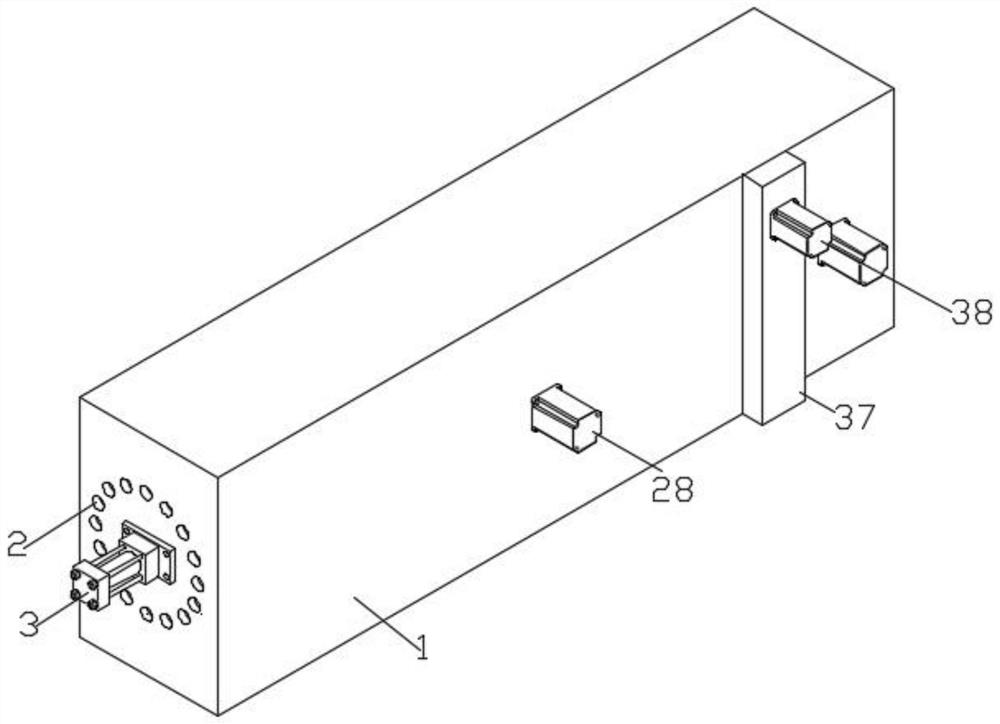

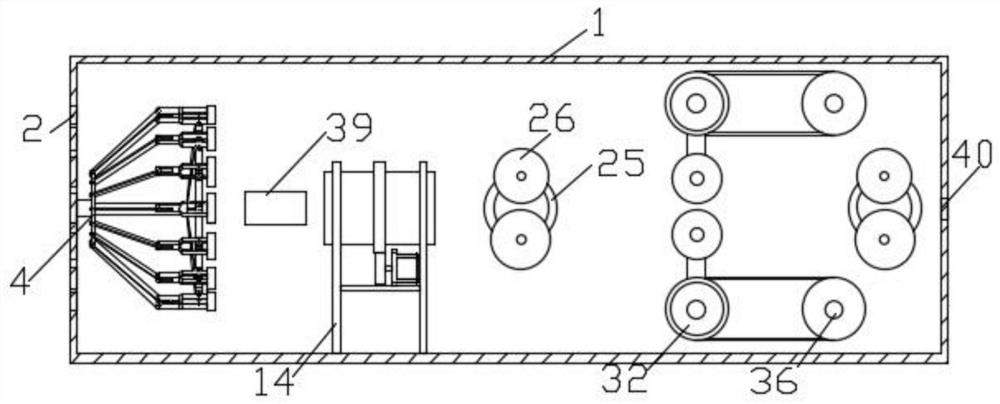

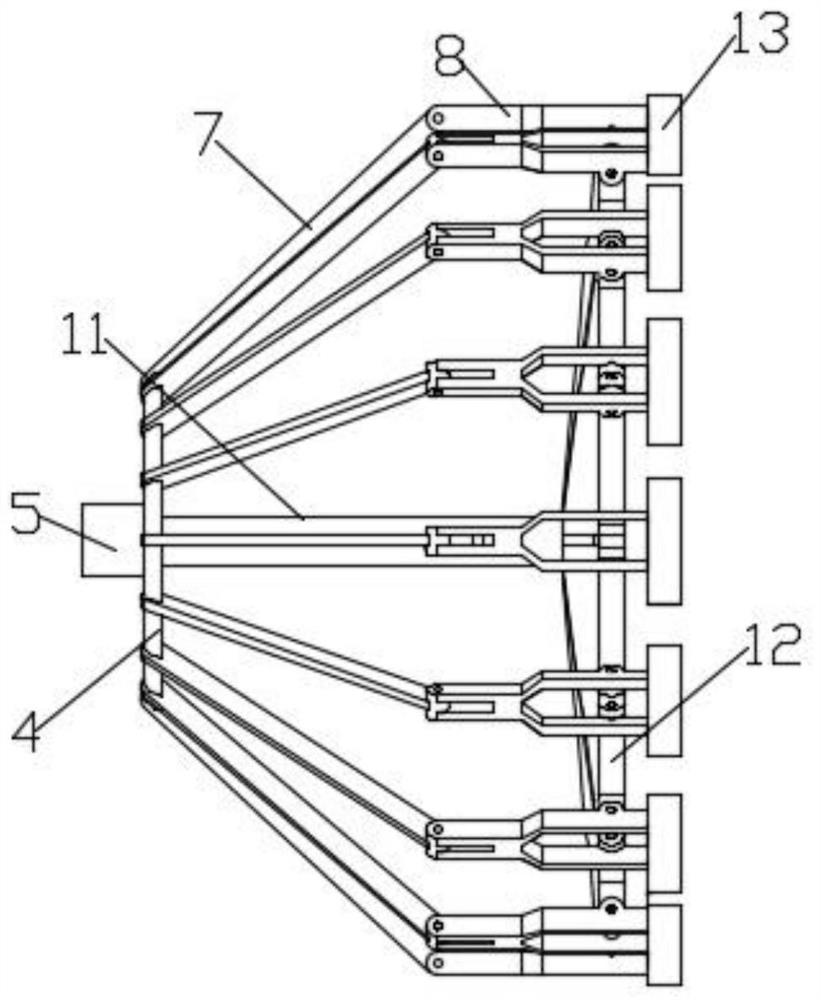

[0004] The object of the present invention is to provide a steel strand stress relief device for bridges and its working method, which solves the following technical problems: (1) by inserting a plurality of steel strands into a plurality of wire entry holes one by one, the steel strands After passing through the wire hole and through the steel strand sleeve, the installation cylinder is opened, the

piston rod of the installation cylinder shrinks and drives the guide rod to move horizontally, the guide rod slides along the guide sleeve, the guide rod drives the second annular plate to move horizontally, and then the rotating seat and the rotation The arm rotates in cooperation, the rotating seat drives the steel strand sleeve to rotate, and the steel strand sleeve drives the steel strand to rotate. Through the above structure, the steel strand stress relief device for the bridge can gather multiple strands of steel strand into one strand, and then It is possible to carry

out stress relief work on multiple strands of steel strands at the same time to ensure that the stress relief of multiple strands of steel strands is carried out simultaneously; The steel strand passes through the rotating cylinder, and the three guiding cylinders in the rotating cylinder are opened. The

piston rod of the guiding cylinder pushes the guiding block, and the guiding block slides along the guiding rod and drives the two second rotating rods to rotate. The two second rotating rods cooperate with the four The first rotating rod drives the limit bar to move in the rotating cylinder, and the three limit bars in the rotating cylinder move towards each other. The limit bar contacts the gathered steel strands, the

drive motor is turned on, and the output shaft of the

drive motor drives the gear. Rotate, the gear cooperates with the gear ring to drive the rotating cylinder to rotate, the rotating cylinder drives the three limit bars to rotate, and the three limit bars drive the gathered steel strands to rotate. Through the above structure, the bridge uses a steel strand stress relief device The gathered steel strands can be limited to prevent the situation that the steel strands cannot be gathered due to their own stress before the stress is relieved. The three limit bars can meet the limit of steel strands of different diameters. At the same time, after the limit The steel strands are driven to rotate through three limit bars, and several steel strands are twisted into bundles to prevent the individual steel strands from retracting under the influence of stress, and to facilitate subsequent stress

relief work; (3) Gathering The finished steel strand first passes between the two stress-relief rollers on the side close to the

rotating drum, then passes between the two limit rollers, and finally passes through the two stress-relief rollers on the side near the outlet hole, and opens the two A motor is installed, and the output shaft of the motor is installed to drive the central gear to rotate, the central gear meshes to drive the two planetary gears to rotate, the two planetary gears drive the two rollers to rotate, the two rollers drive the two stress relief rollers to rotate, and the two stress relief The roller drives the gathered steel strand to rotate, and the limit motor is turned on, the output shaft of the limit motor drives one of the pulleys to rotate three times, the two pulleys three drive the belt two to rotate, the three pulleys drive the axis rod to rotate, and the axis rod drives the

pulley two Rotation,

pulley 2 drives

pulley 1 to rotate through belt 1, pulley 1 drives the epicyclic roller to rotate, epicyclic roller drives two right-angle connecting blocks to rotate, right-angle connecting block drives the connecting arm to rotate, and the two connecting arms drive the limit roller to rise and fall periodically. A limit roller pulls the gathered steel strand up and down periodically, and the steel strand is conveyed out from the outlet hole after the stress is relieved. Through the setting of two sets of rotatable stress relief rollers, the steel strand can be repeated in different directions. guide, and at the same time cooperate with two limit rollers that can be raised and lowered periodically, which can drive the steel strand Repeated lifting to effectively eliminate the stress of steel strands

Login to View More

Login to View More  Login to View More

Login to View More