiency, and achieves the effects of saving time and manpower, reducing damage, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

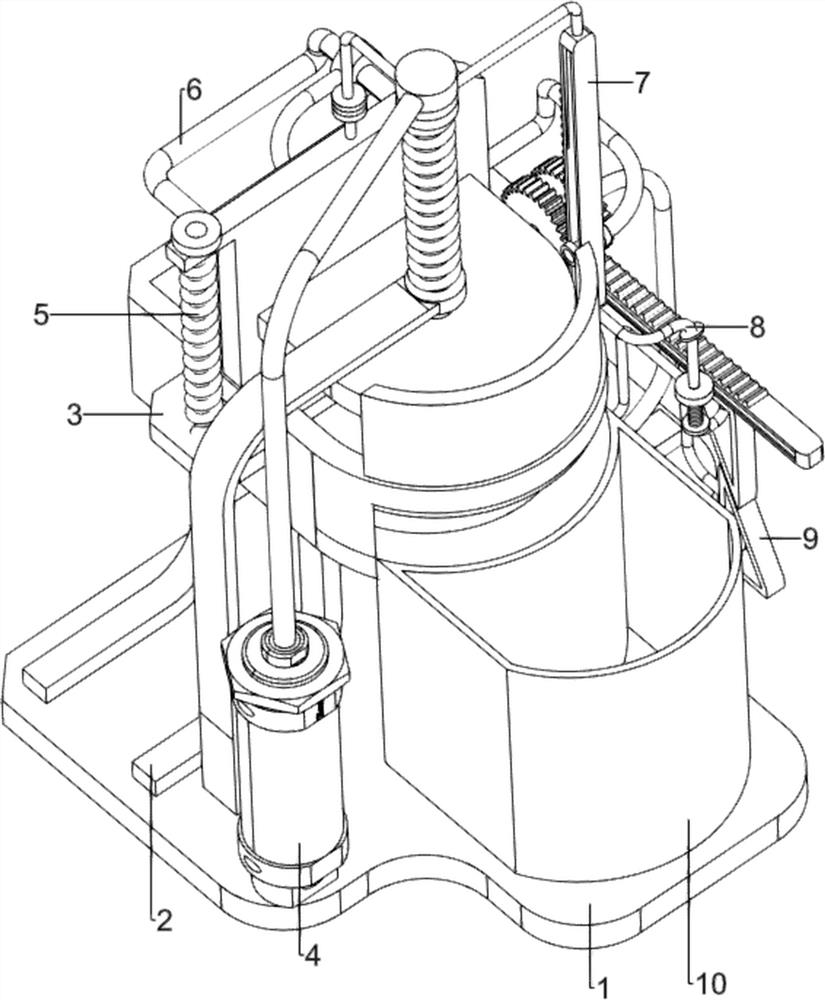

[0058] A sweet potato starch block crushing and collecting equipment, such as Figure 1-2 As shown, it includes a bottom plate 1, a feeding table 2, a small iron block 3 and a starch pressing mechanism 4, the bottom plate 1 is provided with a feeding table 2 at the rear, and the left side of the feeding table 2 is provided with a small iron block 3, and the bottom plate 1 There is a starch pressing mechanism 4 on the left side of the front part.

[0059] When people need to grind the starch block, people place the starch block in the feeding table 2, and people open the starch pressing mechanism 4, so that the starch pressing mechanism 4 squeezes the starch block, and after the starch block is crushed, the pressed starch is pressed. The mechanism 4 is closed, and the starch in the feeding table 2 is taken out.

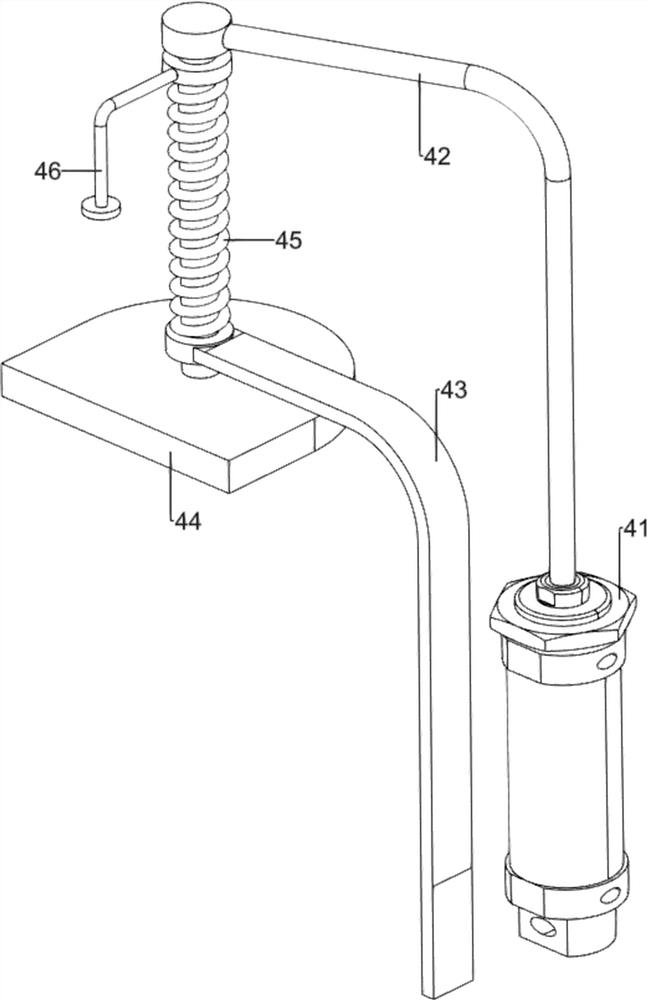

[0060] The starch pressing mechanism 4 includes an air cylinder 41, a push rod 42, a first support frame 43, a lower pressure device 44, a first spring 45 and a lower...

Embodiment 2

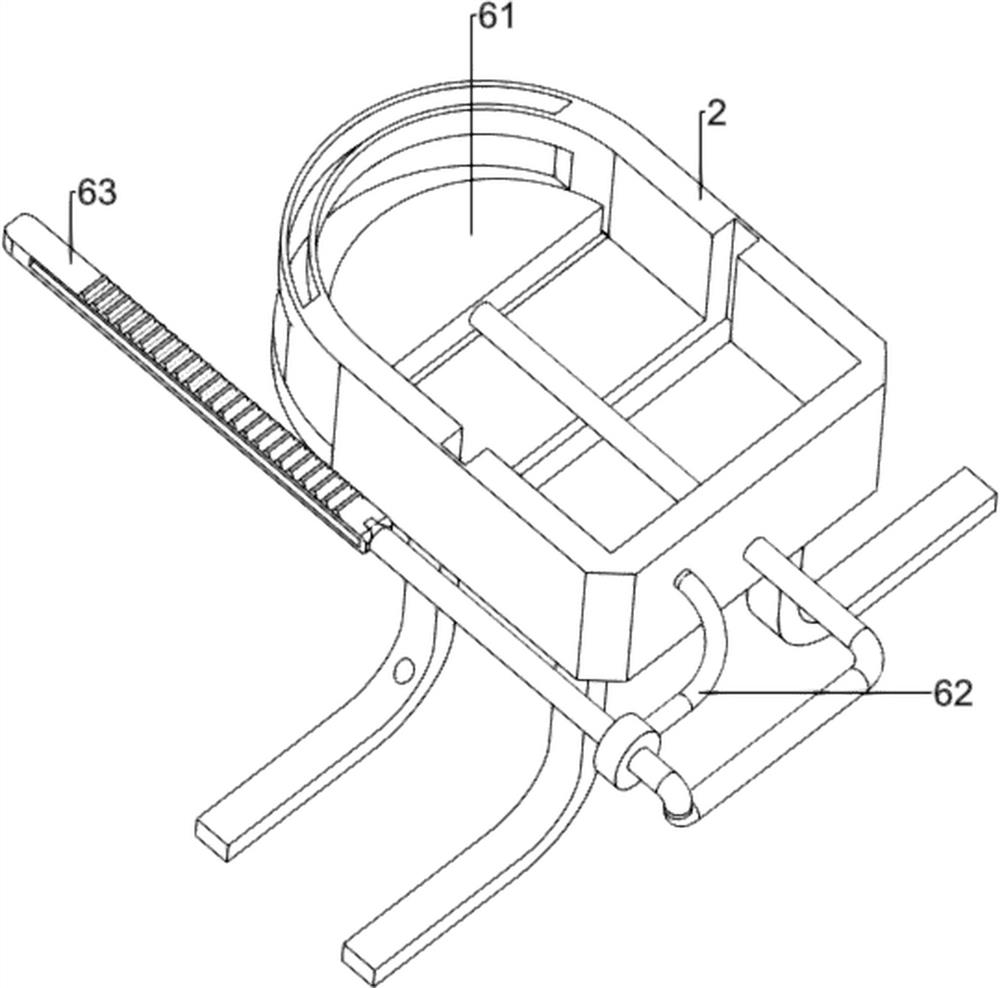

[0065] On the basis of Example 1, as figure 1 , Figure 3-Figure 7 As shown, a push mechanism 6 is also included, and the push mechanism 6 includes a pusher 61, a first stable frame 62 and a first rack 63. A pusher 61 is provided inside the feeding table 2, and a pusher 61 is provided on the outside of the pusher 61. A first stable frame 62 is provided, and a first rack 63 is provided on the top of the right side of the pusher 61 .

[0066] When the starch block is crushed into starch, when the partition board 51 moves upward, people manually pull the first rack 63, and the first rack 63 drives it to move forward. The pusher 61 is stabilized, so that the pusher 61 pushes out the starch in the feeding table 2, and people collect the starch. When people collect the starch, they manually push the first rack 63, and the first rack 63 drives the pusher The feeder 61 moves backwards and no longer pushes out the starch.

[0067] Also includes an automatic push auxiliary mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com