Gypsum board drying device and drying method thereof

A drying device and gypsum board technology, applied in the direction of drying gas arrangement, progressive dryer, drying solid materials, etc., can solve the problems of inspection time lag and quality problems that cannot be found in time, achieve high adjustment accuracy and improve online production quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0011]Embodiments of the present invention will be described below with reference to the drawings. It should be noted that the features of the present invention in the present invention can be combined with each other in the case of an unable conflict.

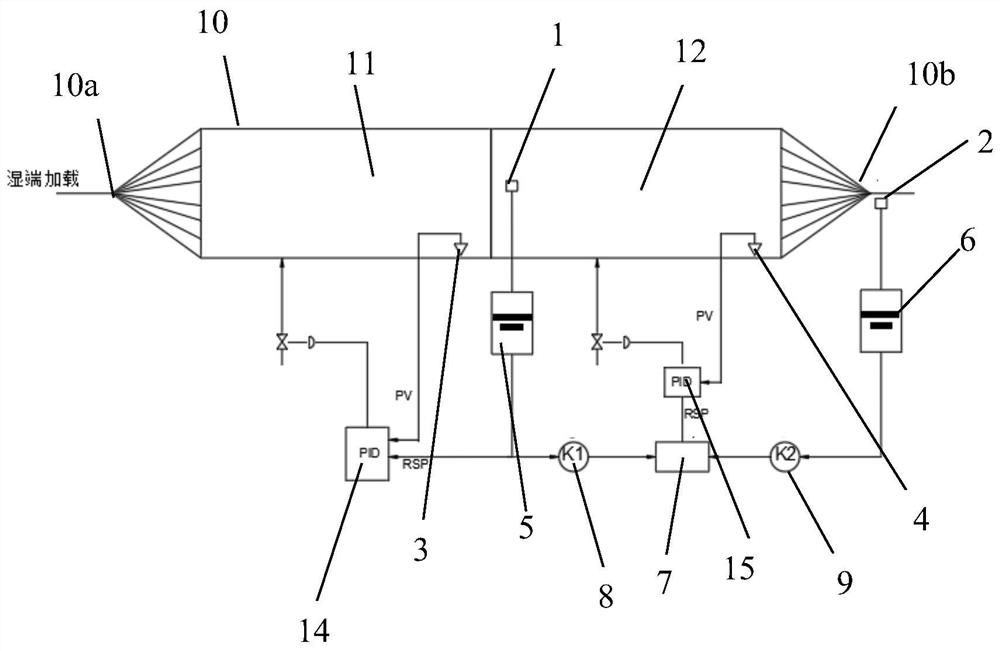

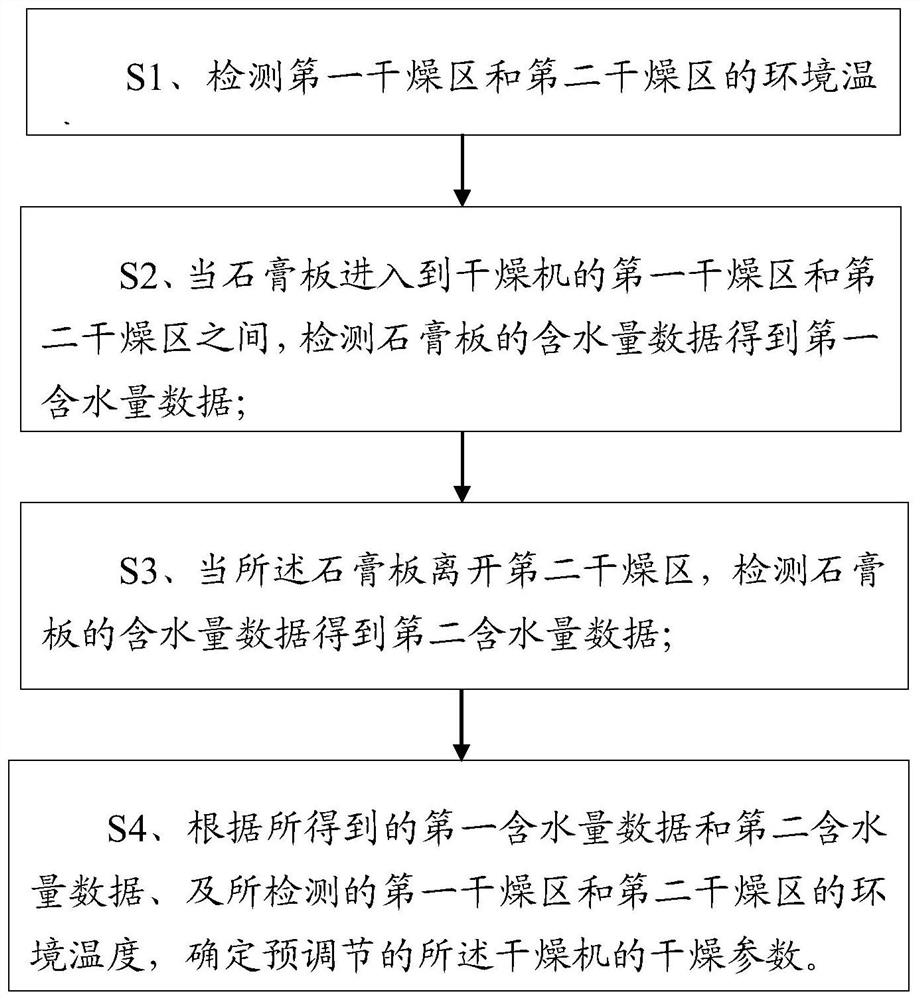

[0012]Such asfigure 1 As shown, the embodiment of the present invention provides a gypsum plate drying device, including a dryer 10 for drying the gypsum plate, the dryer 10 includes an inlet end 10a and an outlet end 10b, located between the inlet end 10a and the outlet end 10b. The first drying region 11 and the second drying region 12 are first. The gypsum board is dried from the inlet end 10a to the dryer, and the output is dried from the outlet end 10B. In this embodiment, the first drying region 11 is a low temperature drying area, the drying temperature ranges from 200 degrees; the second drying region 12 is a high temperature drying area, and the drying temperature ranges from 200 to 300 degrees. In other embodiments, the dryin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap