Glass base plate box for liquid crystal display

A liquid crystal display, glass substrate technology, applied in instruments, nonlinear optics, packaging, etc., can solve problems such as substrate distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

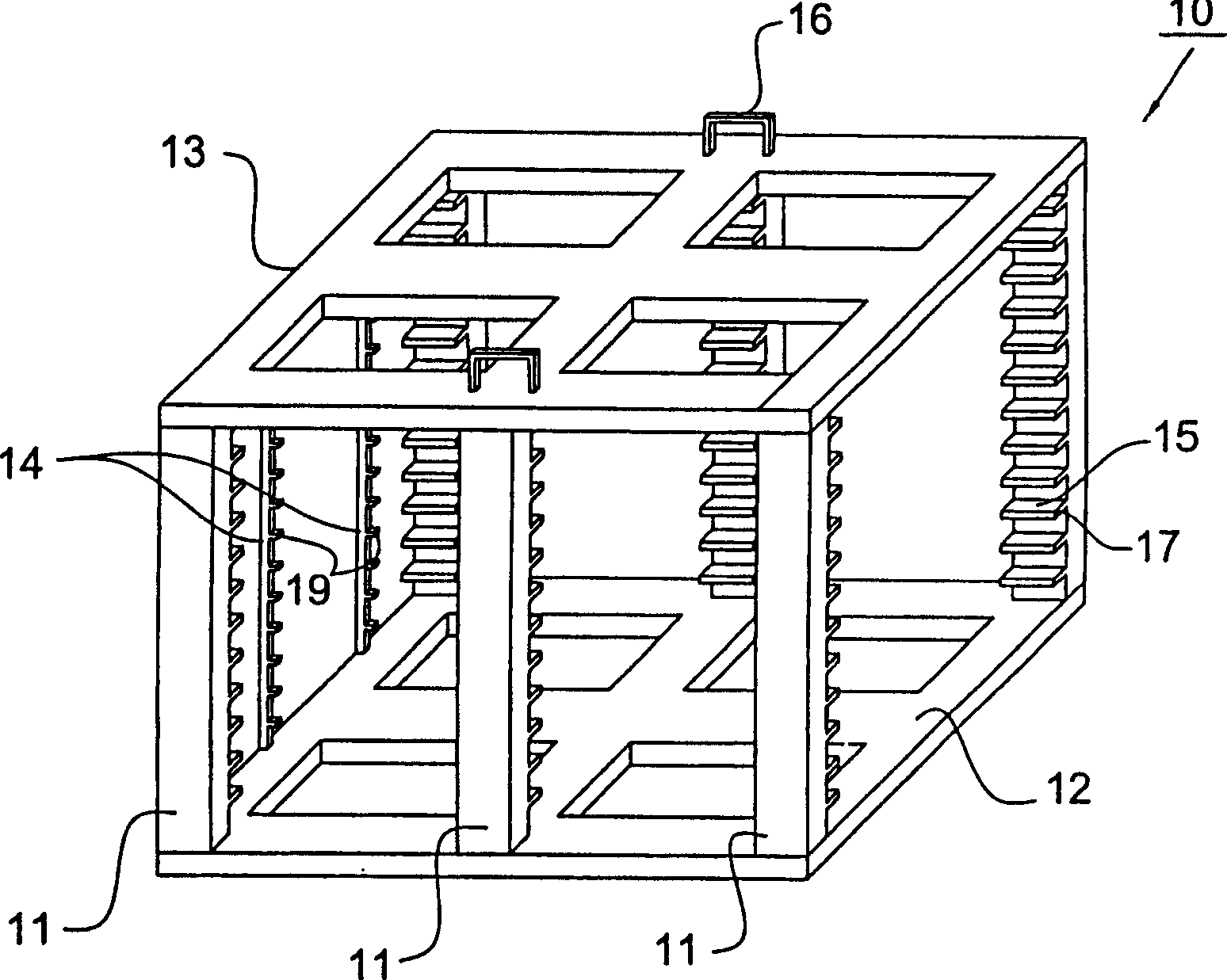

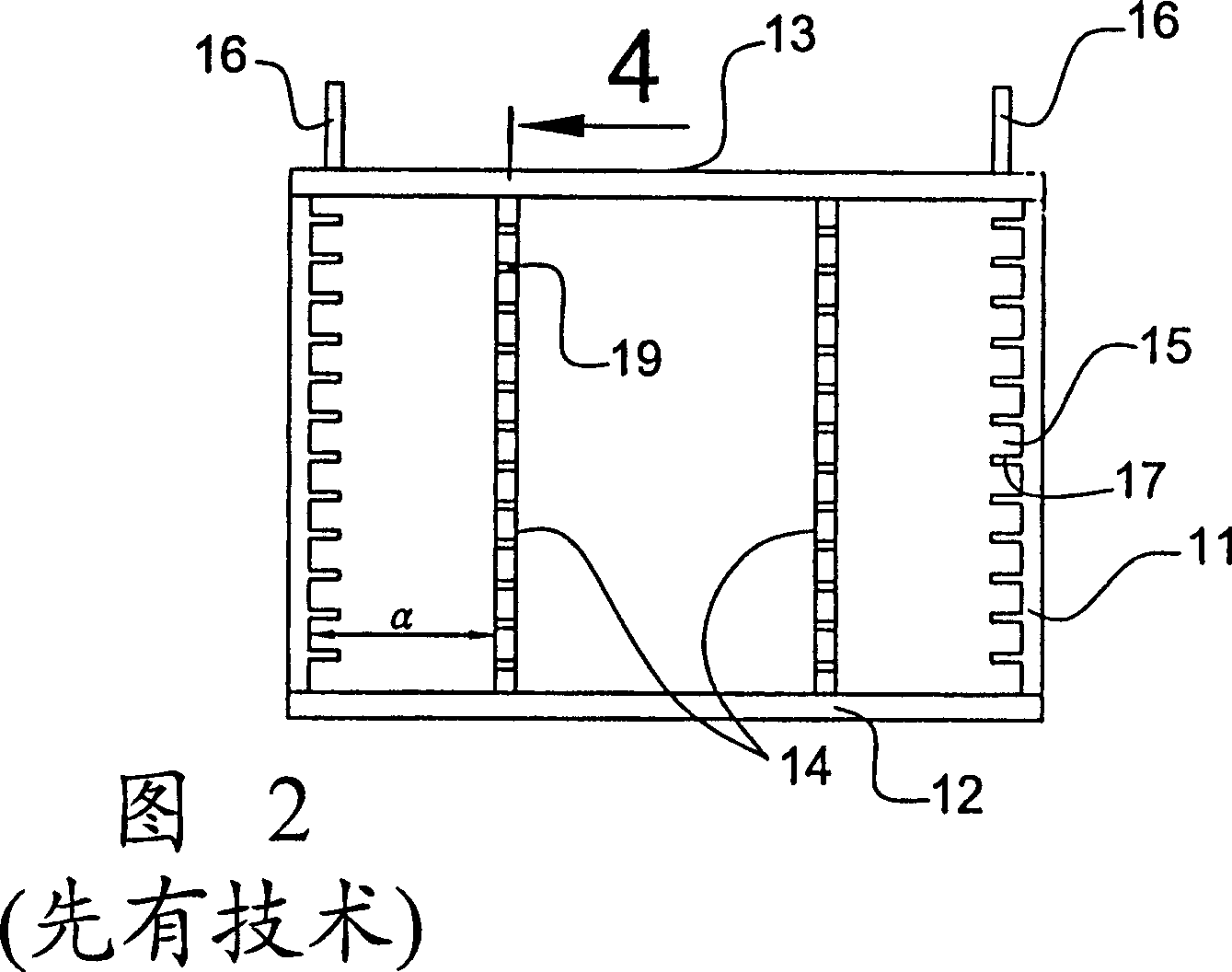

[0027] Referring now to FIG. 6, there is shown a liquid crystal display glass substrate cassette 50 in accordance with a first preferred embodiment of the present invention. The glass substrate box 50 includes a plurality of side plates 51 having a plurality of slots 55 formed by support members 57 for carrying the glass substrates, a bottom plate 52 and a top plate 53 . The substrate box 50 also includes two slidable end bars 54 and two handles 56, wherein the end bars 54 have stoppers 59, when the glass substrate is loaded in the substrate box 50, the end bars 54 The stopper 59 can be used to prevent the glass substrate from shifting, and the handle 56 can be used to carry the substrate box 50 conveniently.

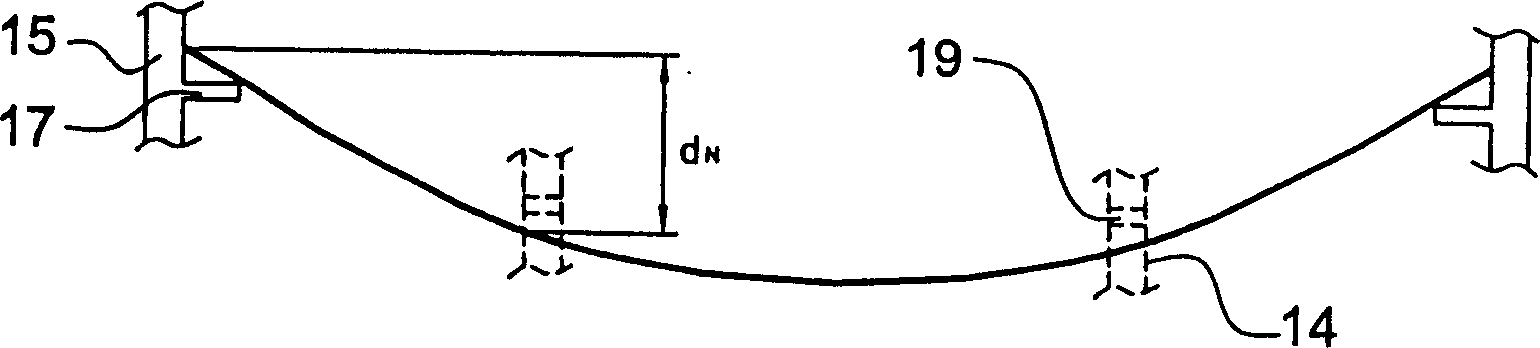

[0028] The feature of the present invention is that the end rod 54 can slide relative to the side plate 51 to adjust to match the natural drooping curve of the base plate to support the base plate. Preferably, the end rod 54 is placed between the groove 62 on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com