Automatic workpiece code spraying device and method

A coding and workpiece technology, applied in the direction of power transmission device, printing device, printing, etc., can solve the problems of poor stability and consistency of coding quality, large workpiece size and weight, and limited application range, etc., to achieve convenient automatic operation, High precision and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

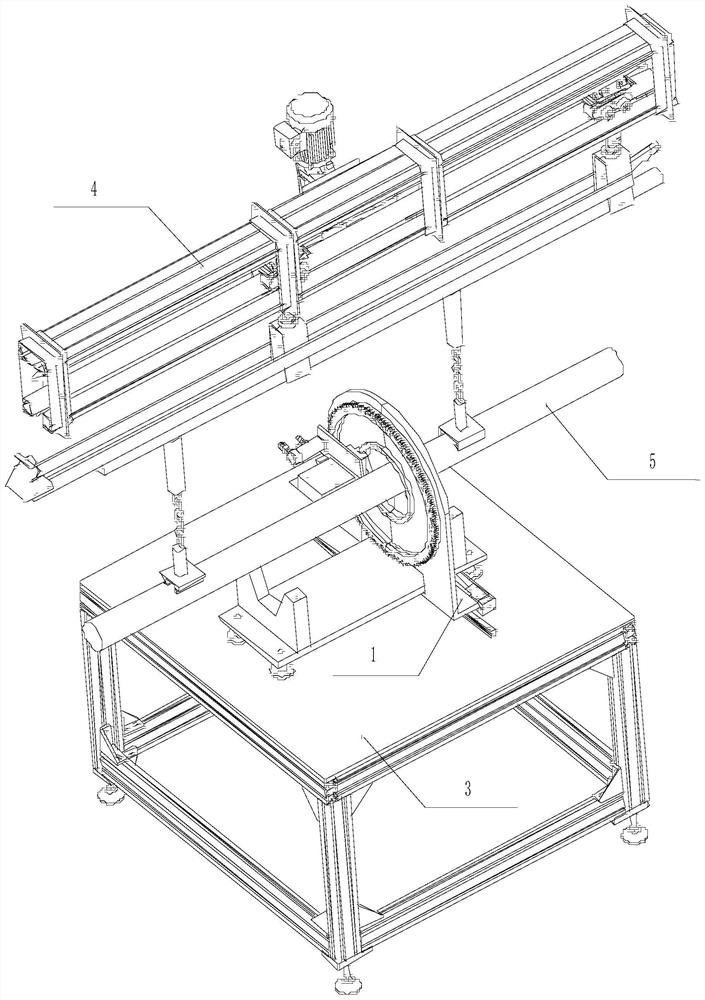

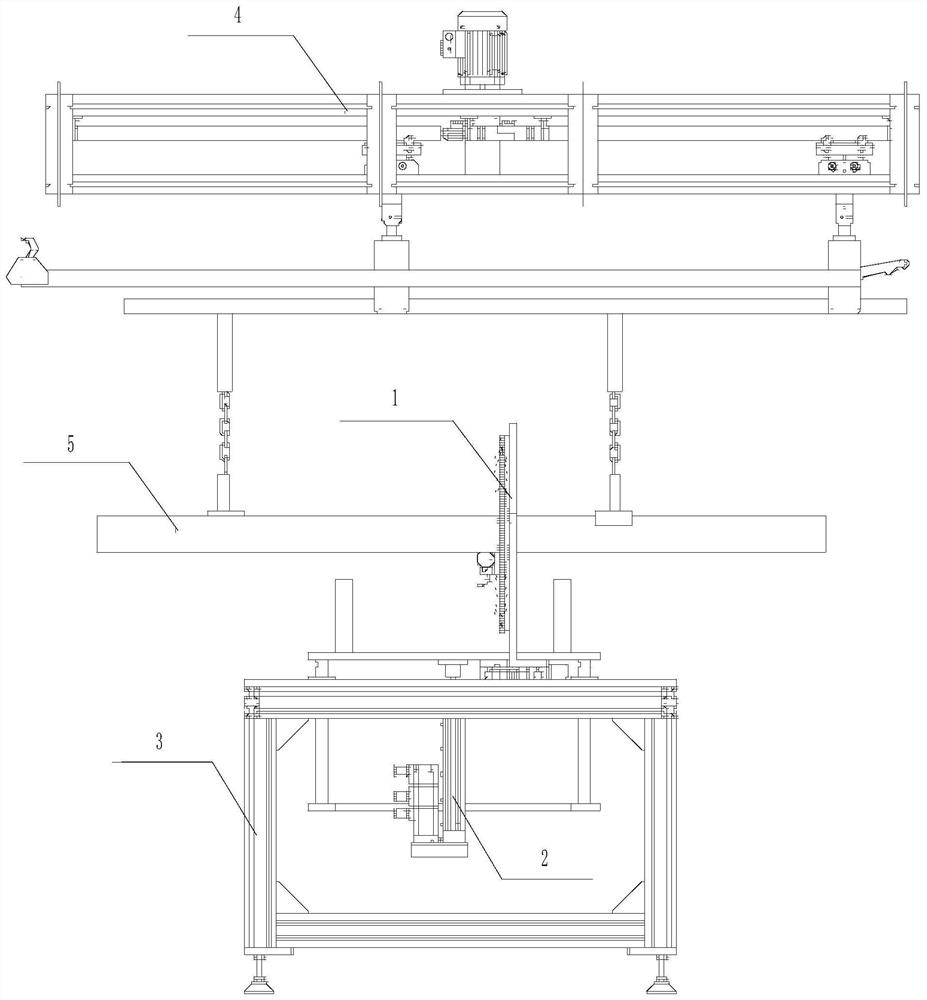

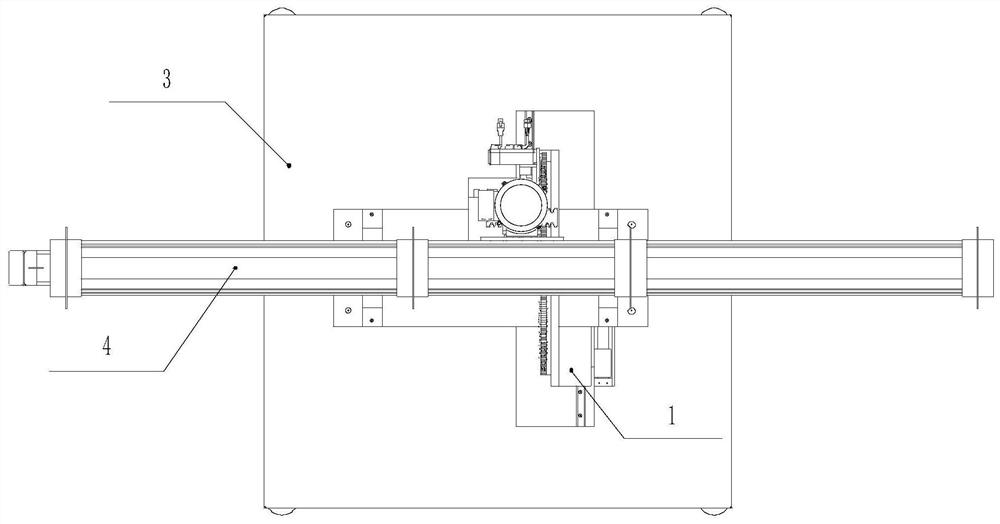

[0075] Figure 1 to Figure 14 A specific embodiment of the present invention is shown, an automatic coding device for cylindrical workpieces, including a coding unit 1, a lifting unit 2, a frame 3 and a conveying line unit 4,

[0076] like Figure 1 to Figure 3 As shown, the bottom of the frame 3 is equipped with adjustable legs, the lifting unit 2 is installed in the frame 3, the inkjet unit 1 is fixedly installed on the top surface of the frame 3, and the conveying line unit 4 is installed on the front of the inkjet unit 1. above,

[0077] like Figure 5 to Figure 9 As shown, the coding unit 1 includes a second linear guide rail pair 101, a second slide seat 102, a turntable 103, a second half ring gear 104, a second fan-shaped guide rail 105, a first fan-shaped guide rail 106, a first half ring gear 107, The first sliding seat 108, the first linear guide pair 109, the jetting terminal 110, the adapter plate 111, the servo motor 112, the driving gear 113, the first rack 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com