Labyrinth sealing structure

A labyrinth sealing and sealing tooth technology, applied in the field of compressor sealing, can solve the problems of environmental pollution, interstage and shaft end leakage, and reducing the working efficiency of the compressor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

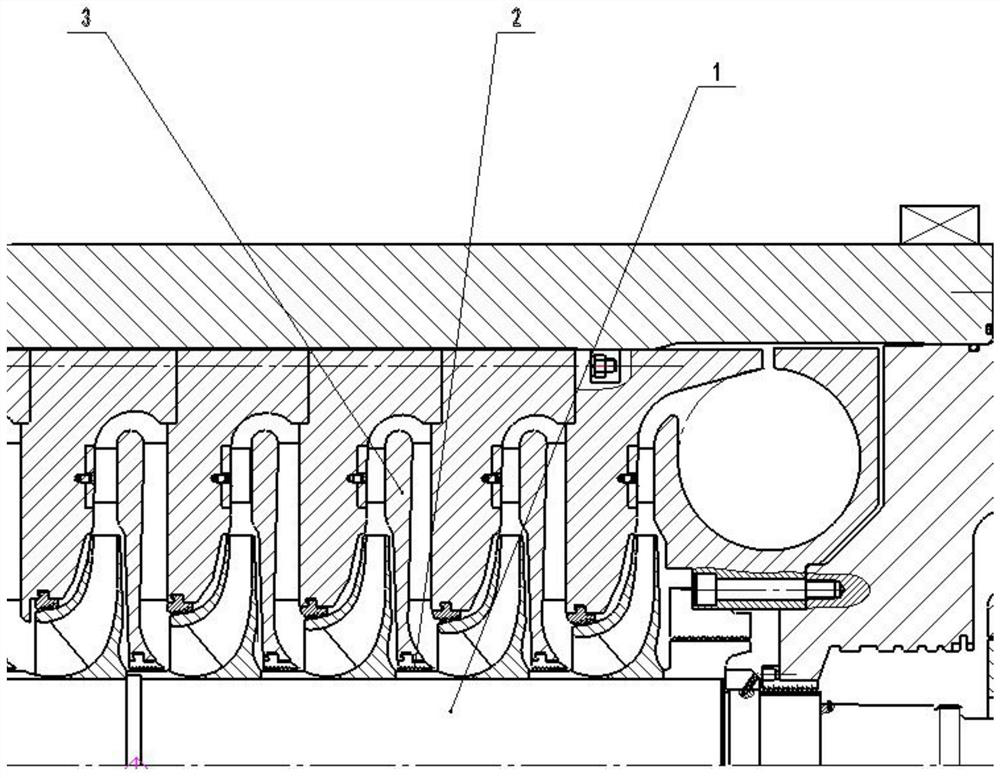

[0023] The smooth labyrinth seal in Example 1 adopts an overall structure, the teeth are arranged at equal intervals, the height of the sealing teeth is 3.5 mm, the distance between the teeth and the center line of the teeth is 4 mm, the angle between the two sealing teeth is 30 degrees, and the material is LD10. Aluminum, used for interstage seals before and after the impeller, can choose 4 teeth.

Embodiment 2

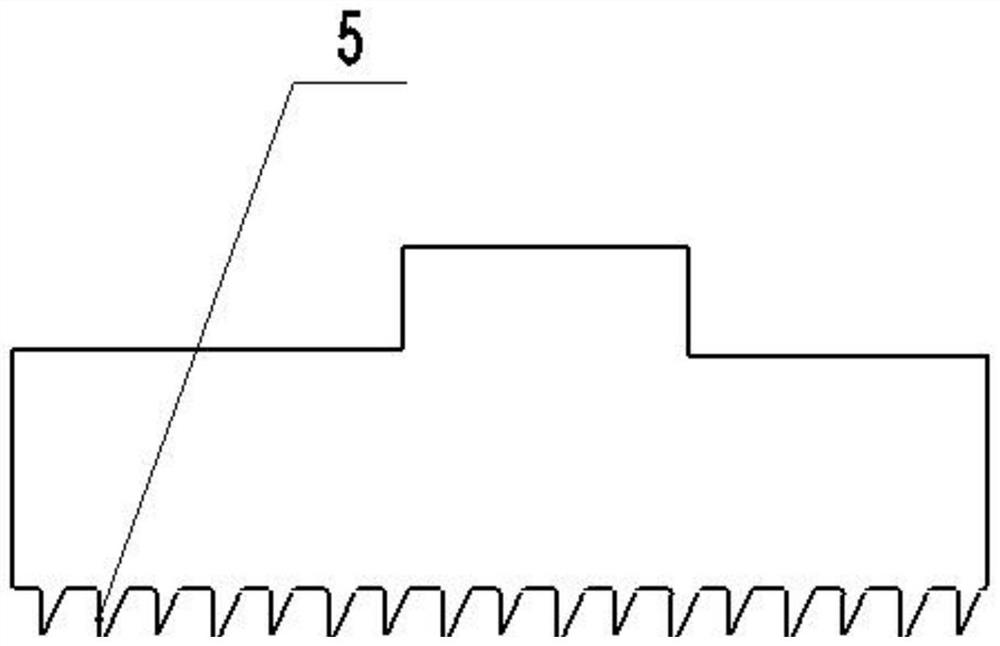

[0025] In the staggered labyrinth seal of Example 2, the protruding heights of the sealing teeth are different, the high and low teeth are arranged alternately, the height of the sealing teeth is 4 mm, the distance between the teeth and the center line of the teeth is 4.5 mm, and the angle between the two sealing teeth is 30 degrees. , the surface of the shaft is a special concave-convex groove. This structure of high and low teeth matched with the concave-convex groove makes the smooth sealing gap into a zigzag type, which increases the flow resistance and improves the sealing performance. It is used in the selection of materials for ethylene compressors. 5083 low-temperature aluminum, used for interstage seals before and after the impeller, and 5 teeth can be selected.

Embodiment 3

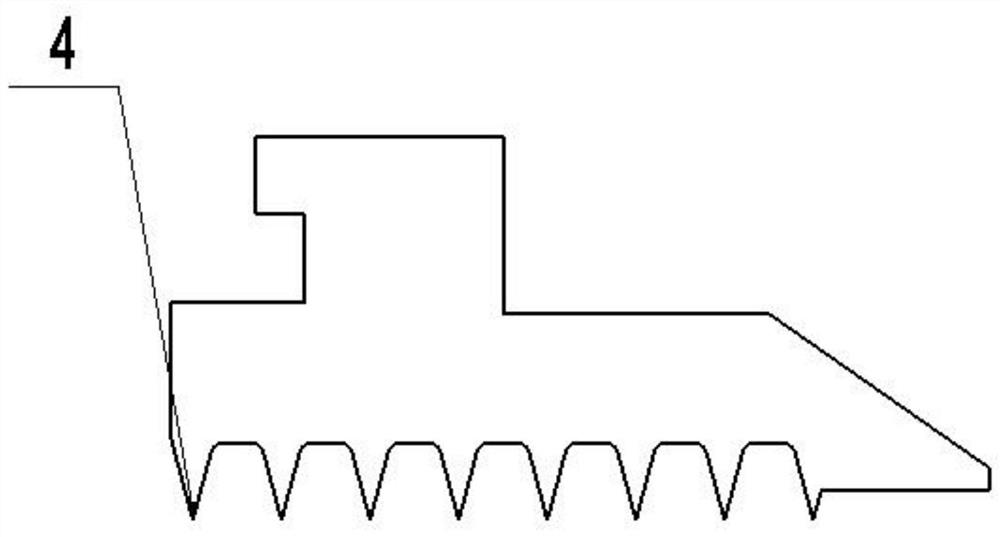

[0027] The stepped labyrinth seal in Example 3 has a change in the radial dimension, the drop between the previous tooth top and the next tooth top is 1 mm, the sealing tooth height is 5 mm, and the distance between the teeth and the center line of the tooth is 5 mm. The angle between the two sealing teeth is 30 degrees, and the material is ZL104 aluminum, which is used for shaft end sealing, and 25 teeth can be selected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com