Auxiliary tool for horizontal correction of 3D glass hot bending

A level correction and auxiliary tooling technology, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., and can solve problems such as aggravation, deformation of the pressing plate, and poor shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

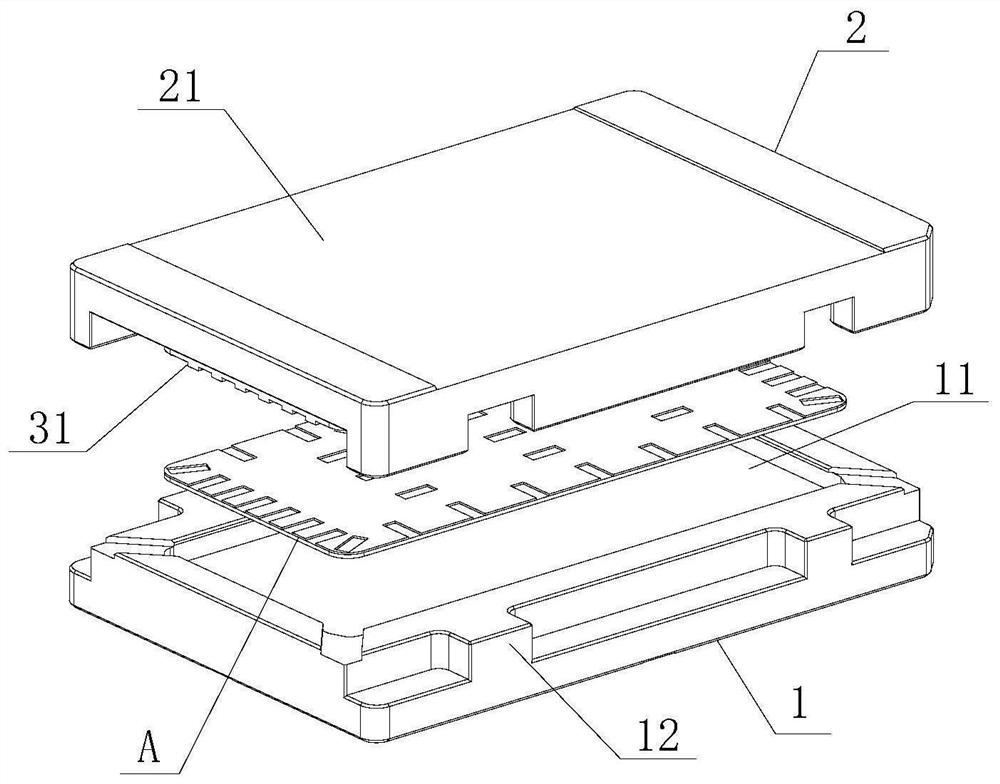

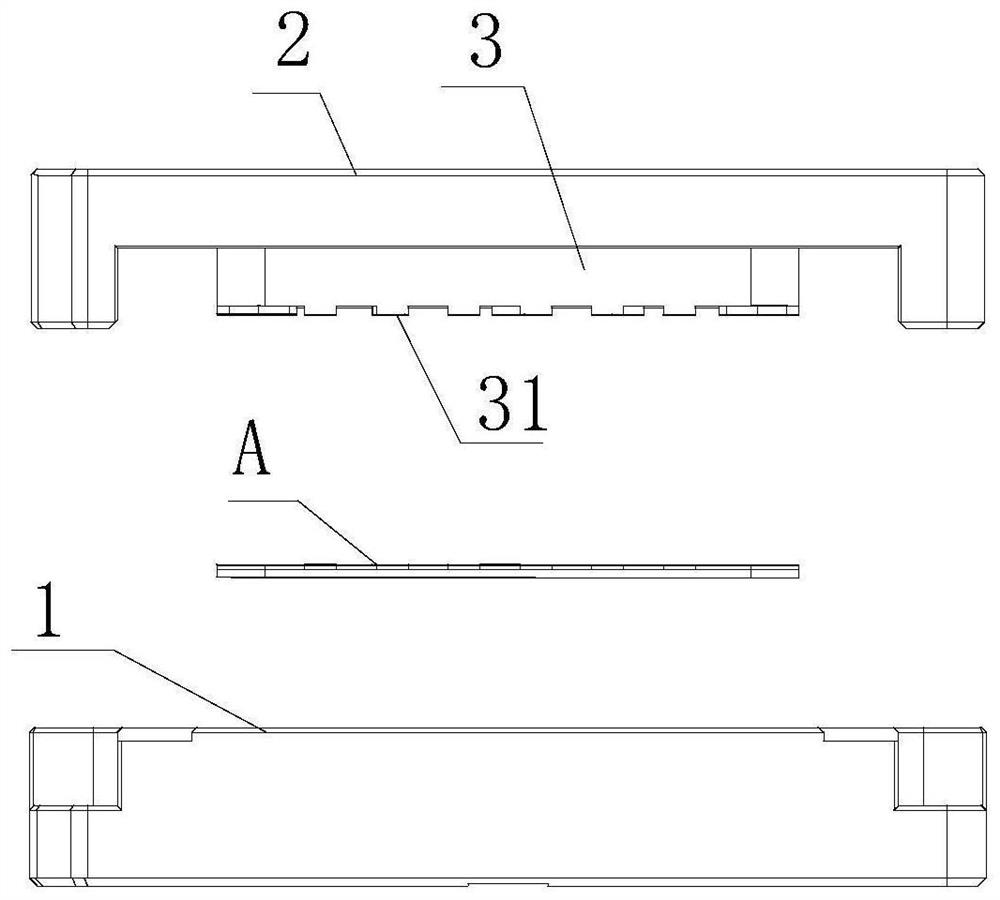

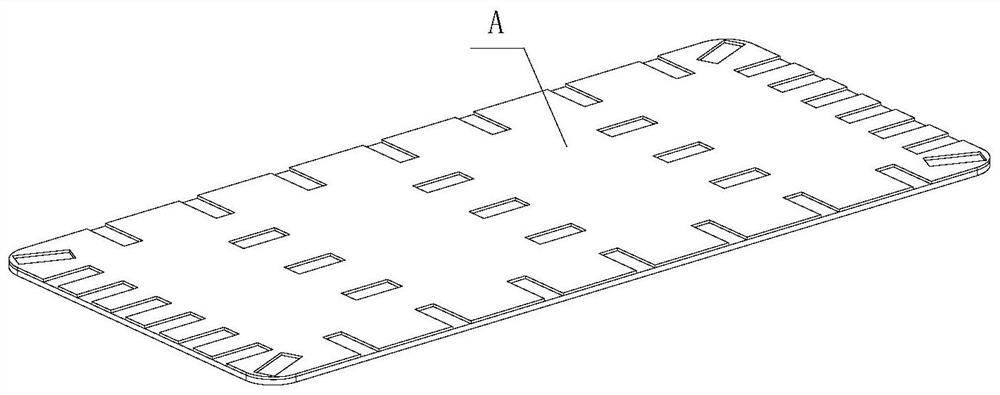

[0016] refer to Figure 1-3 , an auxiliary tooling for 3D glass hot bending level correction proposed by the present invention, comprising: an upper pressing head and a lower pressing seat 1, wherein: the upper pressing head includes a mounting plate 2 and a pressing block 3 fixed on the mounting plate 2, and the installation The plate surface of the plate 2 away from the side of the pressure block 3 has a mounting surface 21 for contacting the pressure plate; the end surface of the pressure block 3 away from the side of the mounting plate 2 is provided with several raised bosses 31; the end faces of each boss 31 Located on the same plane, the plane where the end surfaces of the bosses 31 are located is parallel to the mounting surface 21 . The lower pressure seat 1 has a positioning groove 11 for the pressure block 3 to enter, and the groove bottom of the positioning groove 11 is a plane parallel to the mounting surface 21; the specific usage method is as follows:

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap