Suturing assembly of anastomat and anastomat

A stapler and component technology, applied in the field of medical suture equipment, can solve the problems of secondary injury of patients, suture deviation, stapler damage, etc., and achieve the effect of avoiding stapler damage and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

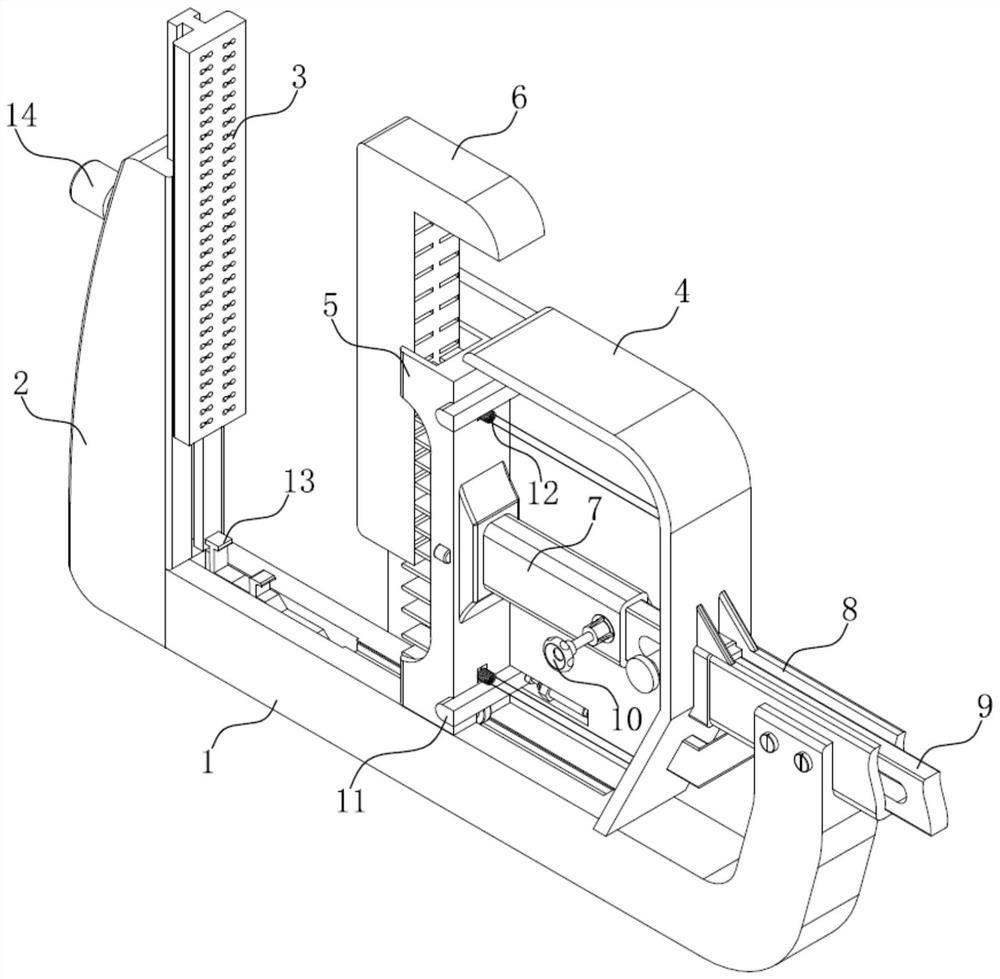

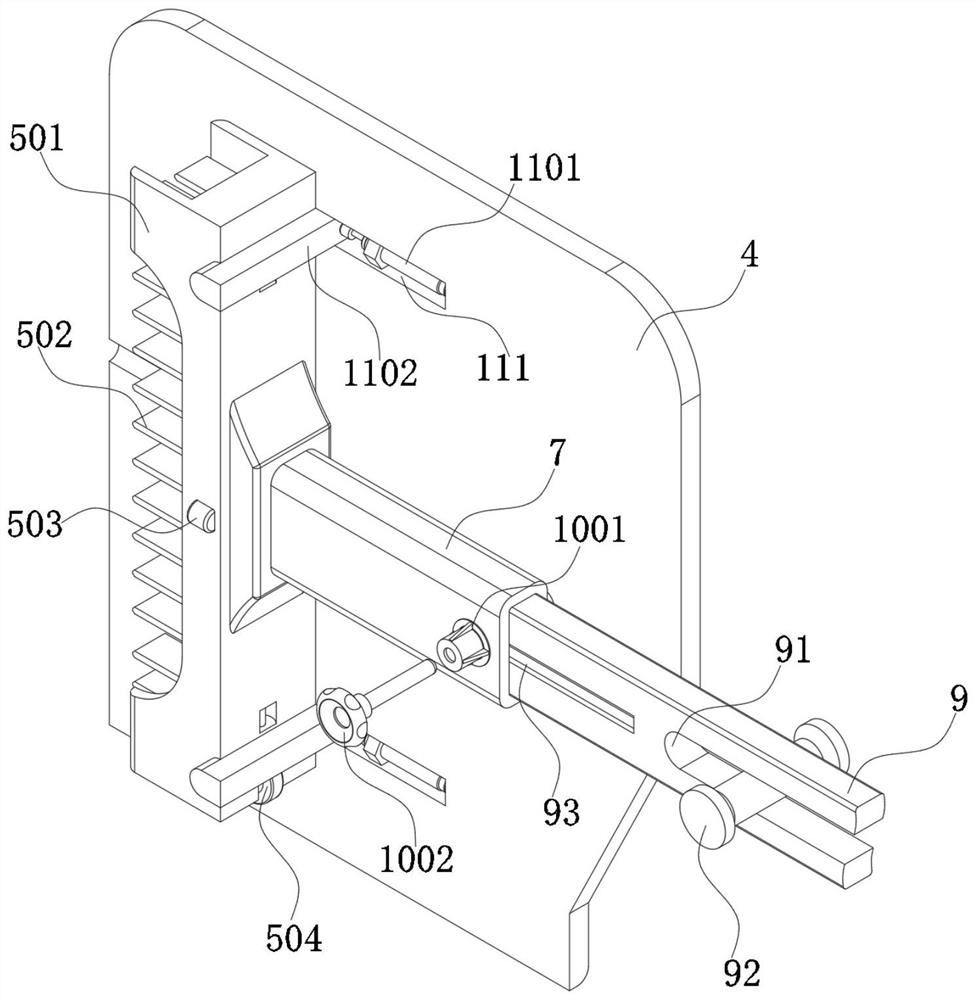

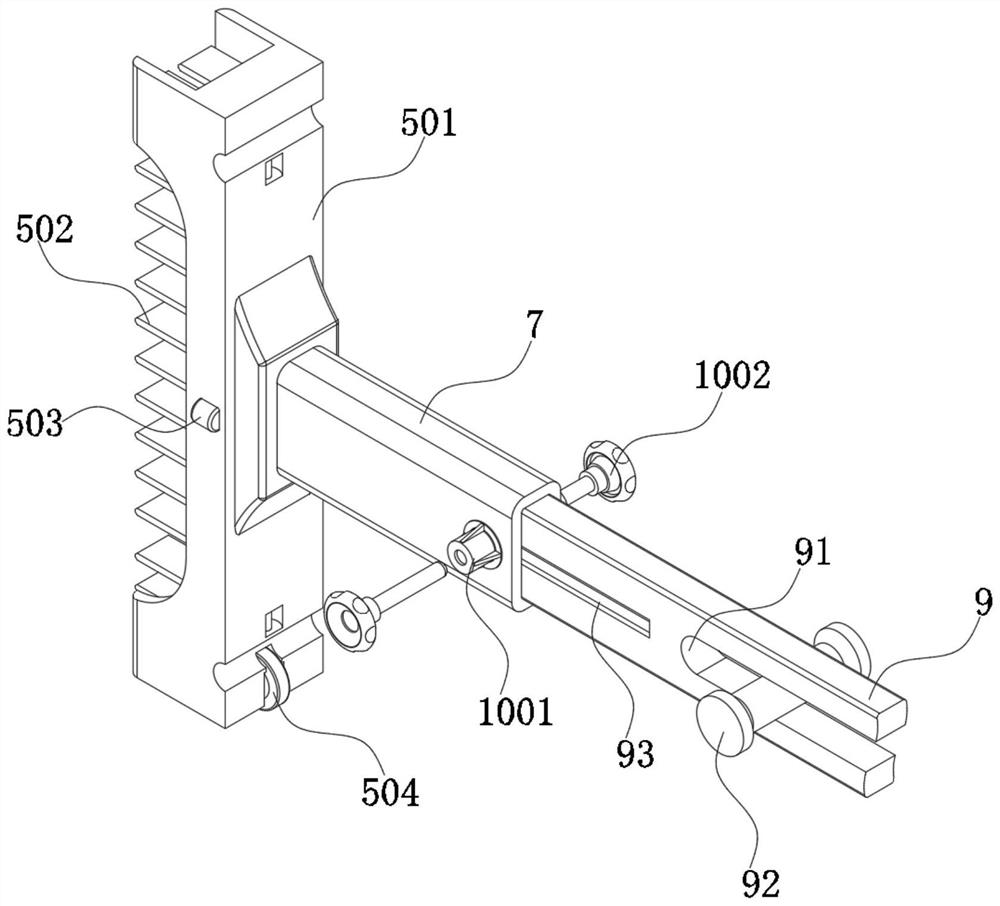

[0033] see Figure 1 to Figure 8 , the present invention provides a technical solution:

[0034] A suturing assembly of a stapler, comprising a mounting base 1, an anvil base 2, an anvil assembly 3, a housing 4, a nail pushing assembly 5, a staple bin 6, a telescopic bin 7, a bracket assembly 8, a push rod 9, and a screw assembly 10 , limit assembly 11, back-moving spring 12, isolation assembly 13 and fixed screw rod 14, wherein:

[0035] One end of the mounting seat 1 is equipped with a nail anvil block 2, the nail anvil assembly 3 is installed on the nail anvil block 2, the upper end surface of the mounting seat 1 is fixed with a shell 4, and the mounting seat 1 is provided with a push A nail assembly 5, the nail pusher assembly 5 includes a nail pusher bracket 501 and a nail pusher rod 502, a nail pusher rod 502 is installed in the nail pusher bracket 501, and the nail pusher rod 502 is used to push a staple, and the nail pusher assembly 5, a staple bin 6 is installed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com