Charger with automatic rotating shaft

A charger and shaft technology, applied in the field of chargers with automatic shafts, can solve the problems of inconvenient and stable adjustment of the charging port, affecting the convenience of charging applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

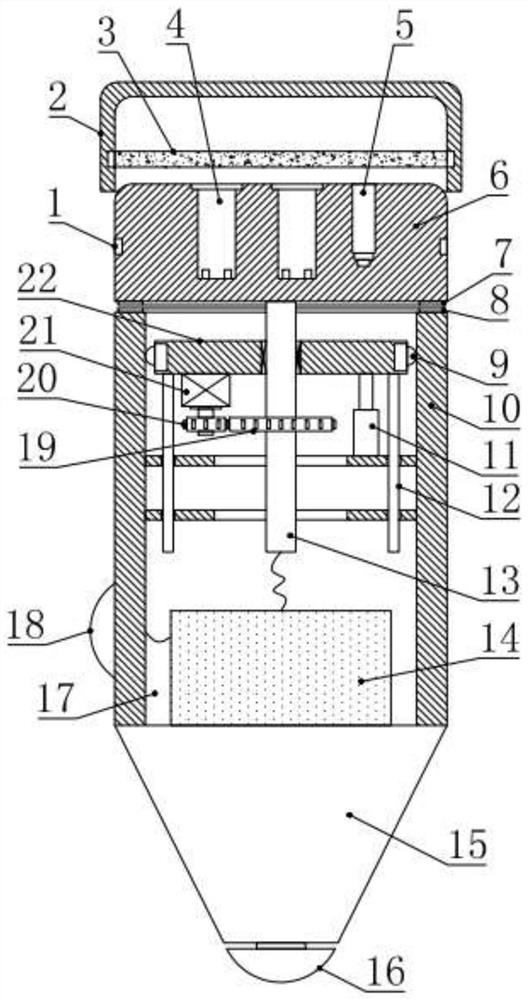

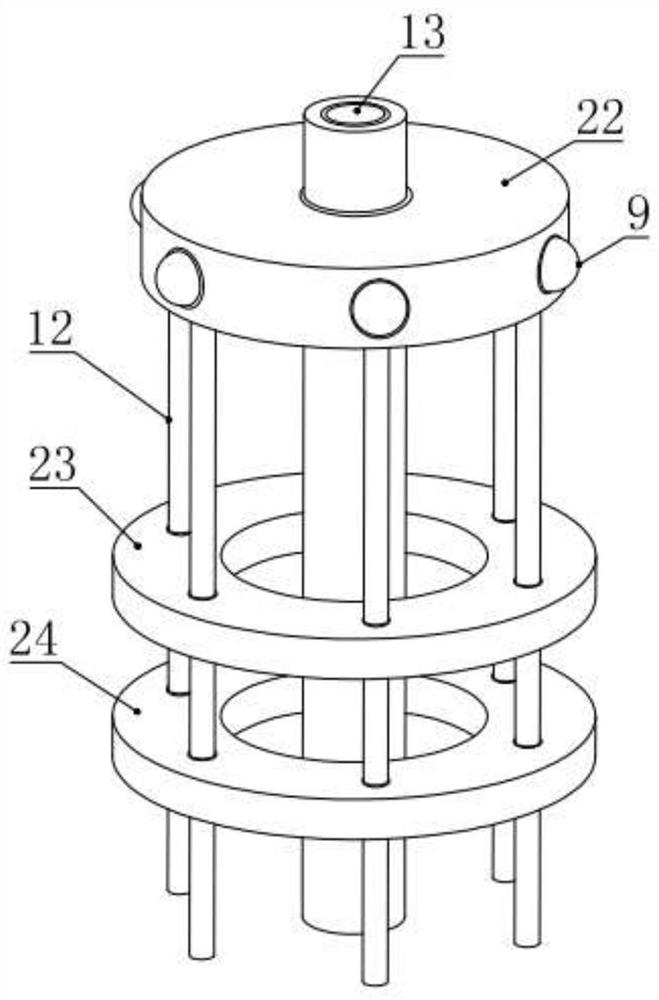

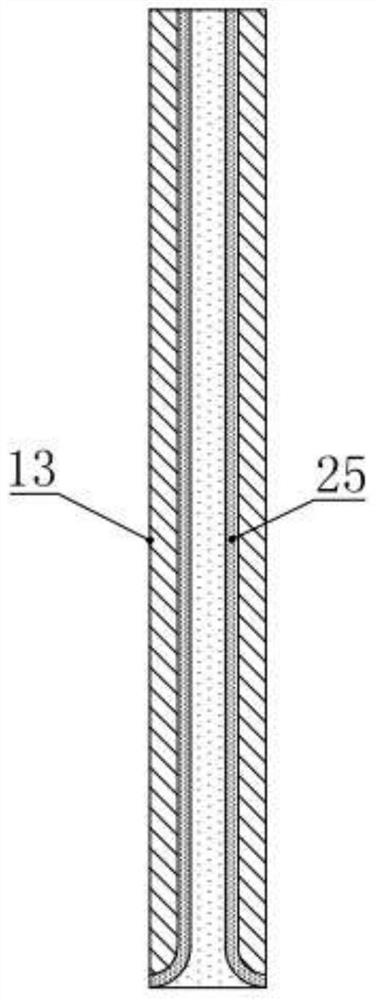

[0022] see Figure 1-2 , in an embodiment of the present invention, a charger with an automatic rotating shaft includes a charging body 6 and a charging head 10, the charging body 6 is co-located on the top of the charging head 10, and the charging body 6 is respectively provided with The USB interface 4 and the earphone charging port 5, the charging head 10 is provided with an installation cavity 17 with an upper opening, and a circuit board 14 is installed at the bottom of the installation cavity 17, and the circuit board 14 is electrically connected to the USB interface 4 and the earphone charging port 5 respectively. connection, the bottom of the charging head 10 is also equipped with a conical plug 15, the bottom of the conical plug 15 is equipped with a positive contact cap 16, and the lower side of the charging head 10 is also equipped with a negative contact 18, and the positive Both the contact cap 16 and the negative electrode contact 18 are electrically connected to...

Embodiment 2

[0026] see Figure 1-3 , the difference between this embodiment and embodiment 1 is:

[0027] In this embodiment, the charging body 6 and the charging head 10 are both cylindrical structures, and the bottom outer ring of the charging body 6 is provided with a first annular sealing ring 7, and the top outer ring of the charging head 10 is provided with The second annular sealing ring 8 vertically corresponding to the first annular sealing ring 7, through the setting of the first annular sealing ring 7 and the second annular sealing ring 8, can improve the sealing performance of the connection between the charging body 6 and the charging head 10, And after the charging body 6 and the charging head 10 are brought into contact, the charging body 6 is prevented from rotating.

[0028] The USB interface 4 can be a USB-B charging port, a Type-c charging port, or a Lightning charging port.

[0029] The charging body 6 can also be detachably covered with a sealing cover 2, the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com