A water chestnut shell opening device for water chestnut processing and production

A water chestnut and outer box technology, applied in the direction of shelling, application, pod removal, etc., can solve the problems of strange shape of water chestnut, slow opening speed, danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

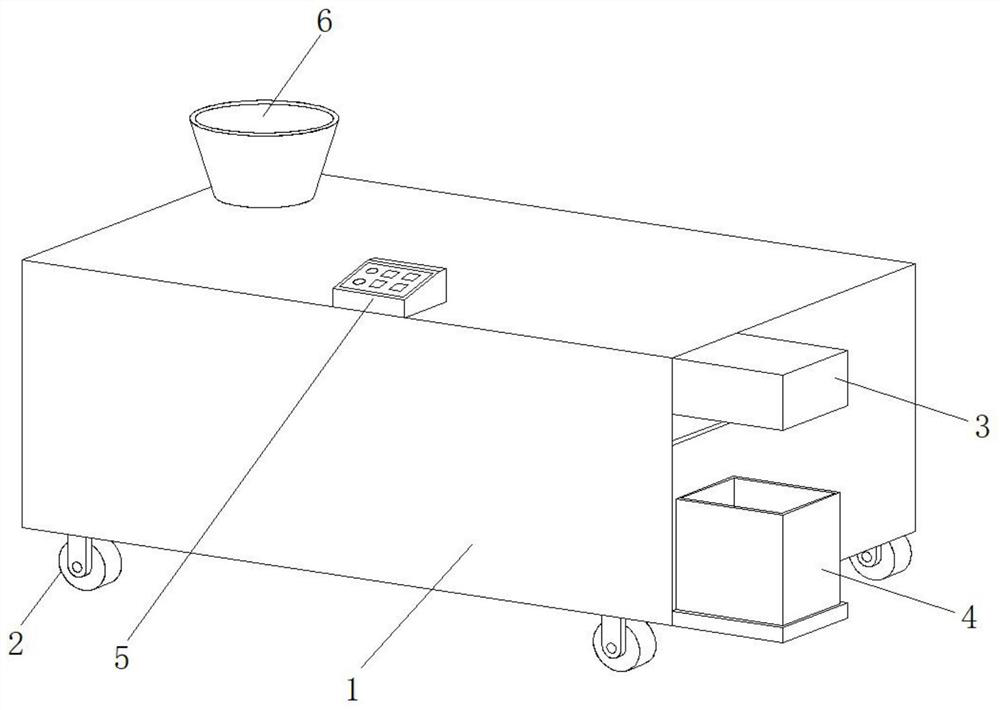

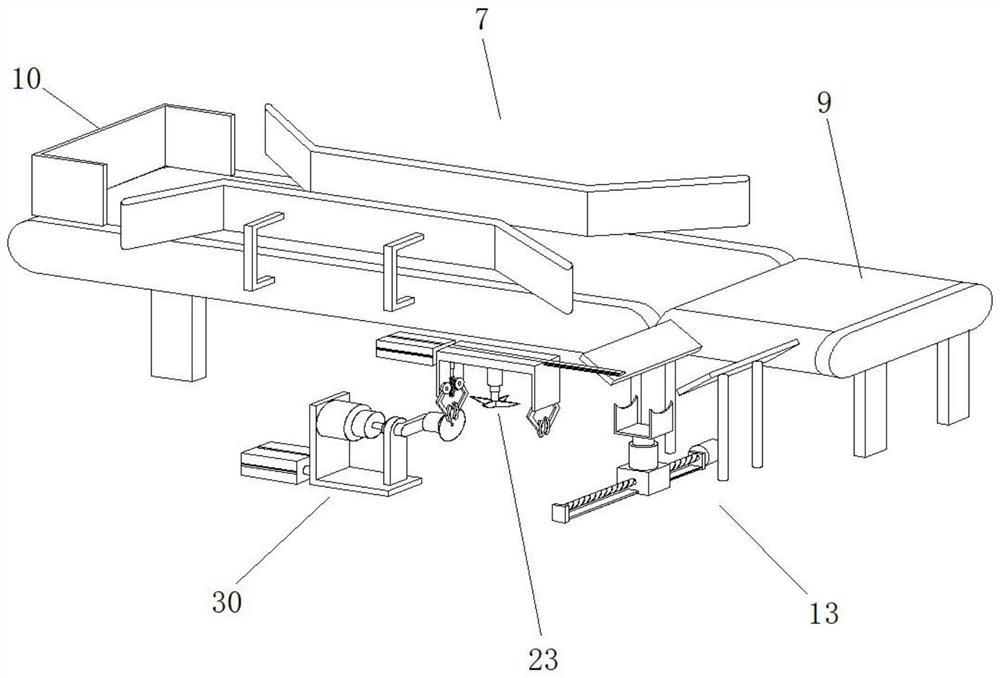

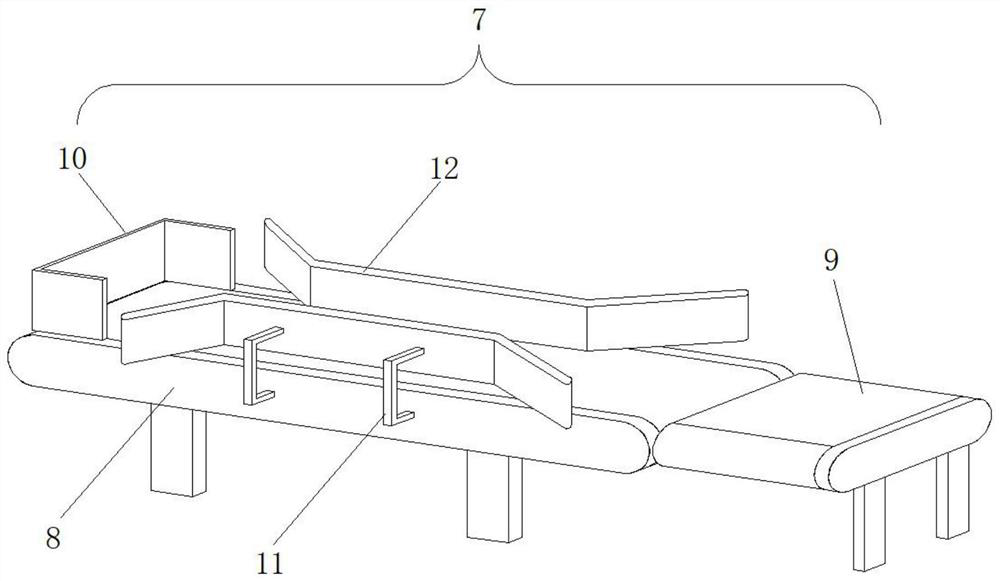

[0034] see Figure 1-3, a water chestnut shell opening device for water chestnut processing and production, comprising an outer box body 1, universal wheels 2 are fixedly installed at the four corners of the bottom of the outer box body 1, and one end top of the outer box body 1 is provided with A discharge port 3, the bottom of the discharge port 3 is provided with a collection box 4, a control switch 5 is fixedly installed on one side of the top of the outer box body 1, and the top end of the outer box body 1 is provided with a feed port 6, the inside of the outer box 1 is fixed with a feeding device 7 arranged below the feeding port 6, the feeding device 7 includes a guide transmission mechanism 8 and a steering transmission mechanism 9, and the guide transmission mechanism 8 is located at the inlet One end below the feed port 6 is fixedly equipped with a fence plate 10, and both sides of the guide transmission mechanism 8 are fixedly connected with mutually symmetrical gui...

Embodiment example 2

[0044] Specifically, the transmission direction of the guide transmission mechanism 8 is from the feed port 6 to the discharge port 3, and the transmission direction of the steering transmission mechanism 9 is perpendicular to the guide transmission mechanism 8 and points to the direction of the feeding device 13. The distance between the two supporting plates 14 that are inclined in a V shape is slightly greater than the width of the U-shaped lifting plate 21, and the straight lines where the arc-shaped notches 22 on both sides of the U-shaped lifting plate 21 are parallel In the direction of the guide transmission mechanism 8; both ends of the ball screw 17 and the first slide rail 18 are rotatably mounted on the base 39 fixed on the inner lower wall of the outer box 1.

[0045] The guide transmission mechanism 8 for horizontal transmission cooperates with the steering transmission mechanism 9 for vertical transmission to realize the horizontal output of water chestnut to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com