Double-gas-path multi-separator oxygen production and supply system

An oxygen supply system and separator technology, which is applied in the direction of machines/engines, pump components, liquid variable capacity machinery, etc., can solve problems such as the decrease of oxygen concentration in the compartment, the threat to the life safety of passengers, and the power supply of the fresh air system, so as to improve the efficiency of the compartment Effect of Oxygen Concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

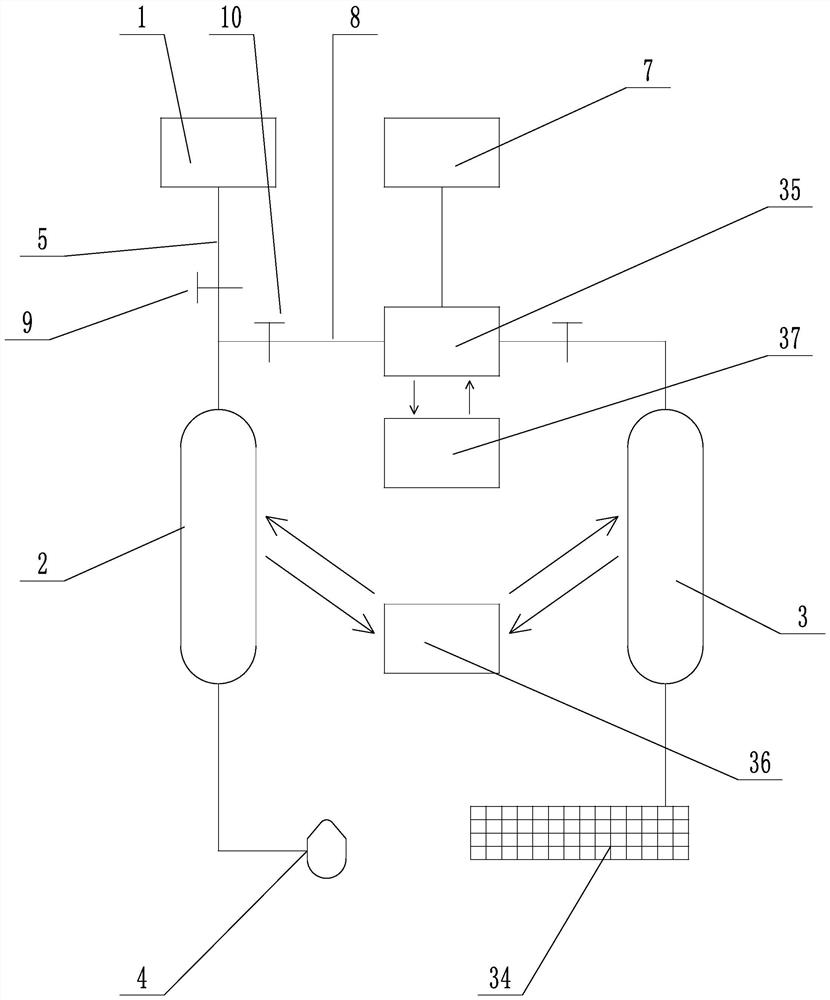

[0037] see figure 1 , an oxygen supply system with dual gas paths and multiple separators, comprising a spare air compressor 1, a first adsorption tower 2, a second adsorption tower 3, and a personal use terminal 4 connected to the output end of the first adsorption tower 2, and The oxygen diffusion terminal 34 connected to the output end of the second adsorption tower 3, the first gas path connection pipe 5 for communicating with the spare air compressor 1 and the first adsorption tower 2, the vehicle-mounted air compressor 7, and the vehicle-mounted air compressor for communicating with each other The second gas path connection pipe 8 of the machine 7 and the first adsorption tower 2, the second gas path connection pipe 8 for communicating with the vehicle-mounted air compressor 7 and the second adsorption tower 3, and the second gas path connection pipe 8 located on the first gas path connection pipe 5 The first air circuit valve 9 and the second air circuit valve 10 locate...

Embodiment

[0040] Embodiment principle:

[0041] When the EMU is in normal operation, the on-board air compressor 7 is running, and the air pressure monitoring device 37 monitors the air pressure output by the on-board air compressor 7. When the air pressure is high, the first air circuit valve 9 is closed, and the second air circuit valve 10 is opened. The air output by the vehicle-mounted air compressor 7 reaches the first adsorption tower 2 and the second adsorption tower 3 through cooling and filtering of the air pretreatment device 35 (prior art), and the first adsorption tower 2 and the second adsorption tower 3 After nitrogen and oxygen separation, it is output by the personal use terminal 4 and the oxygen diffusion terminal 34. The personal use terminal 4 can adopt forms such as oxygen masks, and the oxygen diffusion terminal 34 can adopt forms such as air outlets. internal oxygen concentration.

[0042] When the air pressure output by the vehicle-mounted air compressor 7 is rel...

Embodiment 2

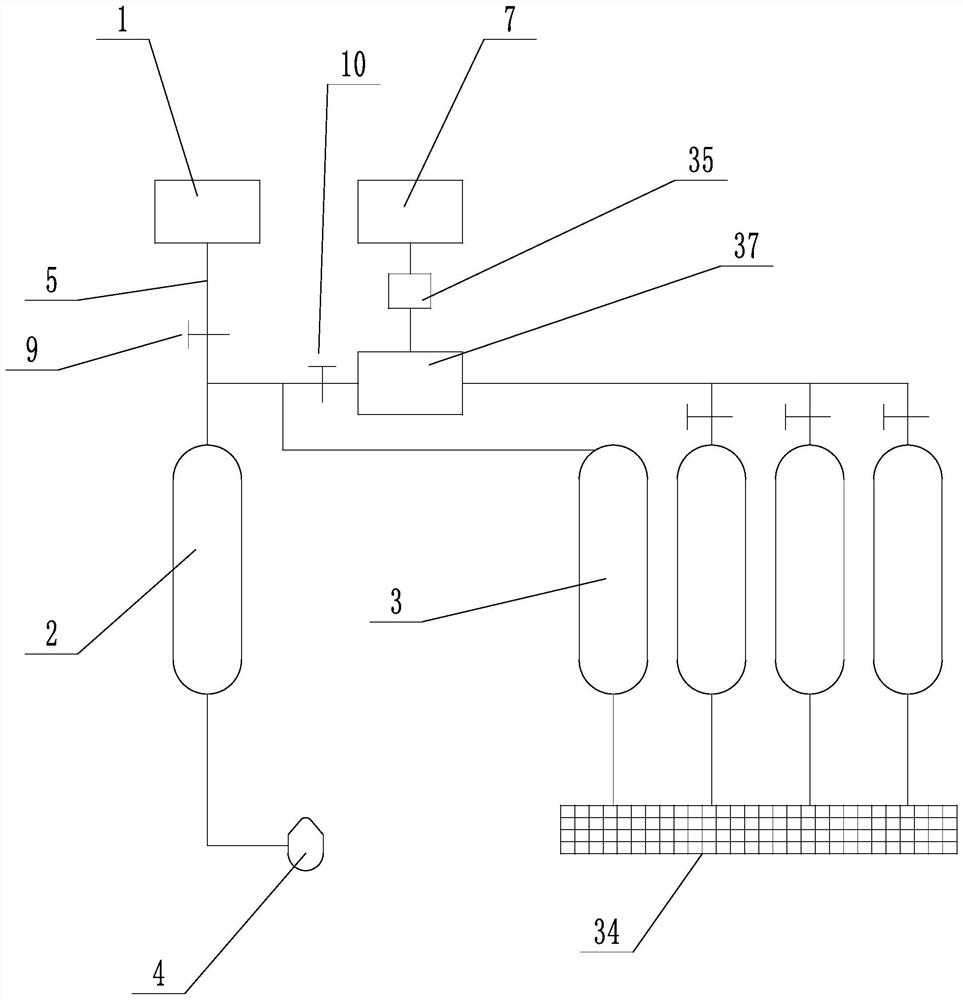

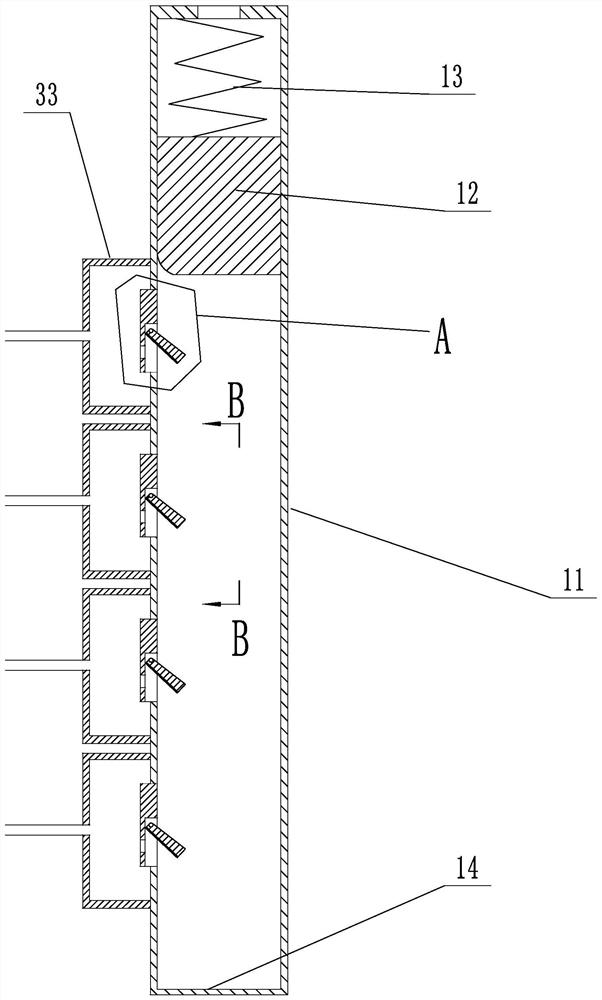

[0046] see Figure 2 to Figure 10 , an oxygen supply system with dual gas paths and multiple separators, comprising a spare air compressor 1, a first adsorption tower 2, a second adsorption tower 3, and a personal use terminal 4 connected to the output end of the first adsorption tower 2, and The oxygen diffusion terminal 34 connected to the output end of the second adsorption tower 3, the first gas path connection pipe 5 for communicating with the spare air compressor 1 and the first adsorption tower 2, the vehicle-mounted air compressor 7, and the vehicle-mounted air compressor for communicating with each other The second gas path connection pipe 8 of the machine 7 and the first adsorption tower 2, the second gas path connection pipe 8 for communicating with the vehicle-mounted air compressor 7 and the second adsorption tower 3, and the second gas path connection pipe 8 located on the first gas path connection pipe 5 The first air circuit valve 9 and the second air circuit v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com