Plastic bag taking device for rice packaging bags

A technology of retrieving device and plastic bag, which is applied in packaging and other directions, can solve the problems of rice leakage, inability to guarantee the shape and position of the bag mouth, misalignment between plastic bags, etc., to avoid waste, fast and efficient delivery, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

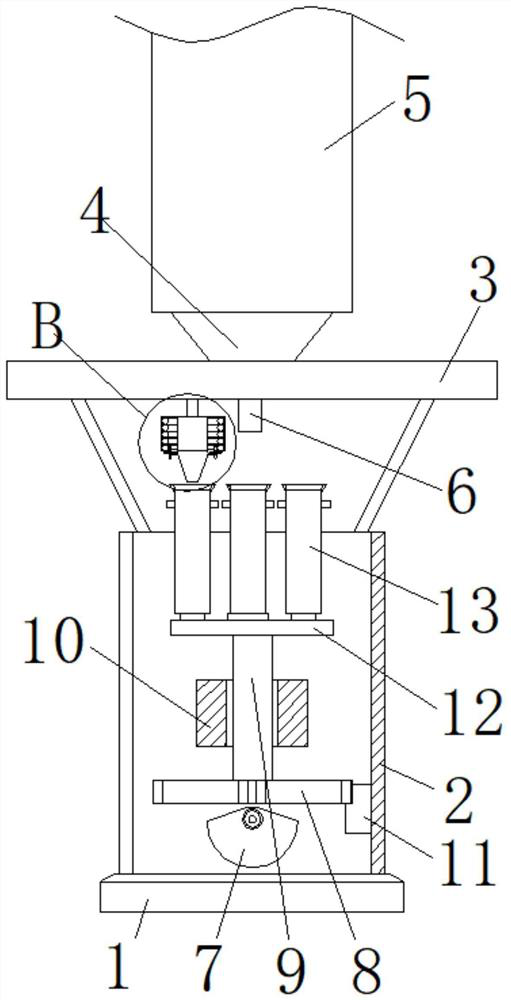

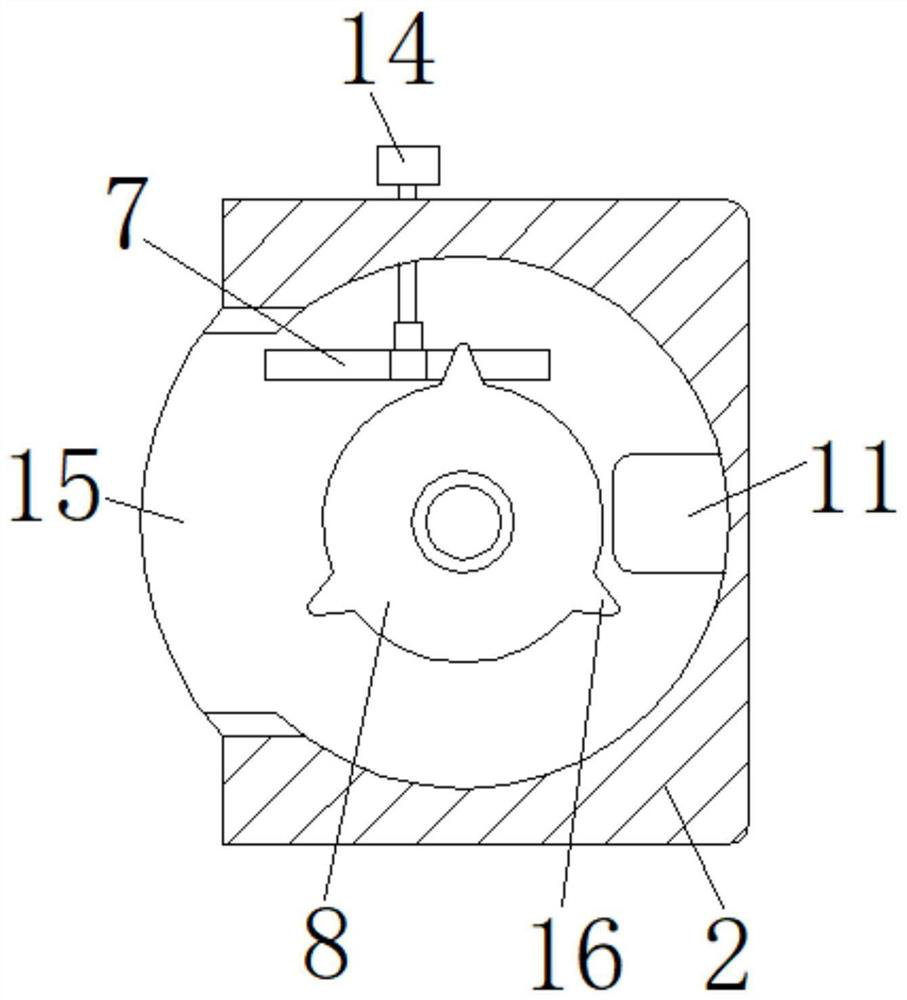

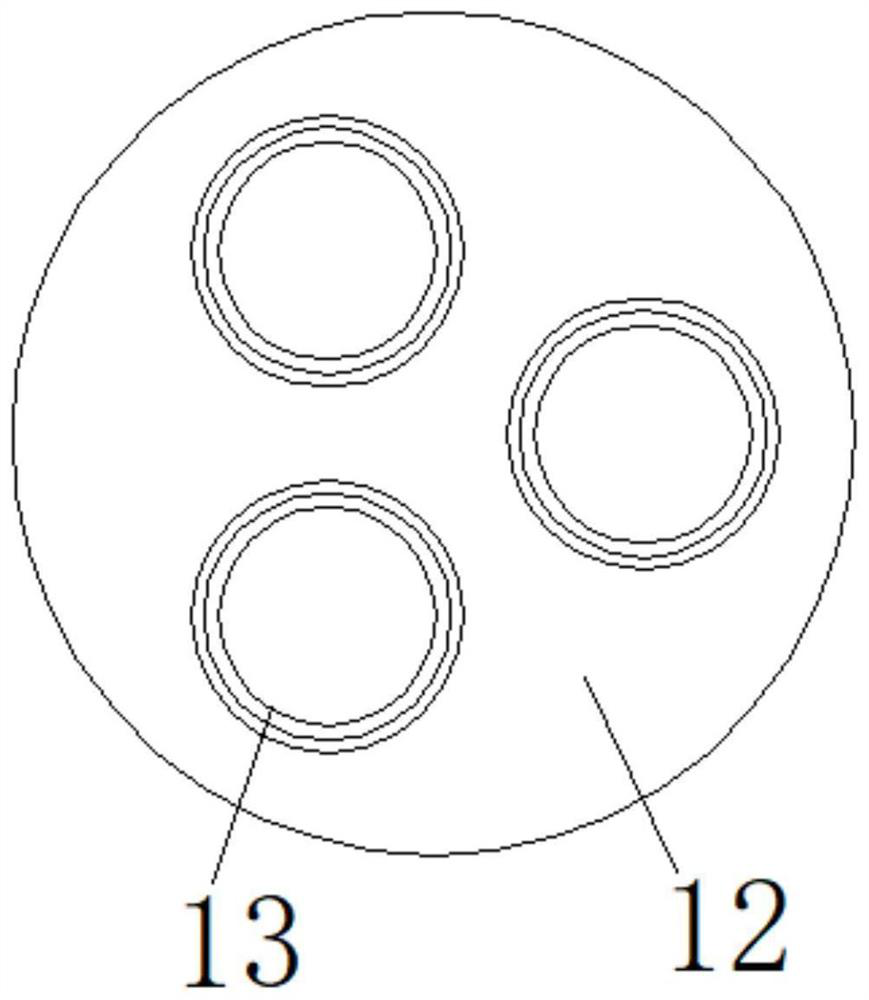

[0028] In this example, refer to Figure 1-7 , a plastic bag retrieving device for rice packaging bags, comprising a base 1, a fixed cylinder 2 is arranged on the base 1, a fixed plate 3 is installed on the top of the fixed cylinder 2 through connecting ribs, and a funnel 4 is arranged at the center of the fixed plate 3 , the funnel 4 is provided with a feeding bin 5, and the bottom of the funnel 4 is provided with a discharge pipe 6, combined with the attached figure 2 , The inner wall of the fixed cylinder 2 is provided with an outlet 15, and the outlet 15 provided is convenient for manual operation.

[0029] The lower half of the side wall of the fixed cylinder 2 is rotatably equipped with a cam disc 7, a guide block 10 is arranged at the middle position, a motor 14 is arranged outside the fixed cylinder 2, and a drive shaft is provided at the output end of the motor 14, and the end of the drive shaft passes through The shaft coupling is concentrically fixedly connected w...

Embodiment 2

[0032] The bottom surface of the fixed plate 3 is provided with a limit mechanism directly above one of the straight cylinders 13. The limit structure is composed of a storage tube 17, a cone block 20, a movable support 21, and a sliding ring 24. The bottom of the fixed plate 3 is provided with a cylinder. The output end of the cylinder is provided with a cylinder rod 18, and the lower end of the cylinder rod 18 is docked on the storage tube 17. The telescopic promotion of the cylinder rod 18 is utilized to realize the up and down lift of the storage tube 17 . The mouth of the storage tube 17 is downward, and the center of the top wall of the storage tube 17 is downwardly provided with a straight column 19, and the lower end of the straight column 19 is equipped with a cone block 20, and the sliding ring 24 is inserted in turn along the cylinder of the straight column 19. Stacked in the storage tube 17 , the two sides of the cone block 20 are respectively provided with rotatab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com