Ring shifting arranging, polishing and forming collecting equipment

A collection equipment and automatic arrangement technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of large manpower consumption, complex structure, low efficiency, etc., and achieve high-quality and high-efficiency grinding and arrangement The effect of high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

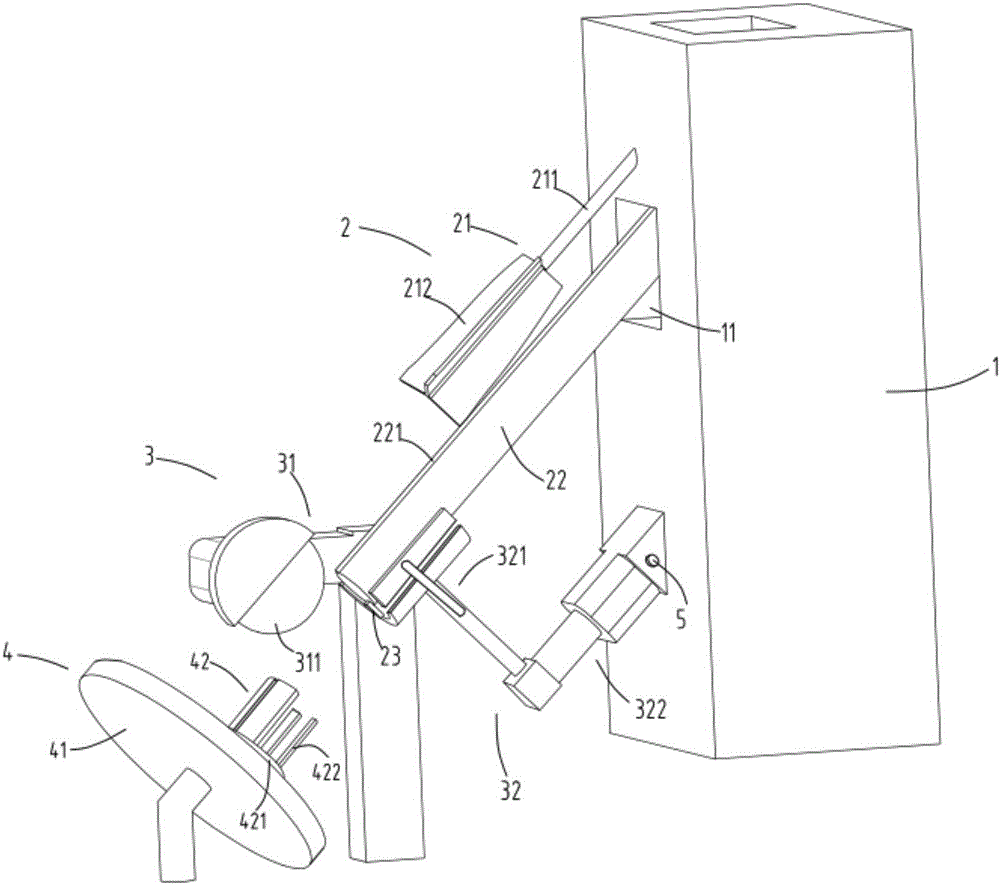

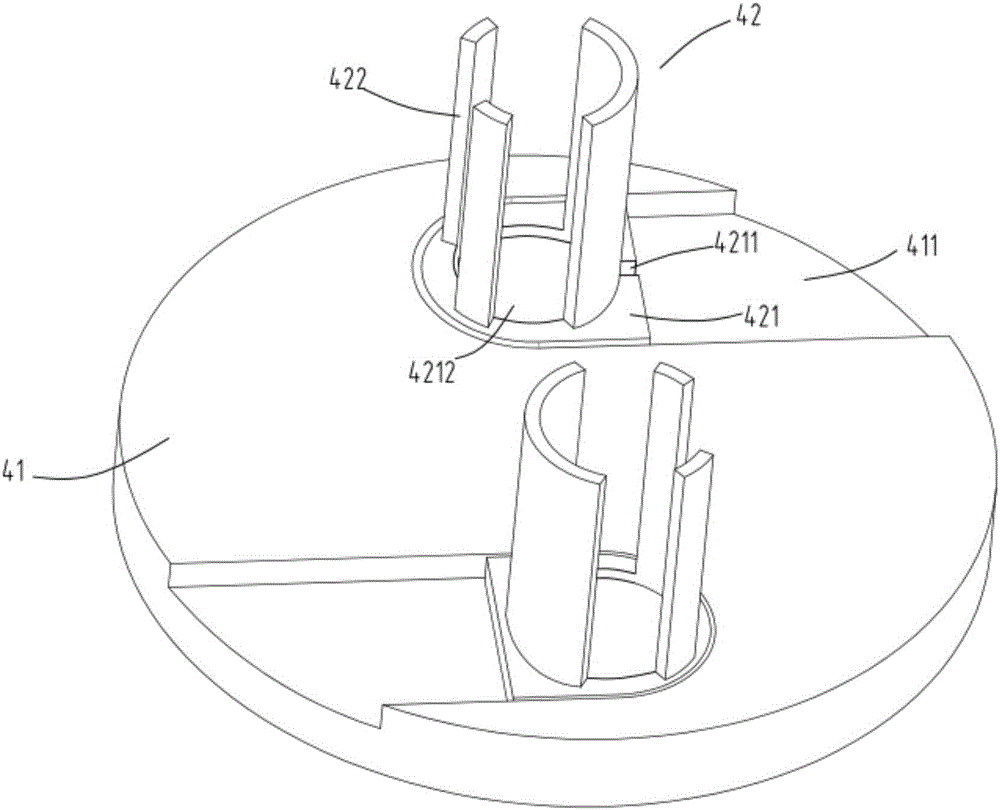

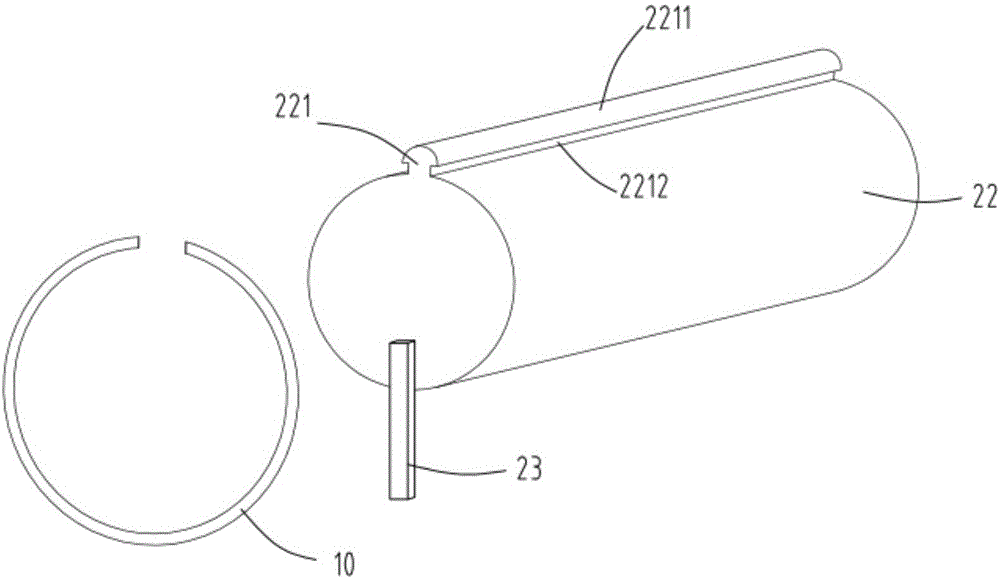

[0028] figure 1 It is a structural schematic diagram of a kind of ring toggle arrangement grinding and shaping collection equipment, figure 2 Schematic diagram of the structure of the stereotyped collection device, image 3 is a schematic diagram of the rod, Figure 4 A schematic diagram of the automatic arrangement device, Figure 5 A cross-sectional schematic diagram of the automatic arrangement device. Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown in the figure, a ring toggle arrangement grinding and shaping collection equipment includes a splitting machine 1, an automatic alignment device 2, a polishing device 3 and a shaped collection device 4; the automatic alignment device 2 is arranged at the material outlet of the splitting machine 1 11 places, which are used to arrange the piston rings 10 that have been breached neatly in a line at the breach; Grinding; the sizing collection device 4 is arranged at the rear end of the grinding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com