A kind of ring opening toggle arrangement and grinding step equipment

An automatic arrangement and step technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of piston ring damage, high failure rate, and large manpower consumption of piston rings, and achieve simple structure and power saving , the effect of high arrangement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

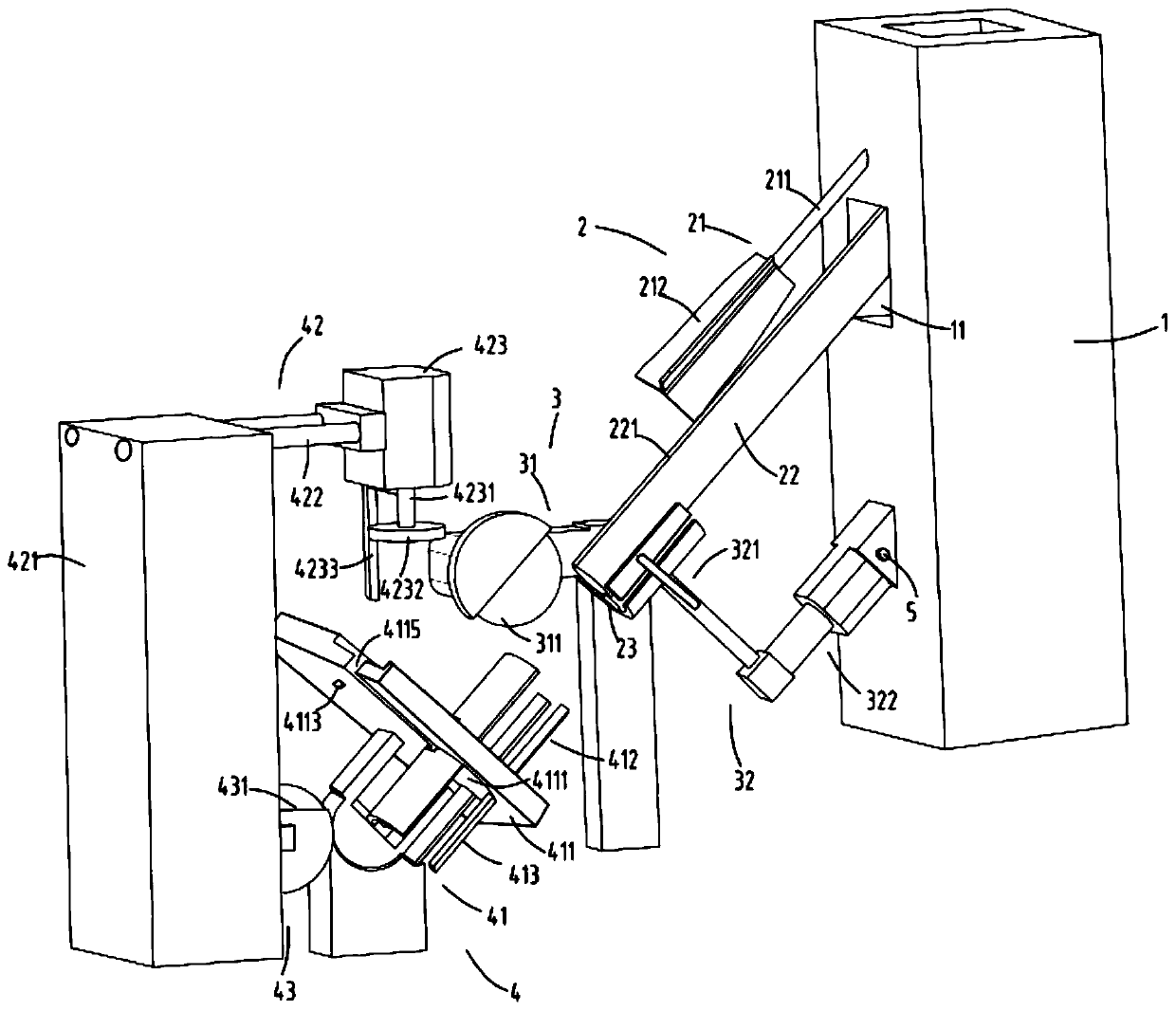

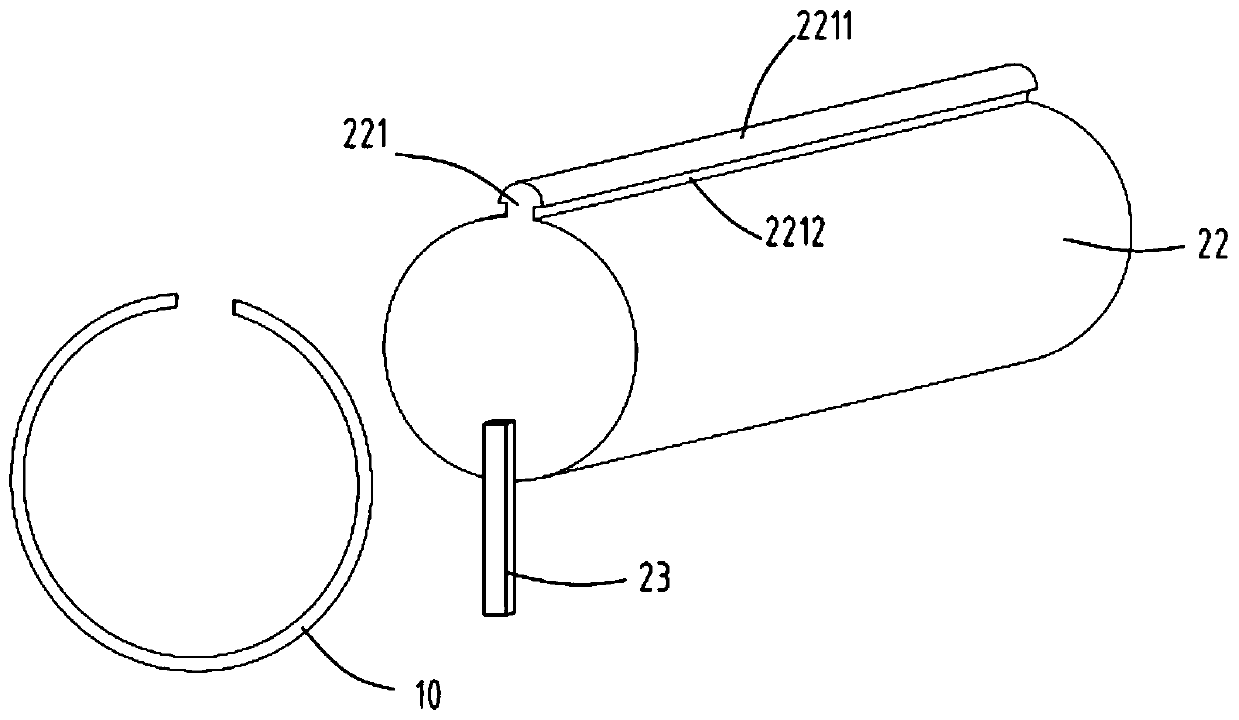

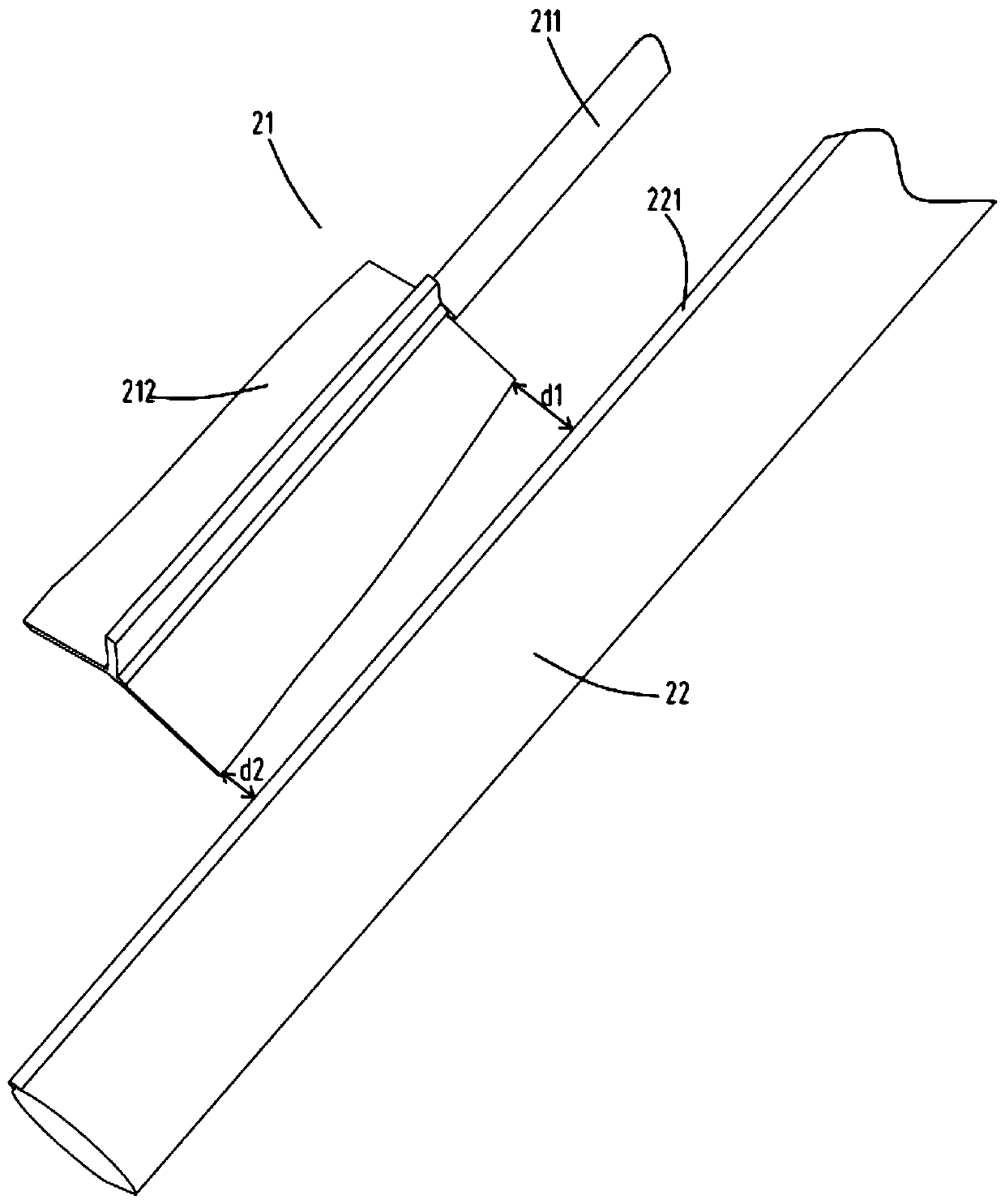

[0032] figure 1 It is a schematic diagram of the structure of a kind of ring opening toggle arrangement and grinding step equipment, figure 2 is a schematic diagram of the rod, image 3 A schematic diagram of the automatic arrangement device, Figure 4 A cross-sectional schematic diagram of the automatic arrangement device, Figure 5 It is a schematic diagram of the structure of the open grinding step part, Figure 6 It is a schematic diagram of the structure of the fixed plate and the turning device, Figure 7 It is a schematic diagram of the processed piston ring structure. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7As shown in the figure, a kind of ring opening toggle arrangement and grinding step equipment includes a breaching machine 1, an automatic arrangement device 2, an opening grinding device 3 and an opening grinding step part 4; The material outlet 11 is used to neatly arrange the piston rings 10 that have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com