Ring opening, bidirectional stirring, arranging and grinding device

An automatic arrangement and grinding machine technology, which is applied in the direction of automatic grinding control devices, grinding machines, grinding workpiece supports, etc., can solve the problems that piston ring openings cannot be polished in batches, piston rings cannot be automatically arranged, and the arrangement effect is not good. , to achieve the effect of simple structure, power saving and high efficiency grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

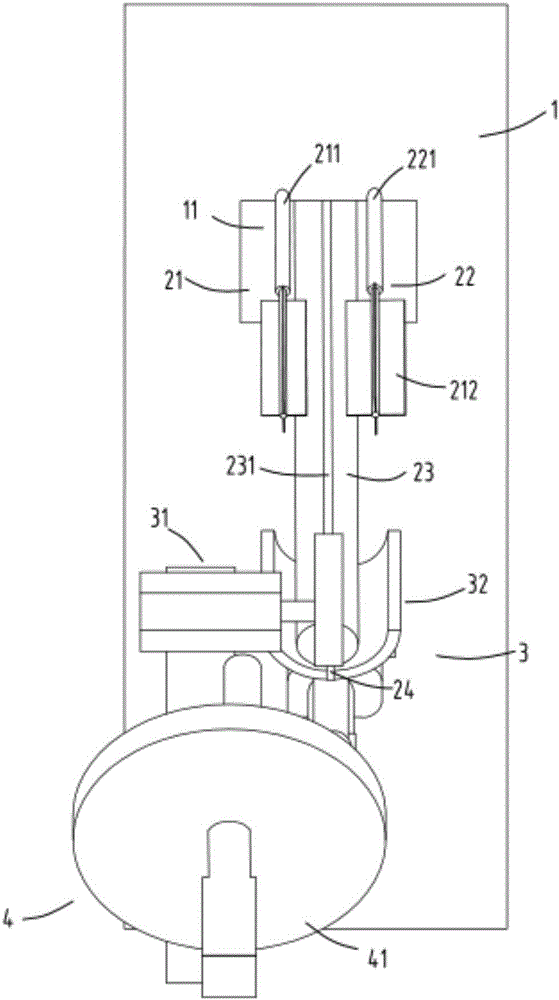

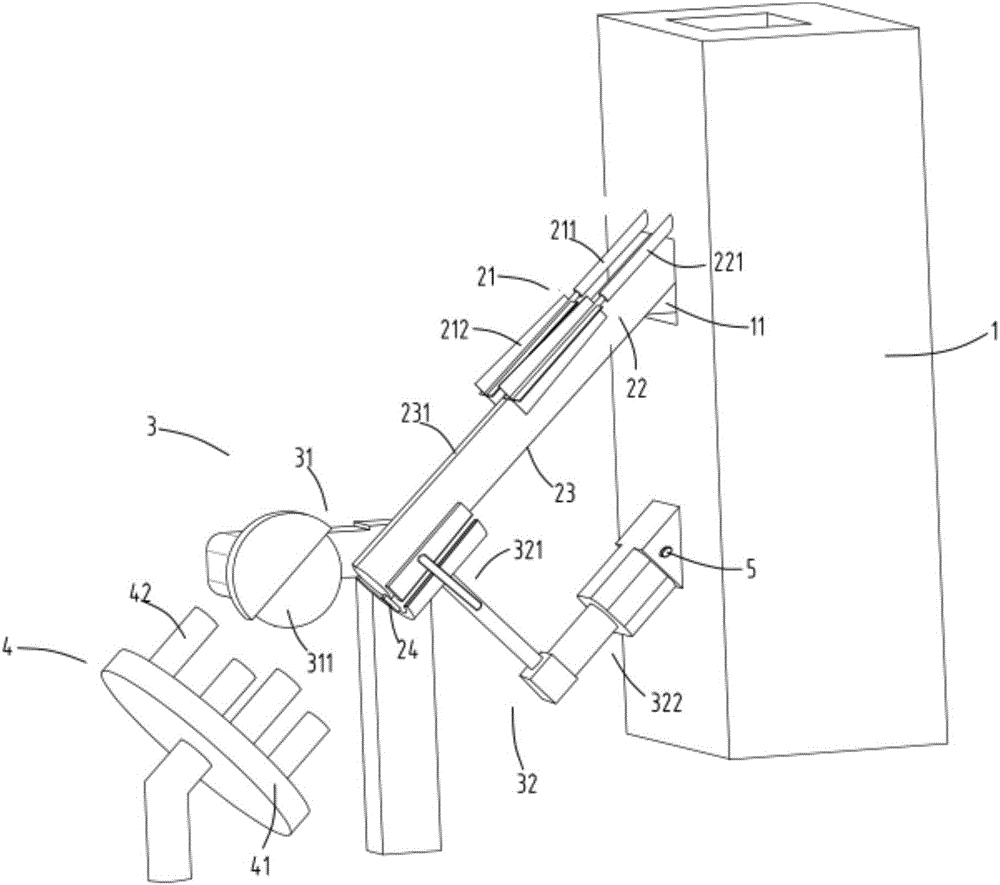

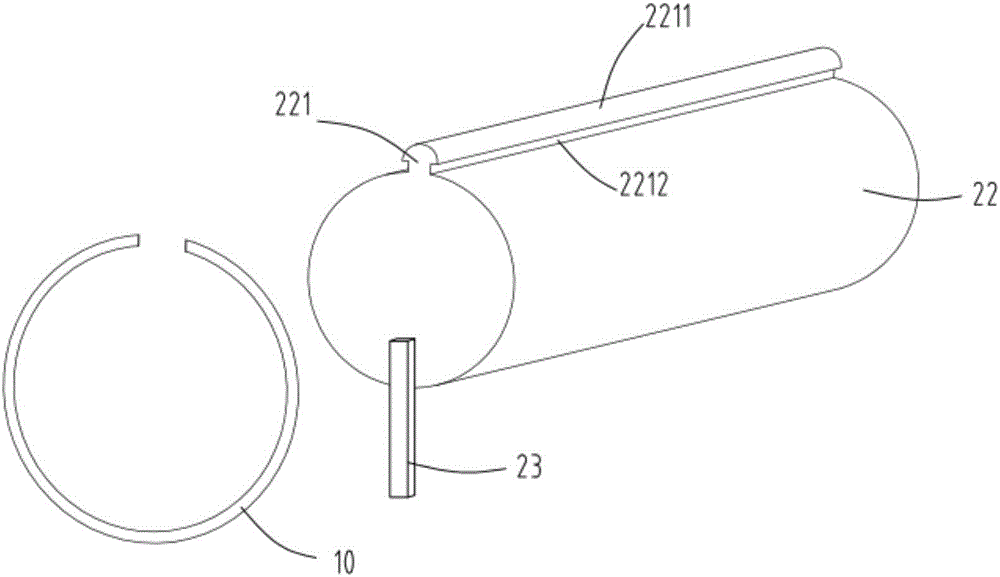

[0028] figure 1 It is a schematic top view of a ring opening two-way toggle arrangement and polishing device, figure 2 It is a schematic diagram of the three-dimensional structure of a ring opening two-way toggle arrangement and polishing device, image 3 It is a schematic diagram of the material rod structure of a ring-opening bidirectional dial arrangement and grinding device, Figure 4 It is a schematic diagram of the structure of an automatic arrangement device of a ring opening bidirectional dial arrangement and polishing device, Figure 5 It is a cross-sectional schematic diagram of an automatic arrangement device of a ring opening bidirectional dial arrangement and polishing device. Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a ring-opening two-way toggle arrangement and polishing device includes a breaker 1, an automatic alignment device 2, a polishing device 3, and a collecting tray 4; the automatic alignment device 2 is arranged at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com