Lamp diffuser plate thickness detection device

A thickness detection and diffusion plate technology, applied in sorting and other directions, can solve problems such as the inability to separate diffusion plates of different thicknesses, and the inability to detect the thickness of diffusion plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

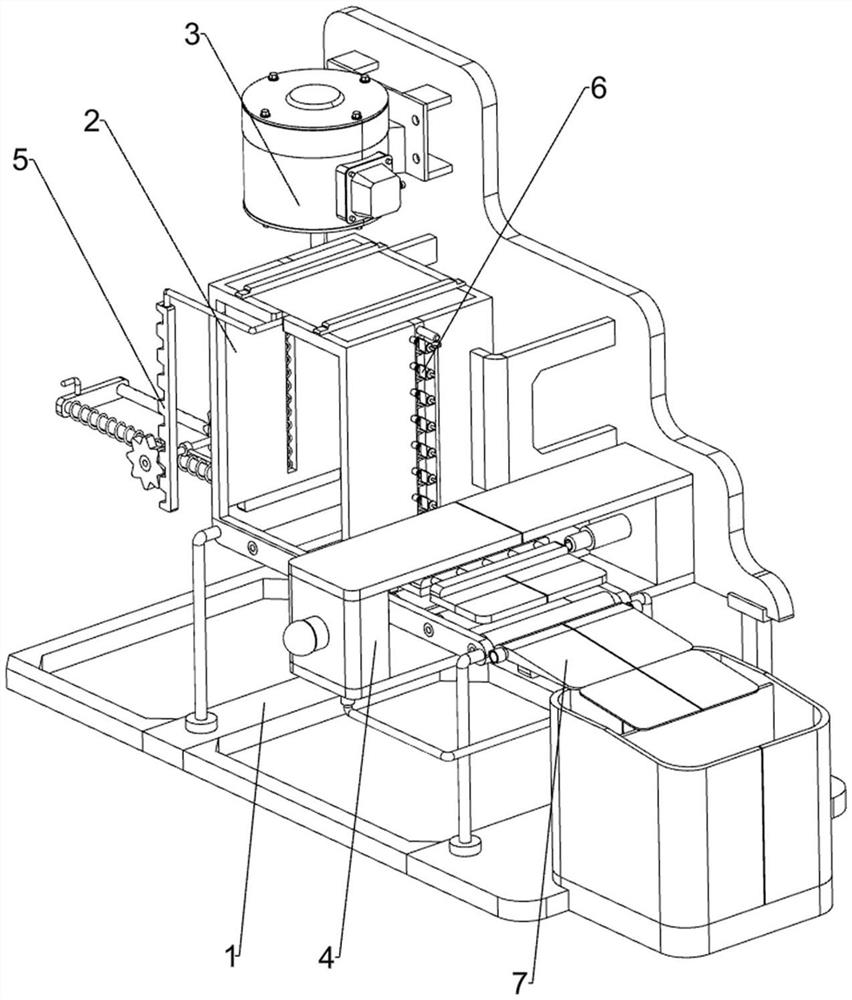

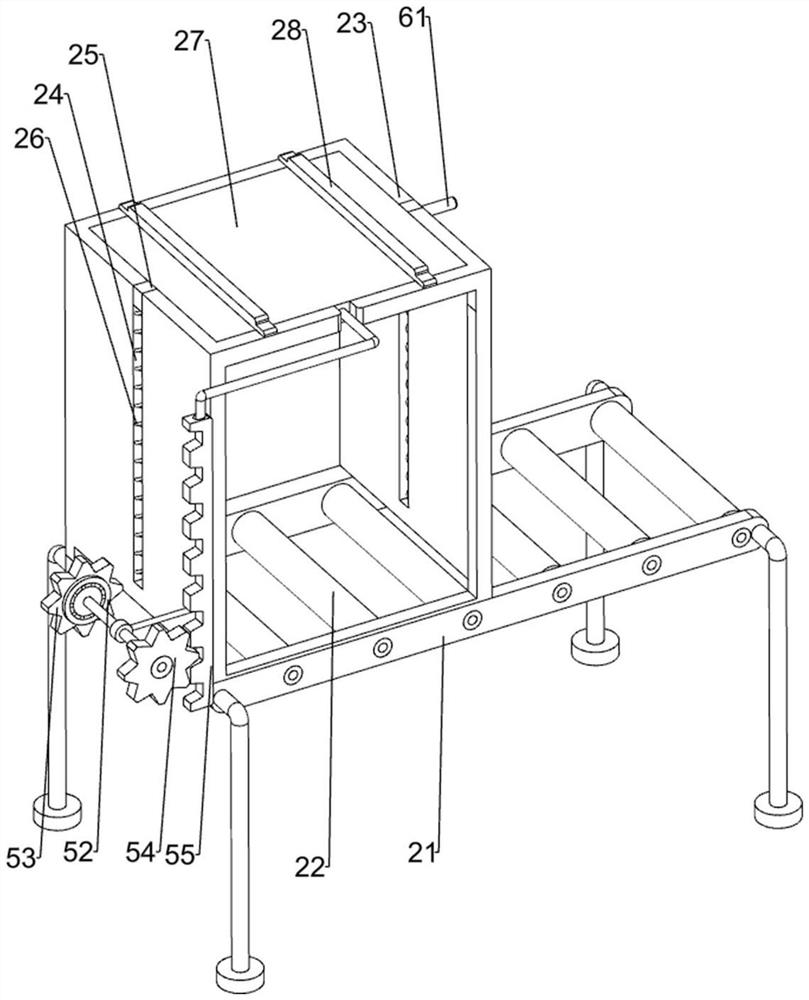

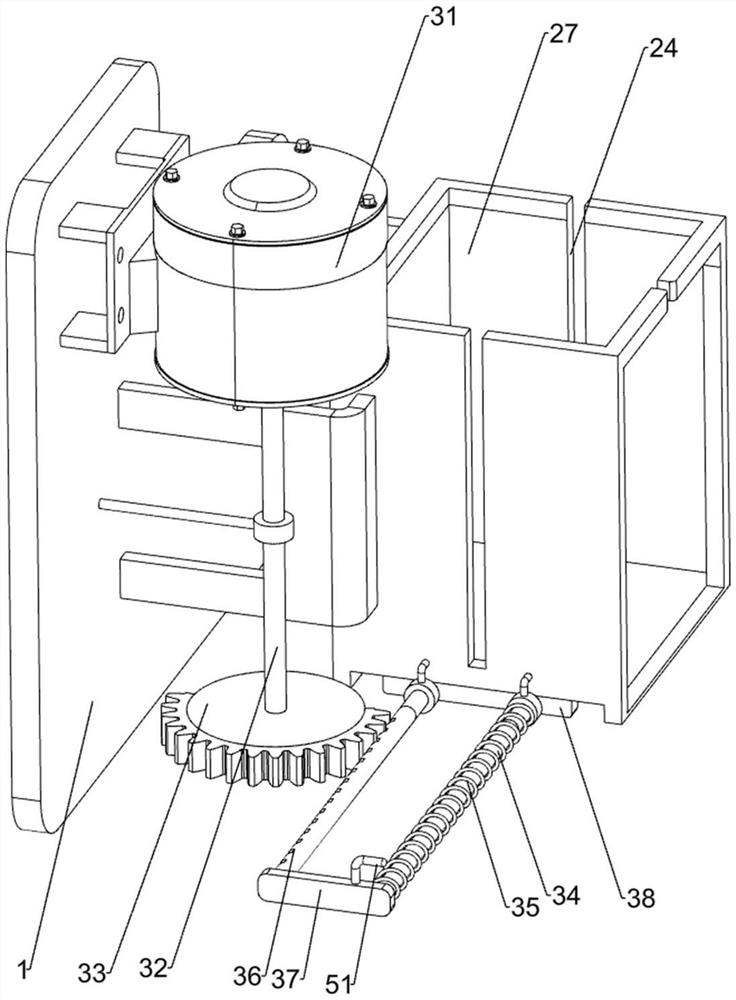

[0023] A device for detecting the thickness of a diffuser plate of a lamp, such as Figure 1-Figure 5 As shown, it includes a mounting base 1, a blanking assembly 2, a pushing assembly 3 and a detection assembly 4. The mounting base 1 is used to install the entire device, and the left part of the mounting base 1 is provided with a blanking assembly 2 that performs blanking by sliding The upper part of the right side of the mounting base 1 is provided with a pusher assembly 3 that provides power for material pushing, and the right part of the mounting base 1 is provided with a detection assembly 4 through laser detection.

[0024] When it is necessary to detect the thickness of the diffusion plate, the staff first places a certain amount of diffusion plate into the blanking assembly 2, and then starts the pushing assembly 3 to push the diffusion plate in the blanking assembly 2 to the bottom of the detection assembly 4, and then The staff can collect the diffuser plates that ha...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 with figure 2 As shown, the push assembly 5 includes an L-shaped rod 51, an overrunning clutch 52, a first gear 53, a second gear 54 and a rack 55, the front side of the connecting plate 37 is welded with an L-shaped rod 51, and the lower part of the left side of the frame body 23 The rotary type is provided with an overrunning clutch 52, the outside of the overrunning clutch 52 is provided with a first gear 53, the first gear 53 cooperates with the L-shaped bar 51, the front end of the overrunning clutch 52 transmission shaft is provided with a second gear 54, and the front side of the pressing plate 27 is fixed by screws. A rack 55 is connected, and the rack 55 cooperates with the second gear 54 .

[0033] When the connecting plate 37 moves to the right, it drives the L-shaped bar 51 to move to the right. When the L-shaped bar 51 contacts the first gear 53, it pushes the first gear 53 to rotate, and drives the overrunning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com