A large battery installation

A battery installation device and large-scale technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of large battery volume and difficult screwing into the wall, etc., and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

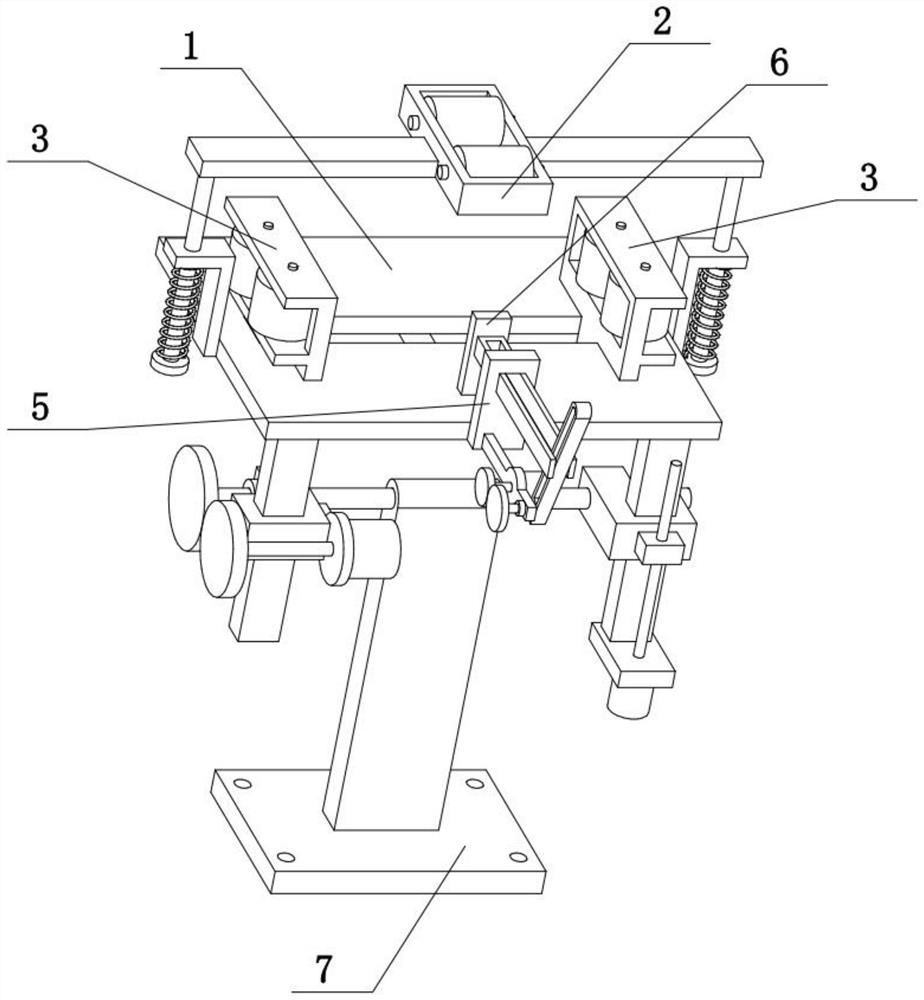

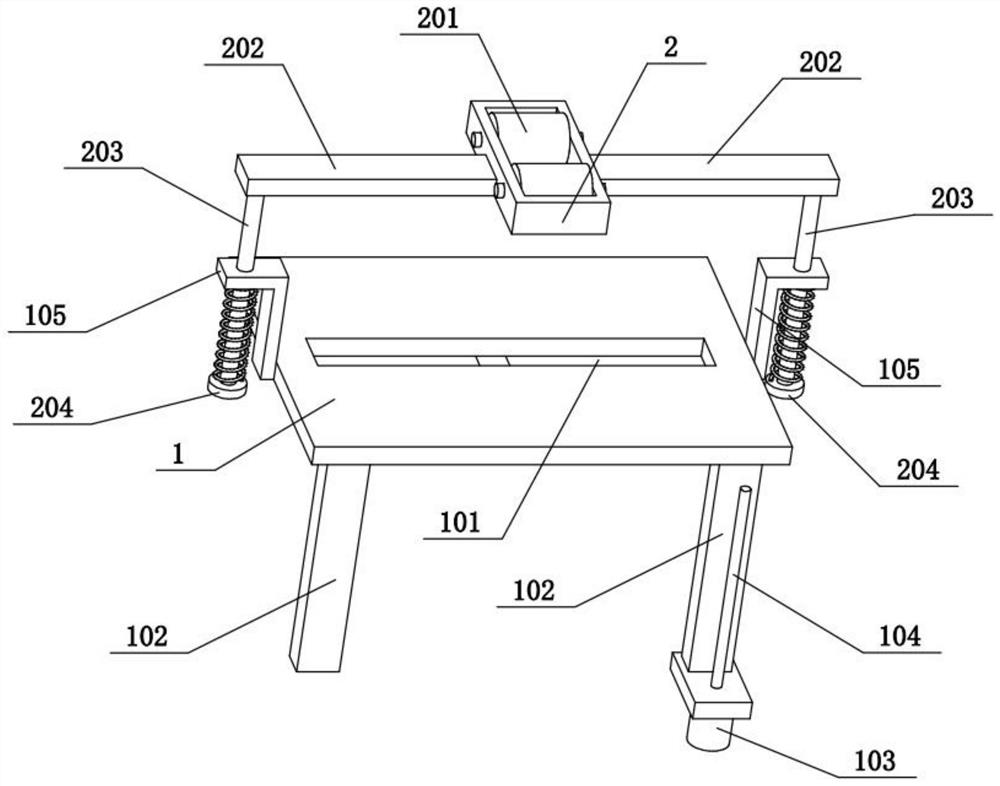

[0034] Combine below Figure 1-9 Describe this embodiment, the present invention relates to a mounting device, more specifically a large battery mounting device, including a flat plate 1, a horizontal slide hole 101, a clip seat 3, a side slot 301, a side wheel 302, and a stop pin 303 , convex plate 304, sliding seat 5, push plate 6 and push rod 601, the present invention can lift the battery with larger volume on the high place, is convenient to screw the screw on the battery into the wall, and is convenient for the installation of larger battery .

[0035] The flat plate 1 is provided with a horizontal sliding hole 101, the middle part of the front end of the flat plate 1 is fixedly connected with a sliding seat 5, the sliding seat 5 is slidably connected with a push rod 601, and the rear end of the push rod 601 is fixedly connected with a push plate 6, and the clamp seat 3. There are two on the left and right. The middle parts of the lower ends of the two clamping seats 3 ...

specific Embodiment approach 2

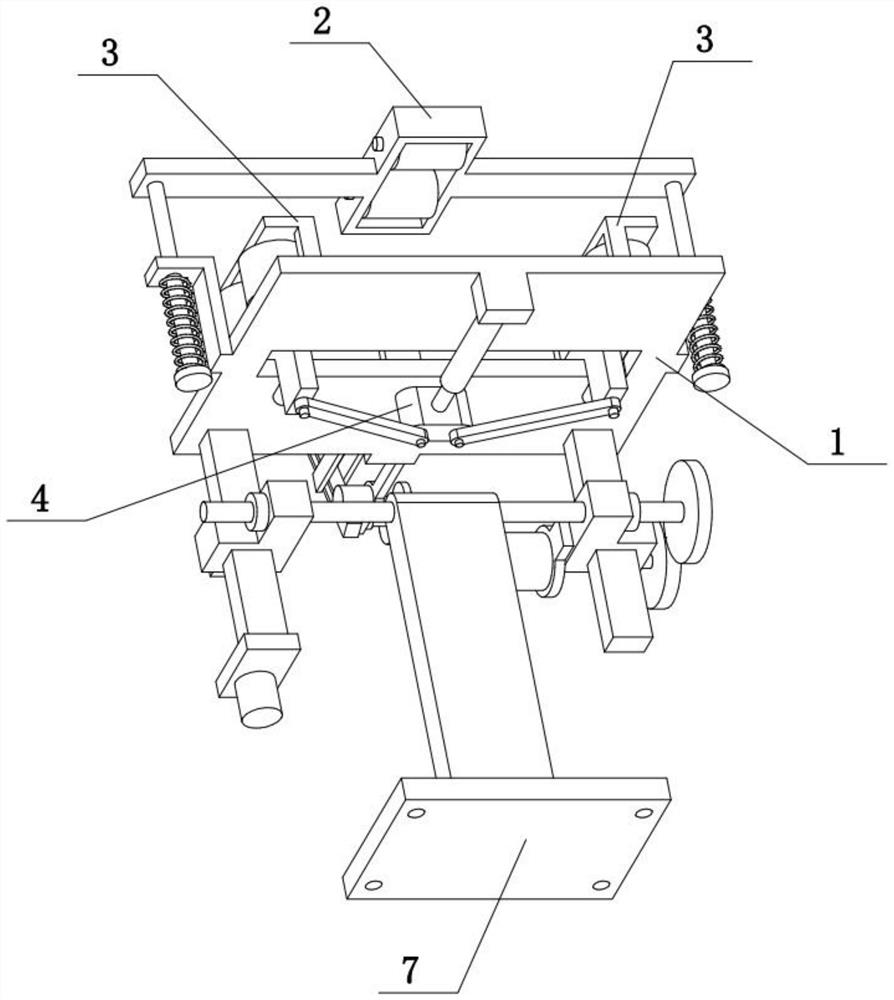

[0037] Combine below Figure 1-9To illustrate this embodiment, the large-scale battery installation device also includes a convex seat 106, an electric telescopic rod 107, a middle block 4 and an equal-length rod 401. The side is fixedly connected with an electric telescopic rod 107, and the left and right ends of the middle block 4 are all hingedly connected with an equal-length rod 401, and the other ends of the two equal-length rods 401 are respectively hingedly connected to the bottom of two convex plates 304, and the electric telescopic rod 107 The front end is fixedly connected on the middle block 4. When the electric telescopic rod 107 is stretched or shortened, it can drive the middle block 4 to slide forward or backward, and when the middle block 4 slides forward or backward, the two equal-length rods 401 can respectively drive the two convex plates 304 to approach each other or away, and then drive the two clamping seats 3 to approach or move away from each other, a...

specific Embodiment approach 3

[0039] Combine below Figure 1-9 To illustrate this embodiment, the large-scale battery installation device also includes a front extension rod 501, a motor II502, a gear I503, a short cylinder 602, a short cylinder chute 603, a chute rod 604, a short shaft 605, and a gear II606. The front side is fixedly connected with the front extension rod 501, the front extension rod 501 is fixedly connected with the motor II502, the output shaft of the motor II502 is fixedly connected with the gear I503, the chute rod 604 is provided with a short cylindrical chute 603, and the chute rod 604 The lower end of the shaft 605 is fixedly connected with a short shaft 605, the short shaft 605 is rotatably connected to the front end of the front extension rod 501, the left end of the short shaft 605 is fixedly connected with a gear II606, the gear II606 is meshed with the gear I503 for transmission, and the front end of the push rod 601 is fixedly connected with a short shaft. The cylinder 602 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com