Anti-blocking cutter head nozzle

An anti-clogging, cutter head technology, used in mining equipment, earth-moving, tunnels, etc., can solve the problem of clogging of cutter head nozzles, and achieve the effect of reducing mud cake and cutting tool wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

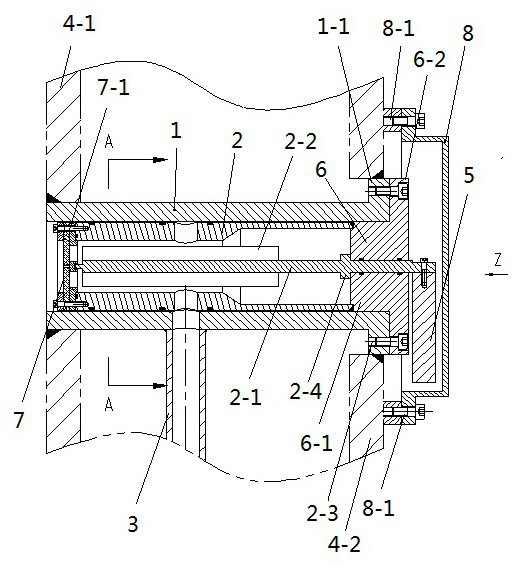

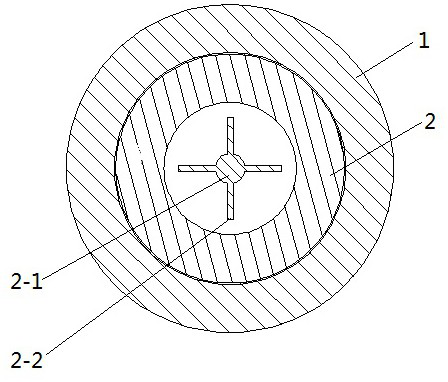

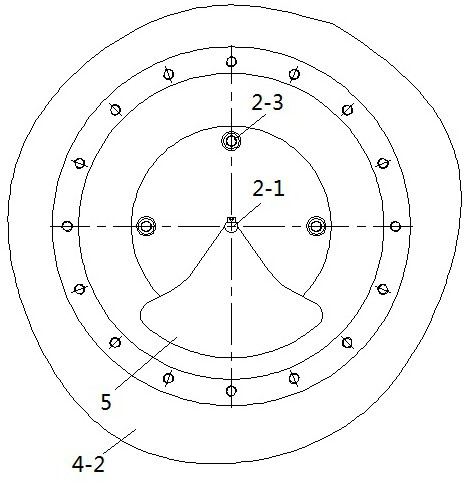

[0034] Embodiment 1, a kind of anti-clogging cutter head spout, such as figure 1 As shown, it includes a cylinder communicated with the injection port on the front panel 4-1 of the cutterhead, and the cylinder is communicated with the liquid supply pipe 3, and the liquid supply pipe 3 sprays foam agent to the front of the front panel 4-1 of the cutterhead through the cylinder or bentonite. A rotating shaft 2-1 with blades 2-2 is arranged in the inner cavity of the cylinder, and a weight 5 is arranged at the rear end of the shaft 2-1, and the shaft 2-1 is connected to the non-rotary part of the weight 5 At the position of the center of gravity, a sealing structure is provided between the weight 5 and the inner cavity of the barrel, and the weight 5 is covered with a protective housing 8 whose inner cavity is larger than the rotation space of the weight.

[0035] Such as Figure 4 and Figure 5 As shown, the cutter head rotates clockwise, and the weight 5 always points vertic...

Embodiment 2

[0042] Embodiment 2, an anti-clogging cutter head nozzle, the blade 2-2 is a helical blade, and when the weight 5 drives the shaft 2-1 to rotate, the slag discharge direction of the helical blade is the same as the liquid outlet direction of the inner cylinder 2 . When the blades 2-2 rotate, they can both effectively stir and discharge the slag in the inner tube 2 to the outside.

[0043] Other structures of this embodiment are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com