Ring opening arrangement polishing and shaping collection equipment

A collection equipment and grinding machine technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of low grinding efficiency, high labor cost, poor operation stability, etc., to achieve high-quality and high-efficiency grinding, The effect of improving arrangement efficiency and saving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

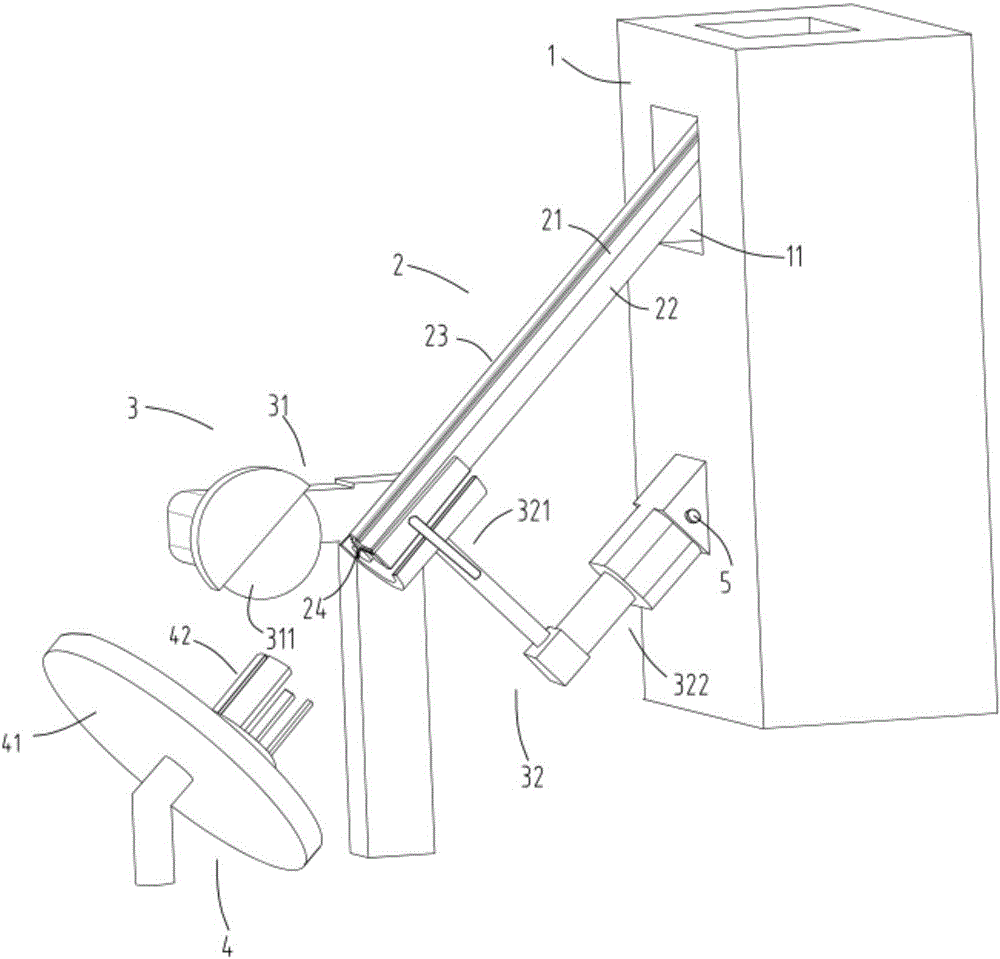

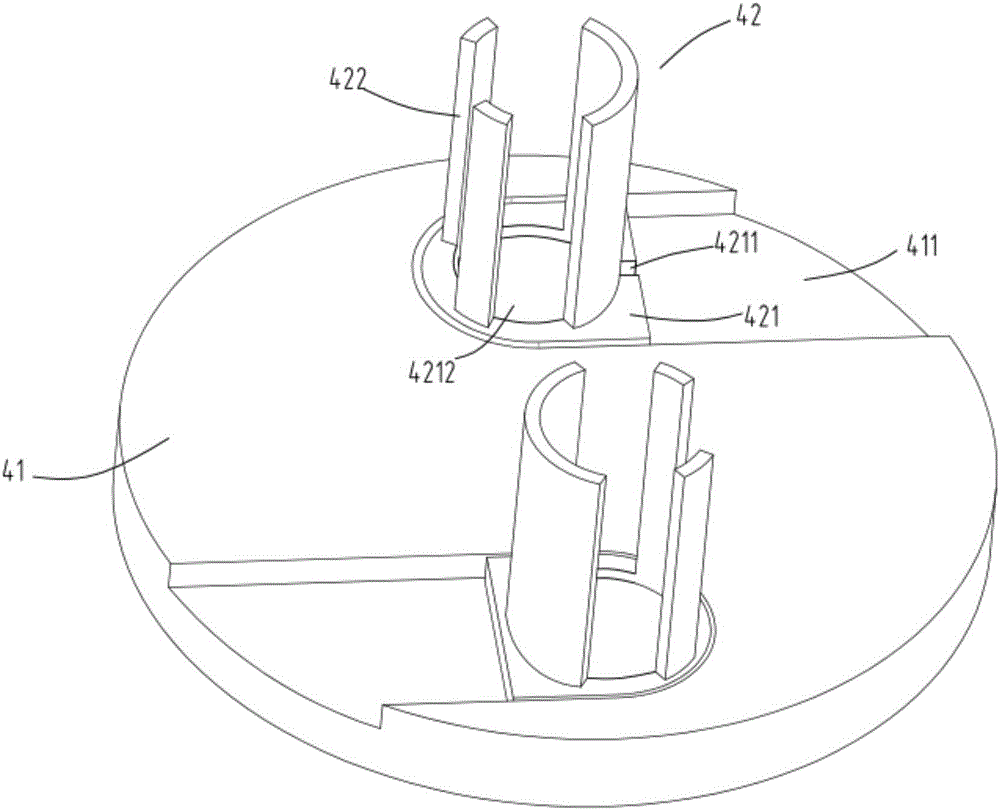

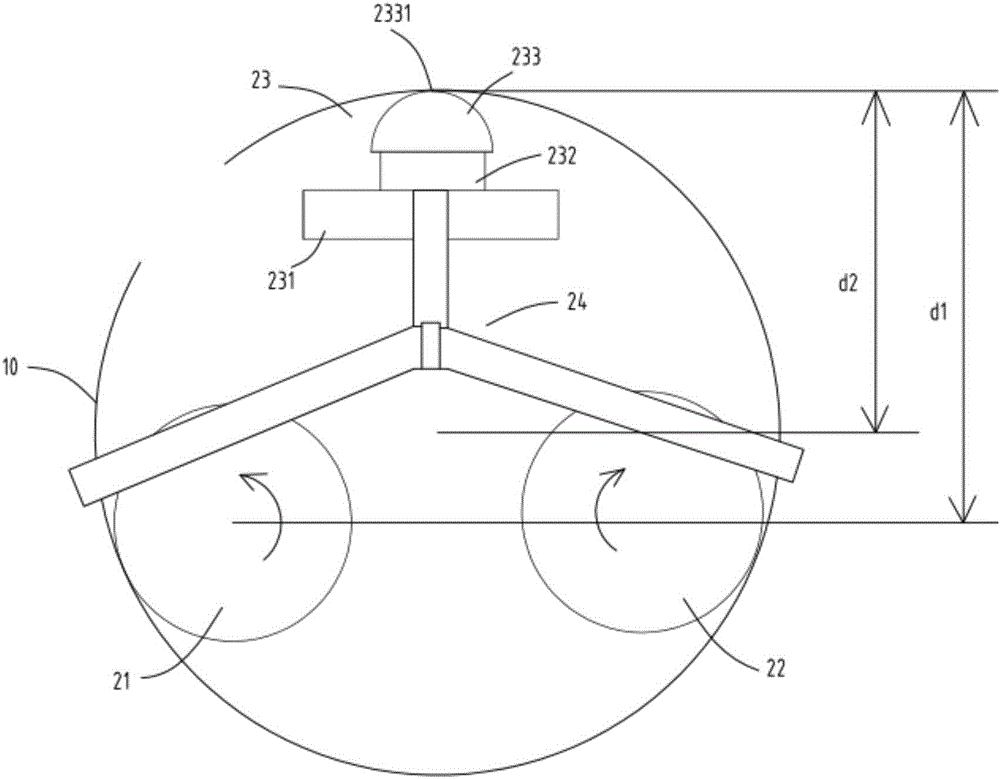

[0028] figure 1 It is a structural schematic diagram of a material bar rotation arrangement grinding breach equipment, figure 2 Schematic diagram of the structure of the stereotyped collection device, image 3 It is a schematic diagram of the structure of the automatic alignment device when the piston ring is hung on the rib a, Figure 4 It is a schematic diagram of the structure of the automatic arrangement device when the piston ring is hung on the pallet, Figure 5 Schematic diagram of the structure of the rotation arrangement device. Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5As shown, a ring opening arrangement grinding and shaping collection equipment includes a chipping machine 1, an automatic alignment device 2, a grinding device 3 and a shaped collection device 4; the automatic alignment device 2 is arranged at the material outlet 11 of the chipping machine 1 place, used to neatly arrange the broken piston rings 10 in a straight line at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com