Air bag polishing head mechanism capable of adjusting pressure in sections and air bag polishing device

An airbag polishing and airbag technology, which is used in grinding/polishing equipment, optical surface grinders, metal processing equipment, etc., can solve problems such as edge lift, edge effect, and different pressure, avoid winding, solve winding problems, The effect of balanced removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

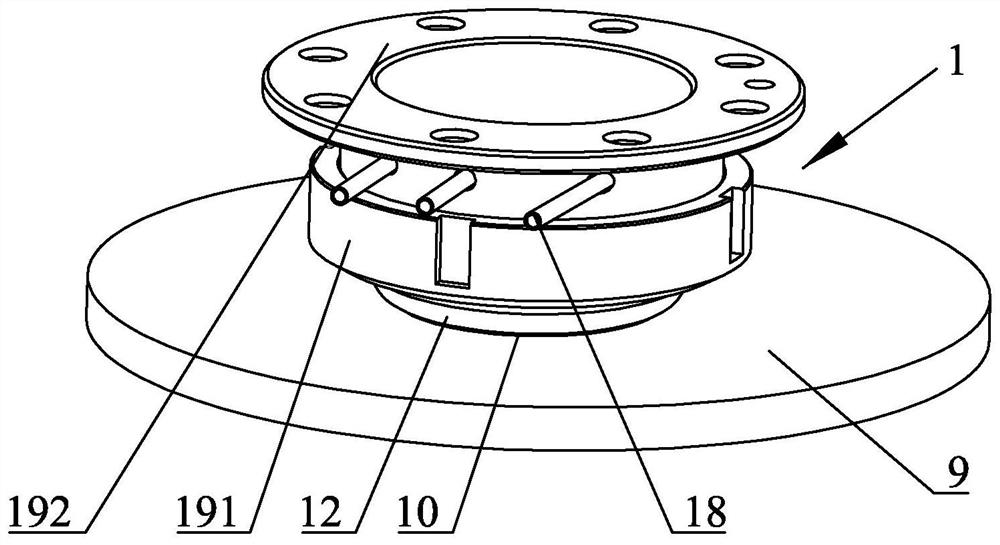

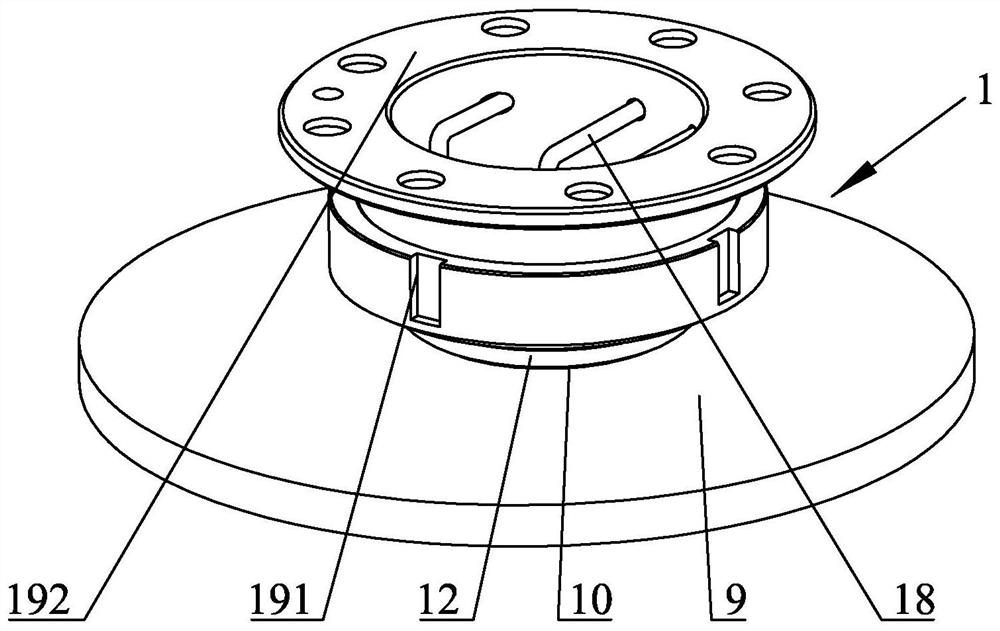

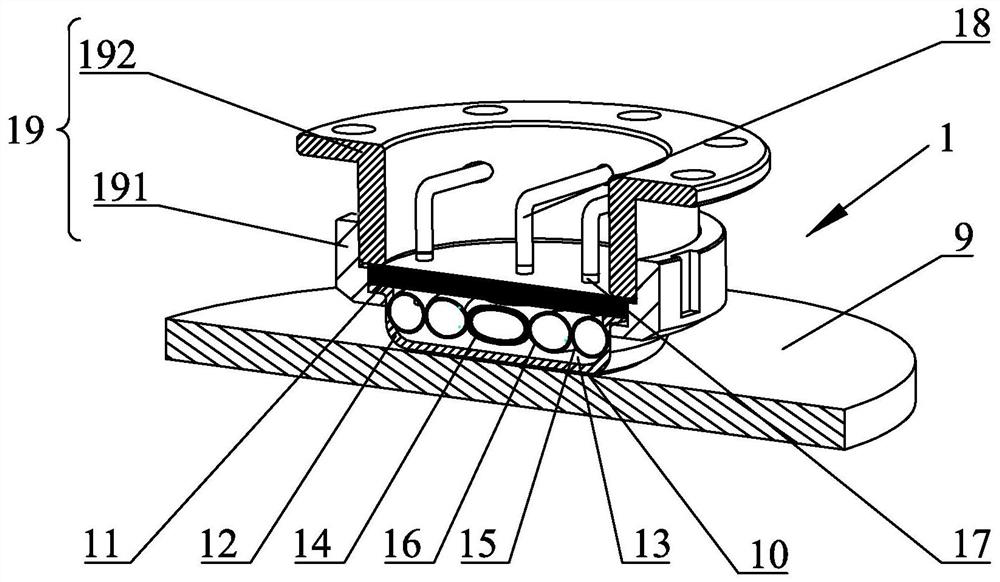

[0045] What the present invention discloses is a kind of airbag polishing head mechanism that can regulate pressure in sections, such as Figure 1-7 Shown is a preferred embodiment of the polishing head mechanism of the present invention. The polishing head mechanism 1 includes a back plate 11, a diaphragm 12 and an air bag group consisting of at least two air bags. in:

[0046] The back plate 11 is connected with the surroundings of the diaphragm 12, specifically by screws, and a sealed compartment 13 is formed between them. The diaphragm 12 is pot-shaped, and its bottom is a circular plane. The material of the back plate 11 can be 45# steel, and the material of the diaphragm 12 can be a sealing diaphragm made of rubber.

[0047] Each airbag of the airbag group is concentrically arranged in the sealed compartment 13, and the airb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com