Battery charging generator for vehicle

A generator and vehicle technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of multi-working hours, increase in the number of parts, increase the number of parts, etc., reduce the number of combined operations, reduce the number of parts, and reduce the number of parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

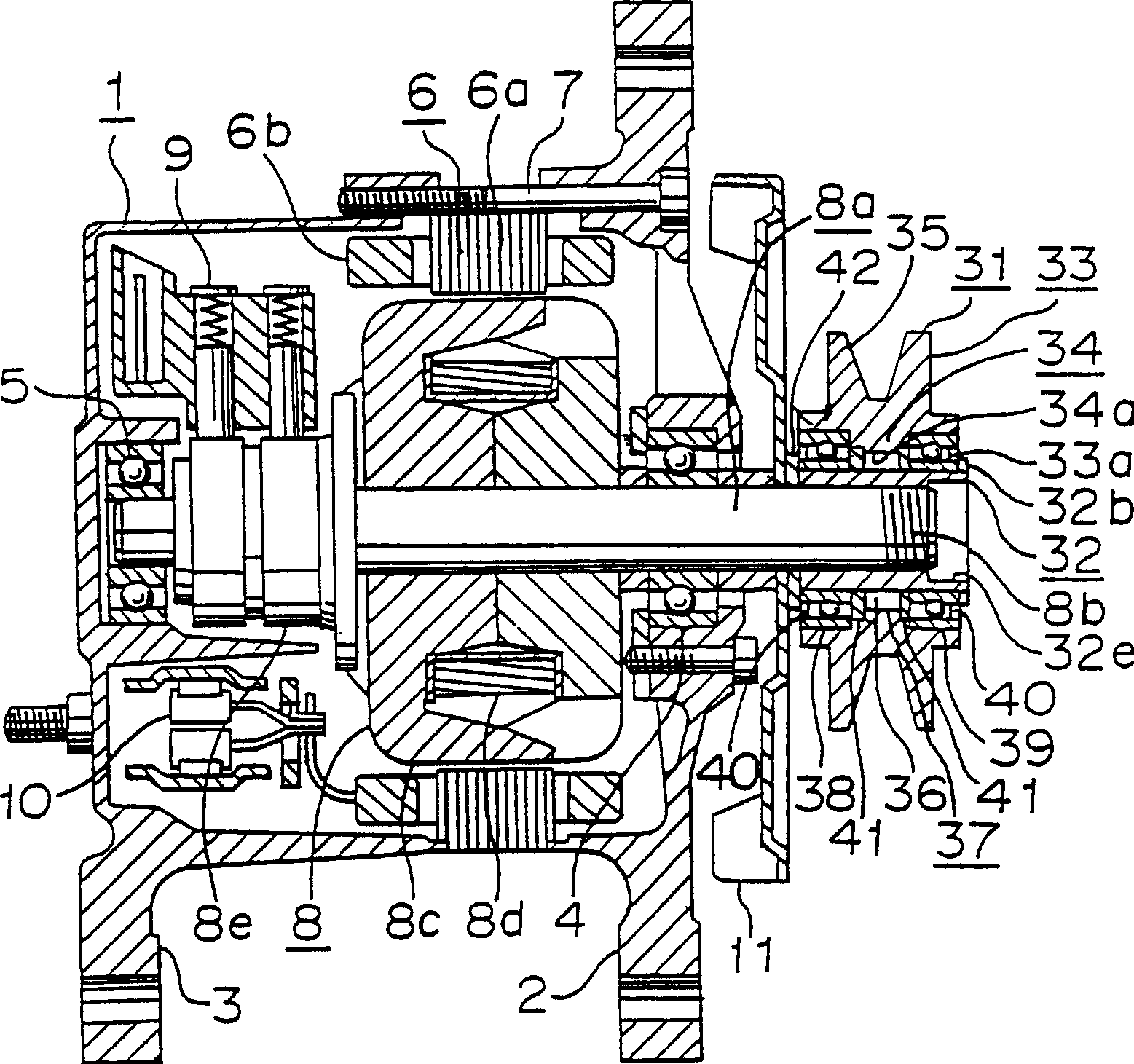

[0030] An embodiment of the present invention will be described below with reference to the drawings. figure 1 Is a view of the generator structure, figure 2 It is an enlarged view of the detailed structure of the inner sleeve of the one-way clutch. figure 1 with figure 2 In, the symbols 1 to 11 indicate the sum Figure 6 The same part as a traditional generator. Therefore, the corresponding parts use the same symbols, and the explanation is omitted in this article. However, the difference between this embodiment and the conventional example is that the rotor shaft 8a is shorter than that of a conventional generator, such as figure 1 Shown.

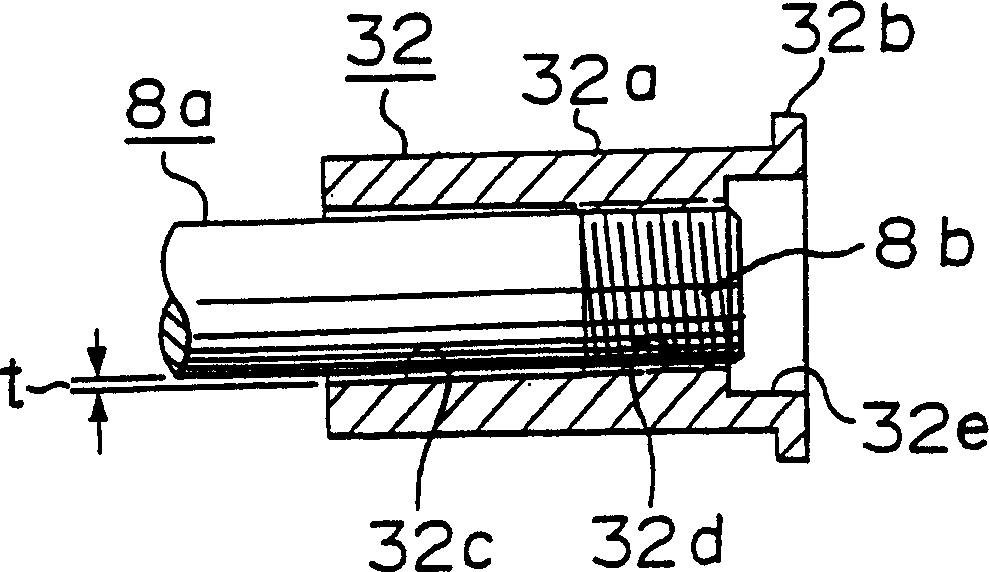

[0031] The number 31 is a one-way clutch, and its structure is as follows. 32 denotes a hollow cylindrical clutch inner sleeve, in which a flange 32b with a large outer diameter is provided at the right end of the outer circumferential portion 32a and constitutes a whole; such as figure 2 Shown. In addition, the right side of the hollow...

Embodiment 2

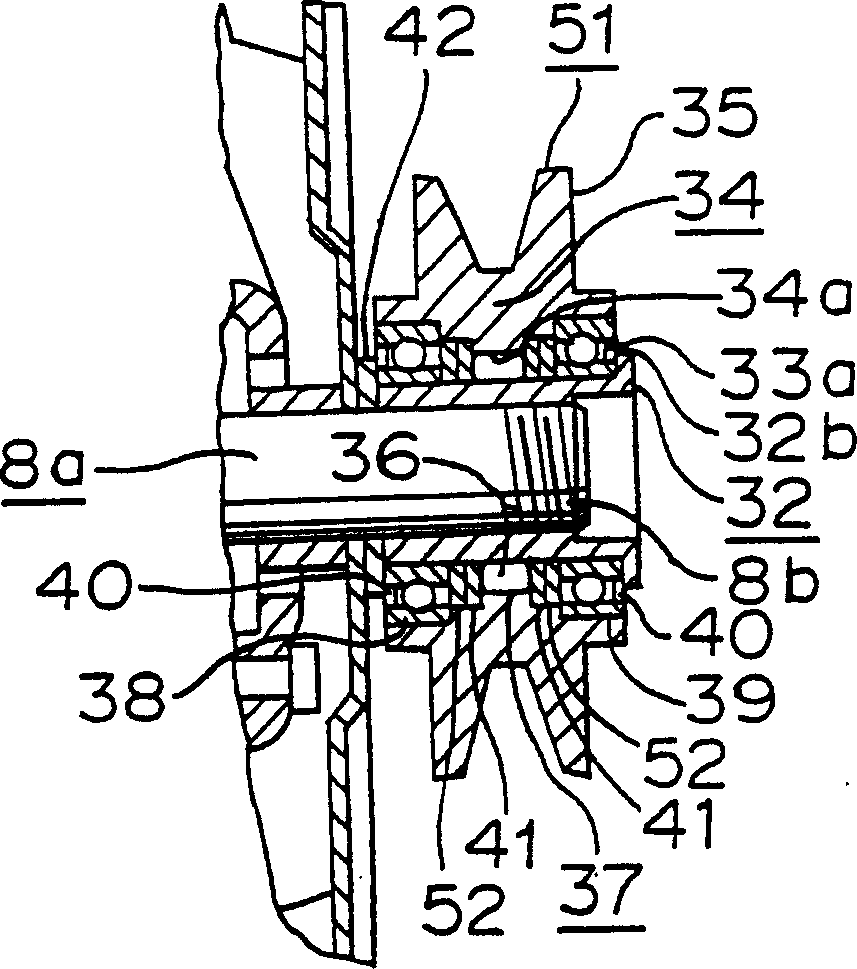

[0050] image 3 It is a structural view of another embodiment of the present invention. This embodiment will be explained below. Numeral 51 denotes a one-way clutch in which oil seals 52 are respectively installed between the ball bearings 38 and 39 and the engaging and disengaging parts 37 (clutch parts). Other structures and figure 1 The embodiment is the same.

[0051] The oil seal 52 separates the ball bearings 38 and 39 from the engaging and disengaging portion 37. In addition, considering the overall performance of the clutch, the rotating shaft 8a and the clutch inner sleeve 32 are installed with each other in a clearance fit. Therefore, this embodiment completely prevents the grease in the clutch components from flowing out of the gap, thereby achieving improved reliability.

[0052] In the case of using the oil seal 52, it is not necessary to pay special attention to the sealing performance between the bearing and the joining and separating parts. However, when differen...

Embodiment 3

[0055] Figure 4 It is a structural diagram of another embodiment of the present invention. In this embodiment, the rotor shaft also serves as a clutch inner sleeve. The structure is explained below.

[0056] The number 61 denotes a one-way clutch, in which the rotating shaft 62 also acts as the inner clutch 63. That is, the rotating shaft 62 has the function of the clutch inner sleeve 63. In this case, the rotating shaft 62 is provided with an external thread 62a, and the nut 64 is engaged with the external thread 62a. This method fastens the pulley with the one-way clutch to the rotating shaft 62. The material of the shaft 63 is forged steel. The part of the rotating shaft 63 facing the roller 36 on the outer circumference of the clutch inner sleeve 63 is induction hardened. Other structures and figure 1 The same as in Example 1.

[0057] By also serving as the rotating shaft 62 of the clutch inner sleeve 63, the deviation accuracy of the pulley 35 relative to the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com